Fiber laser technology is widely used in the field of laser cleaning and rust removal because of their high removal efficiency, low price, long lifespan and easy operation. Fiber laser can be subdivided into pulsed fiber laser and continuous fiber laser. Generally speaking, laser rust removal can use both pulsed fiber laser and continuous fiber laser.

So, What is the Difference Between these two Kinds of Lasers?

Continuous fiber laser for rust removal applications in the market mainstream product power range between 1,000 watts and 6,000 watts,it’s cost-effective, for example, a power of 3,000 watts of laser rust removal machine price is about 10,000USD. At present, continuous fiber laser is basically a single-mode laser and the laser beam type is gaussian light. Gaussian beam energy distribution is more uneven, the middle energy is too high, will cause local temperature is too high and thus cause some damage to the substrates to be cleaned.

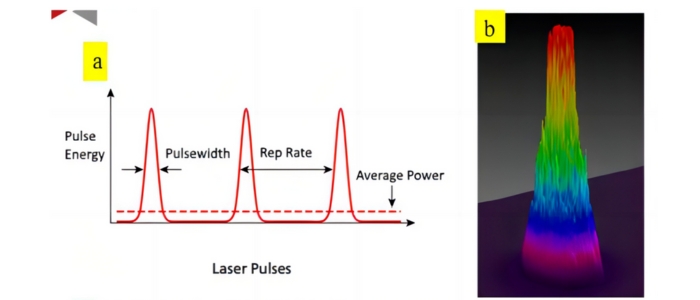

Pulsed fiber laser cleaning machine in the market mainstream product power range between 100 watts and 500 watts, the price is more expensive, for example, a power of 300 watts or so laser cleaning mold machine price is about 20,000USD or so, but more than 100 watts of pulsed lasers not only Gaussian light, there is also a flat-top light. The energy distribution of the flat-top beam is so uniform, basically there is essentially no damage to the substrate. We more recommed pulse fiber laser to clean precision instruments and high-precision products.

As for continuous laser cleaning machines, MOZLASER only recommends them for rust removal applications. Comparing to continuous fiber laser, pulsed fiber laser has a very low absorption rate for contaminants and a high absorption rate for base metals. Therefore, the pulsed laser can be transmitted through the contaminant layer to the base metal, which heats up instantly when the base metal absorbs the laser energy, creating thermal stress. Pulsed laser light is radiated in beams of light energy, so the base metal produces a very high frequency “vibration benefit”. The combined effect of thermal stress and vibration removes the contaminants. As long as the laser energy density is controlled to ensure that the temperature of the base metal does not rise above the melting point,no damage is caused to the base metal.

Laser Rust Removal Machine Types

Laser rust removal is a high-tech rust removal method that has emerged in the past few years. Compared with the traditional methods such as manual grinding and sand blasting, laser rust removal is faster and more efficient. Moreover, it can be used with air extraction device to remove the residue after rust removal, which is more environmentally friendly, green and pollution-free. Now the popular laser rust removal equipment on the market is mainly divided into continuous fiber laser rust removal machines and pulsed fiber laser rust removal machines according to the laser wavelength and mode.

Continuous fiber laser rust removal machines

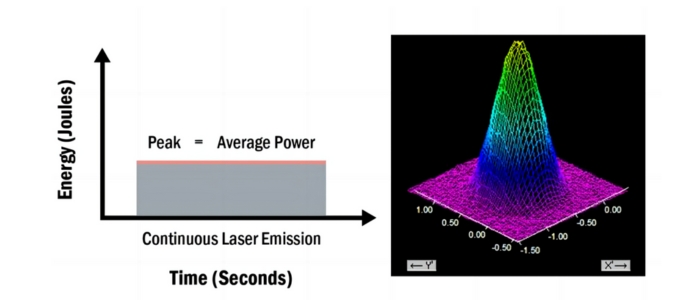

Continuous fiber laser rust removal machines adopt CW fiber laser source with high average output power, which realizes laser output through continuous excitation ability, which means that the laser is turned on until the optical knife stops, CW laser usually has lower peak power and higher average power. CW fiber laser spot type is generally Gaussian, using continuous laser cleaning machine, generally will continue to heat the material substrate, and the substrate damage of about 5μm.

