All Moz Laser's Products Through Strict Testing

Moz Laser equipment has strict testing and inspection processes in the design stage and production stage.

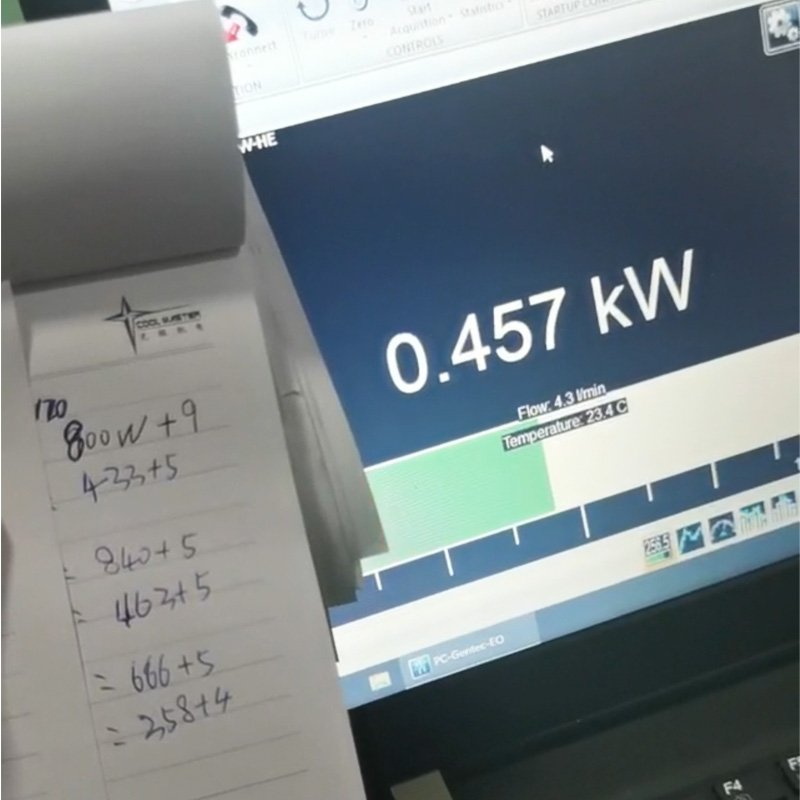

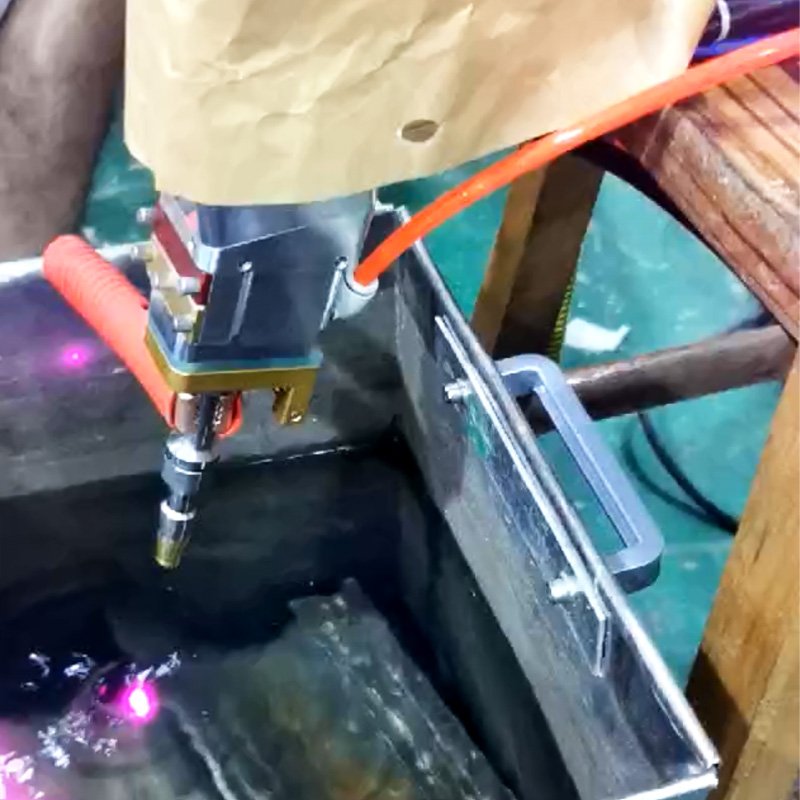

1. Continuously test the end laser power to