Mixed Laser Cleaning Machine Means Contiuous Fiber Laser Mix With Nanosecond Pulsed Fiber Laser

What is the Definition of Mixed Cleaning?

Mixed Cleaning Means in this Laser Cleaning Machine We Will Use Continuous Fiber Laser Source and Nanosecond Pulsed Laser Source Two Types of Laser Source. Now MOZLASER‘s Custom Mixed Cleaning Machine Power Pairing is 2000w Continuous + 300w Pulsed, 4000w Continuous + 500w Pulsed, 6000w Continuous + 1000w Pulsed, Two Laser Modes Work Together to Clean the Surface of the Material.

Laser Mixed Cleaning Technology is Not Only the Superposition of Two Type of Laser, the Focus is on the Utilization of Energy is Much Greater Than the Simple Addition of Two Heat Sources. in the Thicker Coating Material Laser Cleaning, Due to the Large Energy Output of a Single Laser Multi-pulse, High-power Pulsed Laser High Cost, Limiting the Laser Cleaning of Thick Coating Materials, and the Use of Pulsed Laser – Semiconductor Laser Composite Cleaning Can Quickly and Effectively Improve the Quality of Cleaning, and the Substrate is Not Easy to be Damaged. In the Aluminum Alloy and Other Highly Reflective Materials in the Laser Cleaning, a Single Laser Has a Large Reflectivity and Other Problems, and the Use of Pulsed Laser – Semiconductor Laser Composite Cleaning, Due to the Role of Semiconductor Laser Thermal Conductivity Transfer, Increasing the Energy Absorption Rate of the Metal Surface Oxide Layer, So That the Pulsed Laser Beam Can Be Faster to Strip the Oxide Layer, Thus More Effective in Improving the Removal Efficiency.

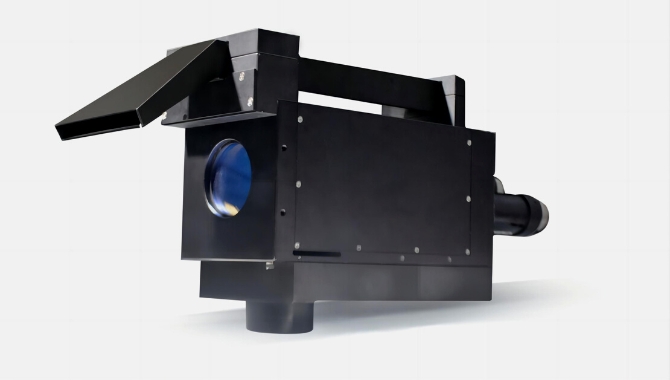

MOZLASER Mixed Laser Cleaning Head

At Present, the Laser Cleaning Gun on the Chinese Market is Generally Have Issues like Low Efficiency, Heat, Not Dustproof and Integration of Automation Difficulties,Cleaning Capacity is Limited. MOZLASER Has Made Improvements to These Problems and Developed a Strong Performance, The Largest Power Composite Cleaning Head Known in the Chinese Market Model Clean-Mix Laser Cleaning Head. The Maximum Can Match 6000w Continuous Laser + 1000w Nanosecond Pulsed Laser Power Combination. Mixed Laser Cleaning Machines in the Large Scale Rust Cleaning and Large Area Paint Removal Market Applications Have Very Good Prospects.

How is the Appearance, Size and Weight of the Mixed Laser Cleaning Machine?

The Mixed Laser Cleaning Machine is Our Latest Developed Product, And It is Also Highly Customized Product. Please Contact Our Team to Communicate Your Laser Cleaning Needs and Your Company Information, and We Will Give You Our Latest Project Solution Document Customzied Based on Your Real Requirement.

Why the Mixed Laser Cleaning Machine?

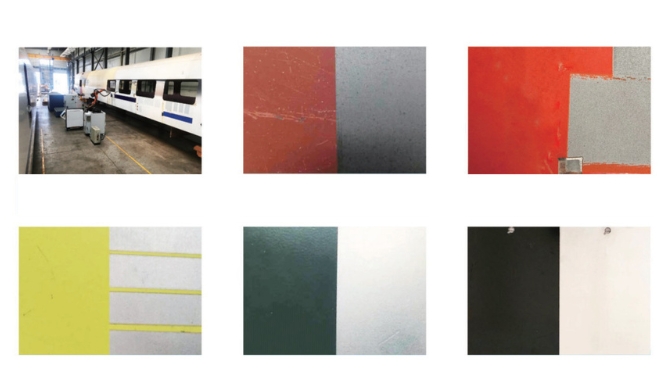

Nanosecond Pulse Laser Cleaning Technology Can Effectively Remove the Substrate Surface Paint Layer, but the Cleaning Efficiency is Low, Thick Coatings and Large Areas in Addition to Paint Cleaning Speed is Slow, the Limitations Are Great. The High Power Continuous Laser Cleaning Machine is Not Suitable for Thick Paint Cleaning and Large Scale Rust Cleaning, and Continuous Laser Cleaning Thermal Effect is Very Large, May Cause Deformation of the Substrate. High-power Composite Cleaning Technology is Another New Development Direction of Laser Cleaning, is Through the Nanosecond Pulse Laser and Continuous Laser Source’s Modulation Pulse Laser Interaction to Form an Enhanced Adaptive Cleaning Method, Laser Composite Cleaning Technology to Avoid the Shortcomings and Shortcomings of a Single Cleaning, with the Advantages of Improved Cleaning Quality, Increased Cleaning Efficiency, Stable Cleaning Process.

The Advantages of High Power Mixed Laser Cleaning Machine

A. High Cost Performance, Can Save Your Cost,

1. In the Real Test, the Efficiency of the Product is 700% of the Traditional Single 1000w Pulsed Laser Cleaning Machine, the Overall Cost Performance Improved by 2-3 Times.The Product Both Pulse Laser and Continuous Laser Cleaning Advantages. Removal Capacity, High Cleaning Efficiency, the Pollutants Can Be Cleaned Once Without Residue.

2. Wide Application, Suitable for Cleaning Strong Adhesion or Thick Layer of Pollutants, While Not Damaging the Substrate, the Cleaning Range for Customers is Extremely Wide, Especially for Large Machinery and Equipment or Aircraft Skin, Ship Rust,High-Speed Rail Way and Other Projects of Laser Cleaning Applications, a Further Improvement.

B. Security Upgrades, Fast Response, Ultra-long Life,

1. Equipped Insert Air Knives, Which Can Be Vacuumed and Dustproofed to Protect the Focusing Lens.

2. Excellent Heat Dissipation, Long Time Use Does Not Damage the Oscillator and Focusing Lens.

3. Installed Dust Suction Device, to Avoid Dust Pollution of the Environment and Equipment.

4. Stable Performance, Fast Response, Shock and Vibration Resistance, Long Life.