MOZLASER Professional High Pressure Air Compressor for Laser Cutting Machine

- 1000W-40000W fiber laser cutting machine matches

- Sufficient pressure and flow to ensure cutting efficiency

- Oil-free and water-free design protects your laser cutting head

- There are more than 1000 clients using our air compressor

How to choose a best air compressor for laser cutting?

Compared to other ordinary machines and equipment, the most unique requirement of fiber laser cutting machines for air compressors is to be completely oil-free and water-free. This is because the high pressure air system of the laser cutting machine is connected to the laser cutting head for cutting stainless steel, carbon steel and aluminum for auxiliary cutting.

If the compressed air contains water or oil, it can pollute not only the pipeline, but even the lenses and sensors inside the laser head.This can cause damage to the laser head when you turn on the fiber laser cutting machine.

So the three main points of selection when choosing a high pressure air compressor are flows:

1. The maximum air pressure of the compressor needs to reach 1.6Mpa

2. The flow rate needs to meet the requirements of the laser machine power (contact us to inform your laser power)

3. The air compressor’s efficiency and effectiveness of oil and water filtration

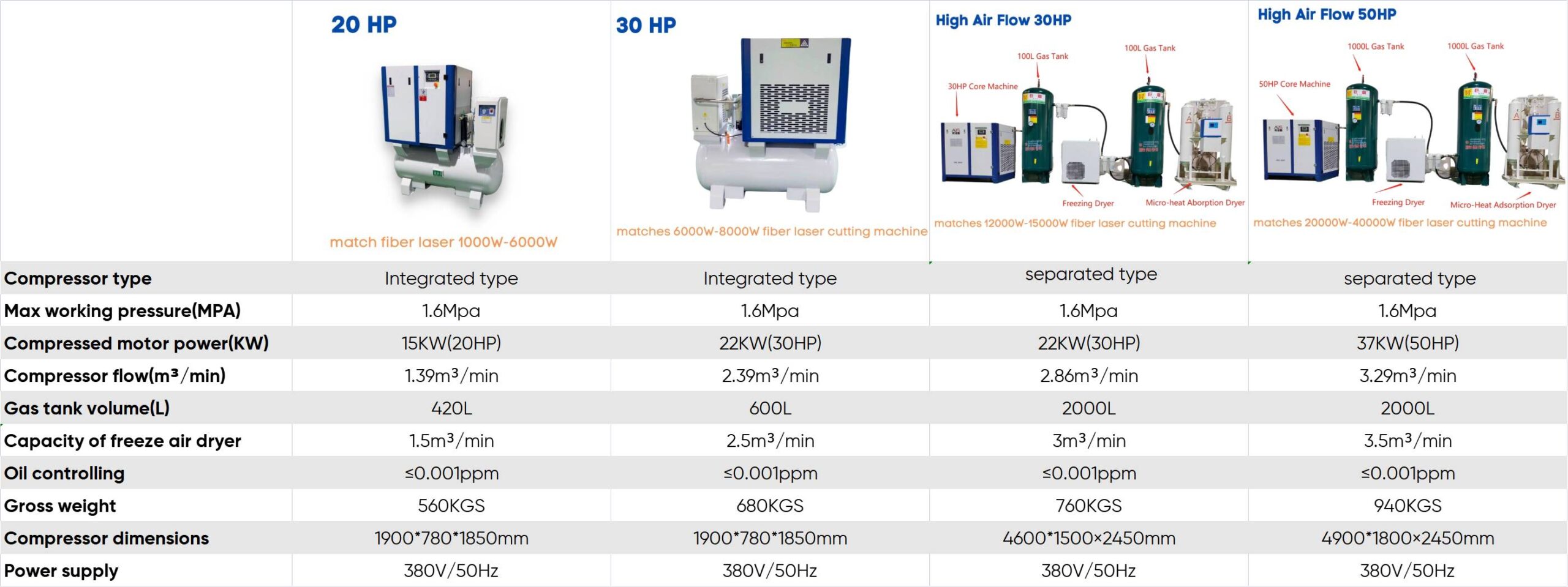

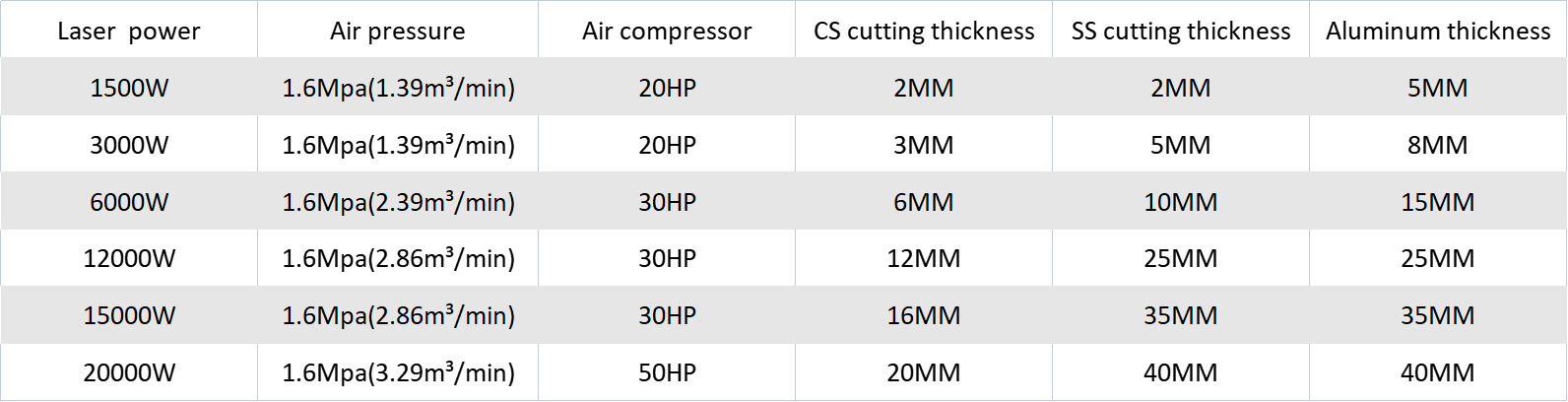

Technical data of the ARS series air compressor.

- Table

Core Components of the Air Compressor

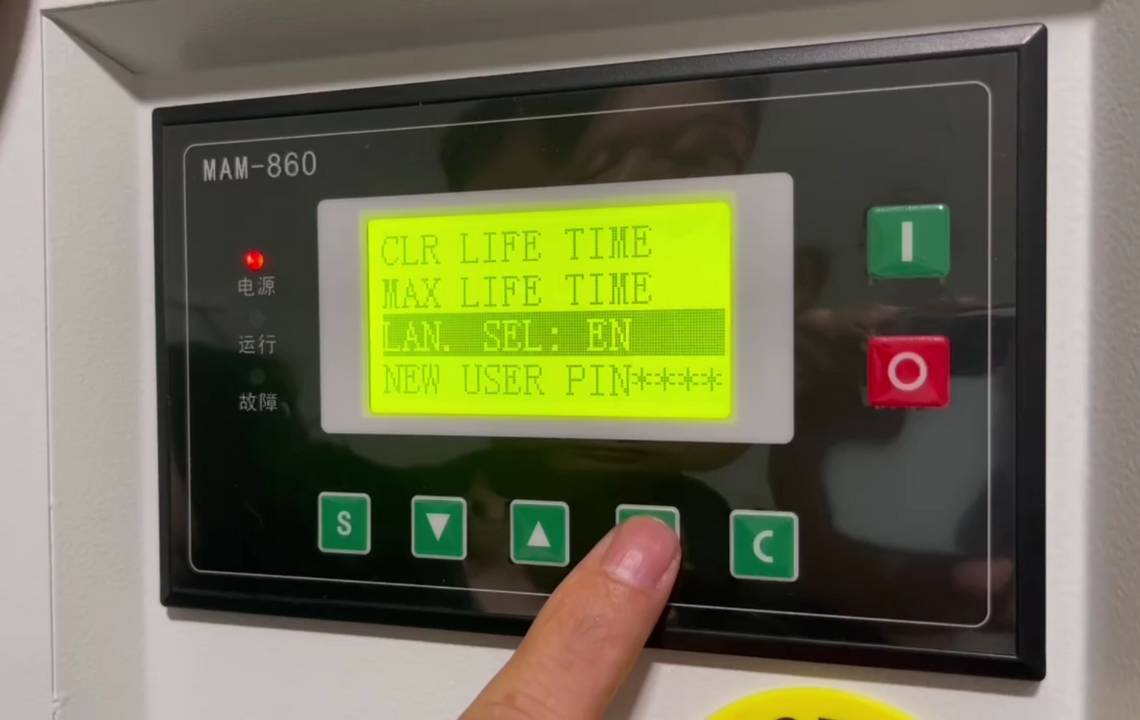

Smart Control System

Intelligent control panel, connected to high pressure sensors, for real-time monitoring of air compressor flow and pressure.