monitor the laser transmission efficiency of the laser welding gun and continuously improve the laser welding gun structure.

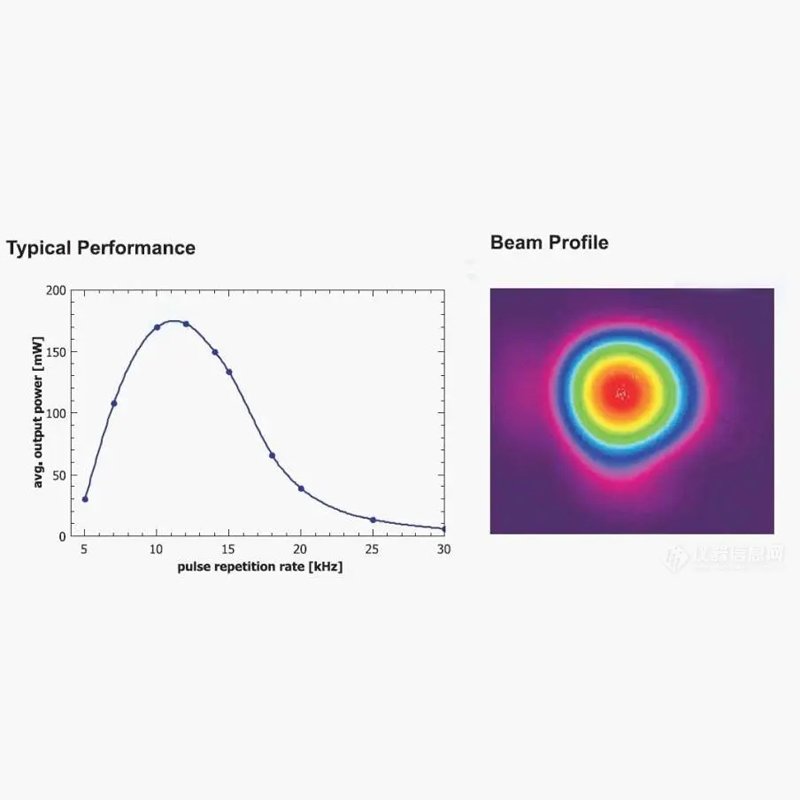

2. Monitor the laser source spot shape, peak power, and power fluctuation range using a laser spot monitoring instrument.