Pulse fiber laser rust removal machines

Pulse fiber laser rust removal machines adopt pulse fiber laser source with very high peak power, which is different from continuous fiber laser, pulse fiber laser has a light frequency called pulse width, the radiation effect of pulse laser is similar to the sunlight that keeps flashing, radiating light energy in beams and beams, and it can produce high-frequency vibration. The pulsed laser descaling process is a vibration plus burning effect, so it can descaling at a much lower temperature rise, effectively protecting the substrate.

How to Choose a Fiber Laser Rust Removal Machine?

Materials you cleaning

If you just want to remove rust from common metal materials, such as outdoor doors, windows, steel structures, ship hulls, construction metals, etc., and your materials can accept certain thermal effects and damage of about 5μm, you can choose CW fiber laser rust removal machine because it is cheaper and the efficiency of the rust removal is very high, and it has higher average laser power which makes it possible for us to remove rust from the cleaned material. The higher average laser power allows us to extend the cleaning range to achieve higher cleaning efficiency

If you are cleaning very high precision metal products, such as injection molds, tire molds, vehicle engines, etc., we recommend you to use pulsed fiber laser rust removal machine, its advantage is that the laser spot is flat-topped light, almost no damage to the metal substrate. Its advantage is that the laser spot is flat-topped, which will hardly damage the metal substrate. Moreover, the peak power is very high, which can gasify the rust on the metal surface instantly.

Safety and certificate

Internationally, laser products are classified into different safety levels according to their wavelength, maximum output laser power or energy. CW fiber laser rust removal and pulse fiber laser rust removal are classified as IV laser level for working with laser power above 100W. Both the United States and Canada require safety certifications for laser equipment. In the US and Canada, FDA approval is required, while the EU region requires CE marking of the manufacturer.

MOZLASER Laser has sold many laser cleaning machines to more than 100 countries and regions, already have the FDA registration and certification,CE certification, and SGS factory report.

Cleaning efficiency and budget

Fiber laser rust removal machines are based on the principle that the laser converts electrical energy into laser energy and then acts on the metal surface to get rid of the surface rust, so different laser powers have different cleaning efficiency, total power and price, if you need to buy for large-scale industrial rust removal, we recommend higher laser power, 3000W-6000W CW fiber rust removal machines, which can be used for large-scale industrial rust removal, we recommend higher laser power, 3000W-6000W CW fiber rust removal machines. If you need to buy it for large scale industrial rust removal, we suggest higher laser power, 3000W-6000W CW fiber rust removal machine, or 500W-100W pulse fiber laser rust removal machines. If you just use it for small amount of rust removal, we suggest you to buy a small power laser rust removal machine to save the cost of purchase. Please download and view the MOZLASER data file below for different cleaning efficiencies of different power lasers for rust removal and other materials.

RFQs of Fiber Laser Rust Removal

1.What is the wavelength of the fiber laser and what is the different with Co2 laser?

The wavelength of the fiber laser is 1064nm, Co2 laser wavelength is 10640nm. The wavelength determines the absorption rate of different materials. Therefore, CO2 lasers are generally used for cutting and marking of non-metallic materials. Fiber laser is generally used for cutting, marking, cleaning and descaling of metal materials.

2.What is the laser class of the fiber laser rust removal machine? What kind of protection do I need to do?

It is a class 4 laser, which is very safe to use under international standards and FDA recommendations for protection. MOZLASER offers a wide range of laser protection gears for the protection of operator’s skin and eyewear.

3.Will fiber laser rust removal damage the metal substrate being cleaned?

The CW fiber laser’s spot is Gaussian and will damage the substrate by about 5 microns. The Pulse fiber laser is flat-topped and will not damage the substrate.

4. Does fiber laser rust removal machine can remove painting and oil pollution on the metal?

Yes,this kind of rust removal machine not only can remove rust,but also removal painting,dust,oil pollution,oxide layer,etc