Smart management logic, automatic monitoring of compressor temperature,engine oil status, etc. And remind users to follow regular maintenance.

Screw Compressor Engine

MOZLASER air compressor for laser cutting machine adopts the international famous brand BCS or Hanbell screw compressor engine, which is stable and reliable and needs no special maintenance.

Compressor engine runs on 8 bearings and compresses air fast. It can ensure the stability of air pressure and flow rate during laser cutting process.

Compressor Gas Tank

Air compressor for laser cutting machine use a gas storage tank with a wall thickness of more than 6 mm to ensure the pressure and flow of gas. Each tank is pressure tested for explosion protection and has a separate test certificate.

High Capacity of Freezing Dryer

One of the core standards of the best air compressor for laser cutting is water free. The refrigeration drying speed and flow rate of the freeze dryer must be higher than the standard flow rate of the air compressor.

Oil/Gas Separator

The use of a good oil gas separator can greatly reduce the oil content in compressed air, according to our testing data our high pressure compressors can make oil controlling standard to ≤0.001ppm.

5 Stages Impurities Filters

The high precision five-stage filters can effectively filter the impurities in the compressed air, and the precision of filtering particles is 0.01μm.

It provides your laser machine’s piping system and laser cutting head with pure and high quality compressed air, which also greatly reduces the possibility of being polluted and damaged.

Over 1000 customers are already using our compressors for their laser cutting machines.

- Customer Site

- More Cutomers

User manuals and maintenance guides for the laser cutting air compressors

More videos from our customer's air compressor use sites.

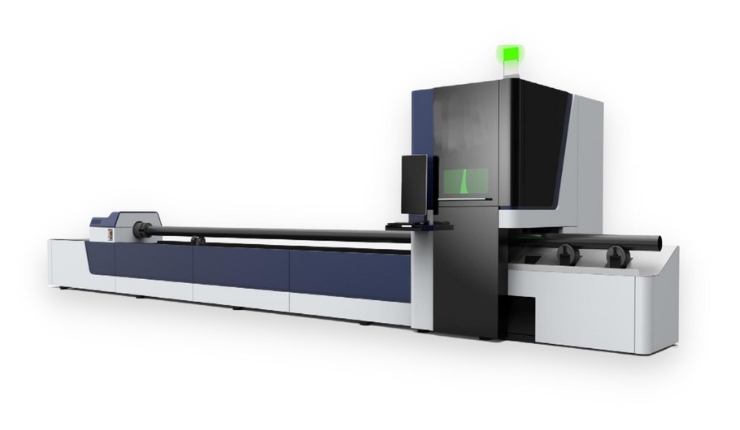

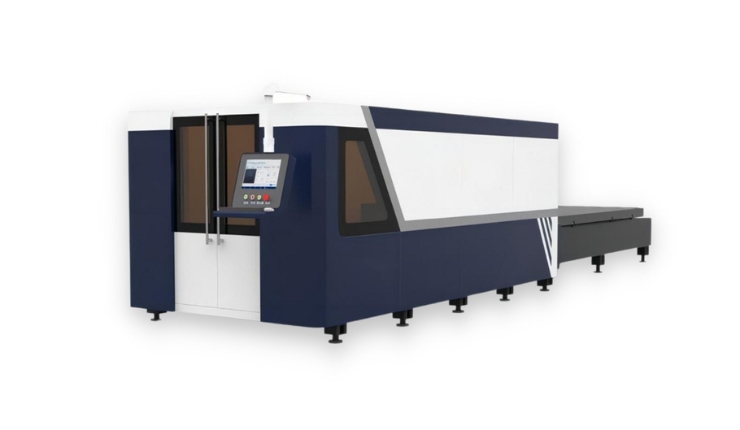

MOZLASER fiber laser cutting machines that can use air compressors. (4)

MOZLASER high-pressure air compressor adopts famous brand compressor engine, high-efficiency motor, customized stainless steel plate heat exchanger,freezing dryer and air storage tank, five-stage precision filter, high filtration precision, stable air supply, compressed air settling in the storage tank is more conducive to the discharge of water, low dew point of the freezing dryer. The whole perfect layout of the combination,all make this air compressor perfectly matched to laser cutting.

The biggest advantage of air cutting is the low cost,you can choose a high power laser machine to cut thin steel plates using high pressure air. The high pressure air compressor system is the best choice for high power laser cutting, both in basic cost and subsequent service costs, as well as in effectiveness and cutting speed, with at least 60% energy savings compared to using nitrogen and oxygen to cut.

Professional plywood package for international shipping