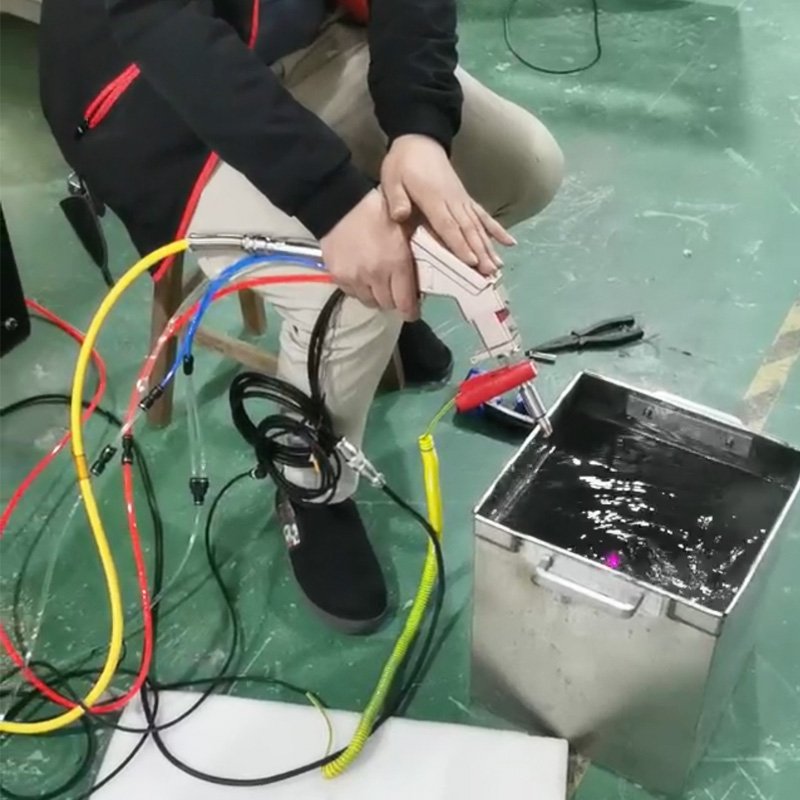

3. More than 24 hours of continuous laser beam working test, monitoring laser head temperature and laser source power fluctuations to ensure equipment stability.

QUALITY CONTROL AND TESTING

Test Laser Peak Power, Spot Shape and Laser Beam Output Stability

Observation of Laser Spot Shape of the Laser Source and Laser Power Stability

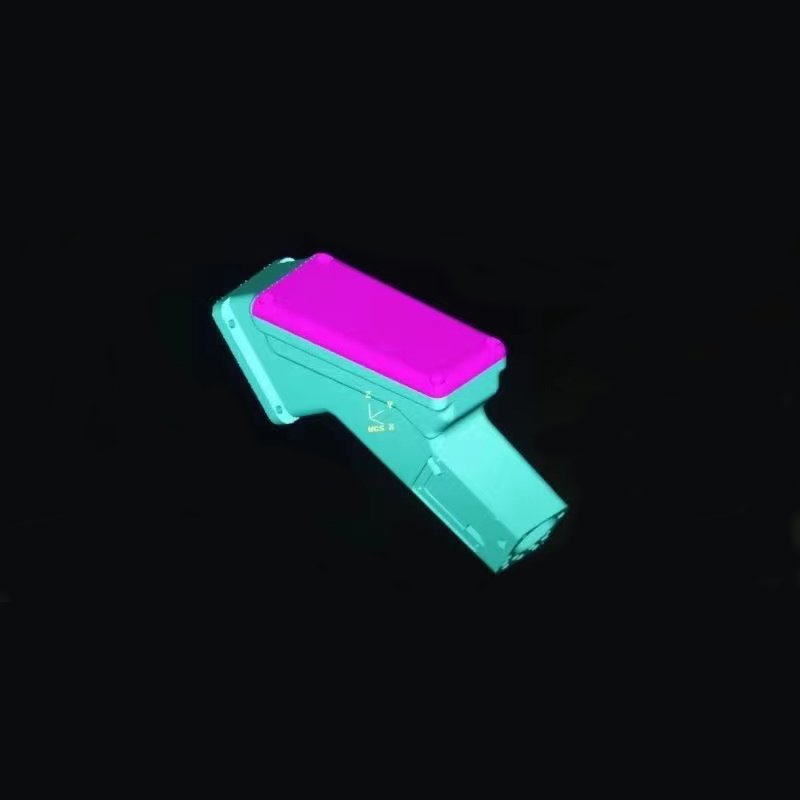

High Precision CNC Center Machining the Laser Head Aluminum Parts

Before Shipment, All equipments for at Least 8 Hours Continuous Laser Beam Output

At Least 24 Hours Continuous Laser Beam Output Test for Laser Head Cooling Module

Laser Control System and Laser Head with Continuous Laser Beam Output for 24 Hours