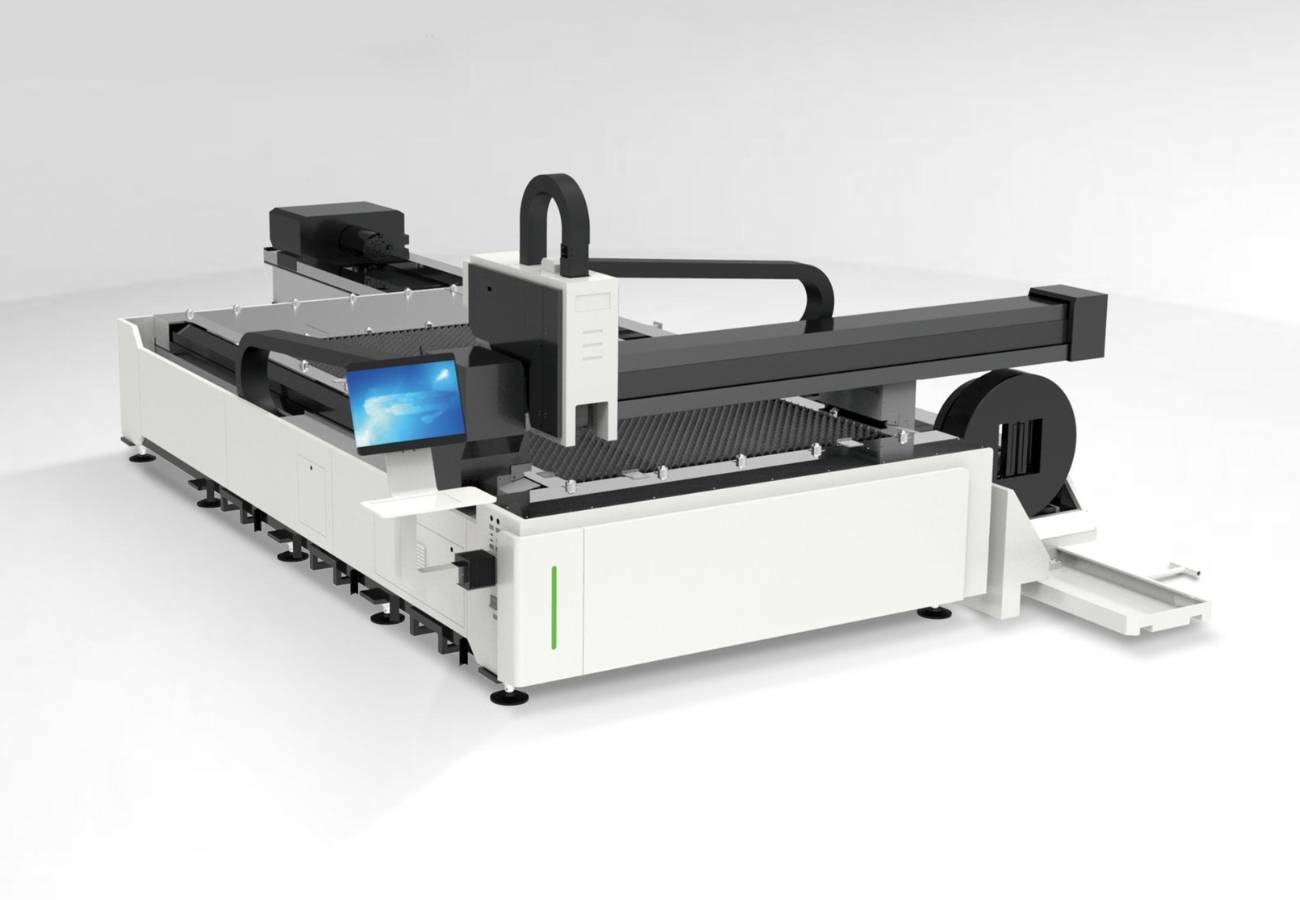

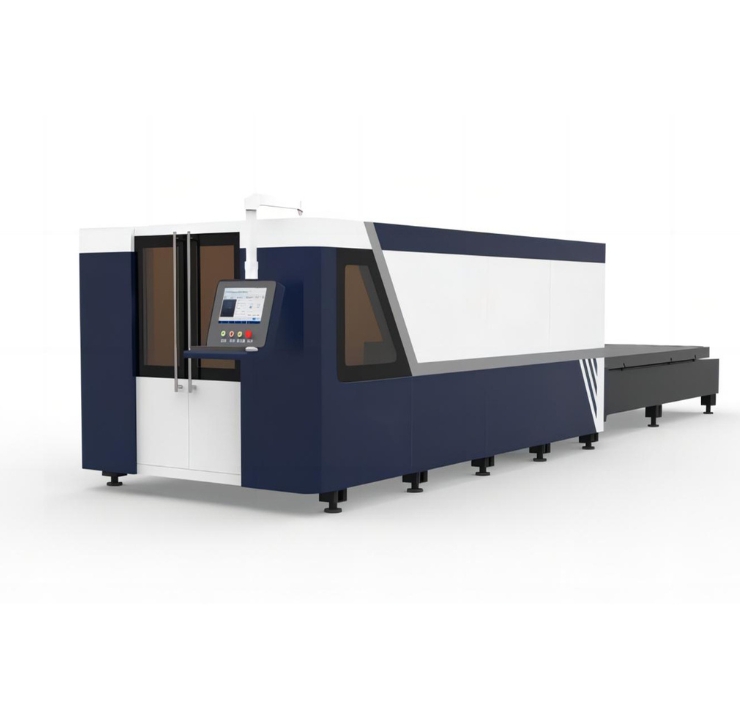

MOZLASER FR Series Sheet and Tube Laser Cutting Machine Combo Laser Cutting Machine

Single Pallet Fiber Laser Cutting Machine Main Features:

- Free Switching,The laser cutting head and CNC contral system can be freely switched between metal sheet cutting and metal tube cutting modes.

- Investment and Factory Space Saving,If your factory requires both sheet metal and tube cutting, then this sheet and tube laser cutting machine is perfect for you. It can reduce both your upfront purchase cost and your factory space usage, compared to purchasing a sheet metal cutter and another tube laser cutter.

World Top1 or Top2 Brand of Laser Source

MOZLASER’S sheet and tube laser cutting machine uses the world’s TOP1 IPG fiber laser source or TOP2 Raycus fiber laser source to ensure the stability of the machine. According to our test data, the failure rate of IPG fiber laser is less than 5% in 3 years of use, which shows how stable the IPG laser is. Raycus three-year failure rate is close to 8%, this data compared to IPG is really not that good,but not bad too. And Raycus is becoming more and more popular with its very competitive price.

And both IPG and Raycus are miniaturizing the laser size in these years. Please compare the laser size of 3000W IPG 5 years ago and 3000W IPG now in the picture. The volume is more than 5 times smaller, more convenient to transport and have higher heat dissipation rate .

High Precision Machined Machine Frames

Sheet and tube laser cutting machine is a high precision metal processing equipment, the industry’s conventional requirements for cutting accuracy is ± 0.05mm. So if you can guarantee the cutting accuracy of the entire laser cutting machine?

The most basic thing is to ensure the accuracy of the mounting surface of the machine, MOZLASER’s machine base frame through two gantry milling process to ensure the level of the mounting surface of the guide and rack, with a high-precision rack and linear guide can effectively ensure the cutting accuracy of the laser cutting machine.

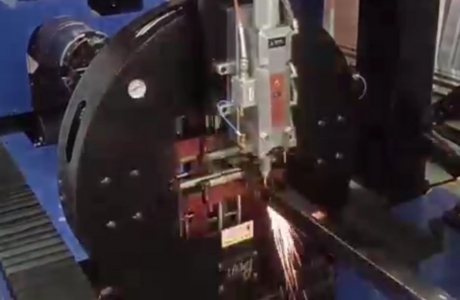

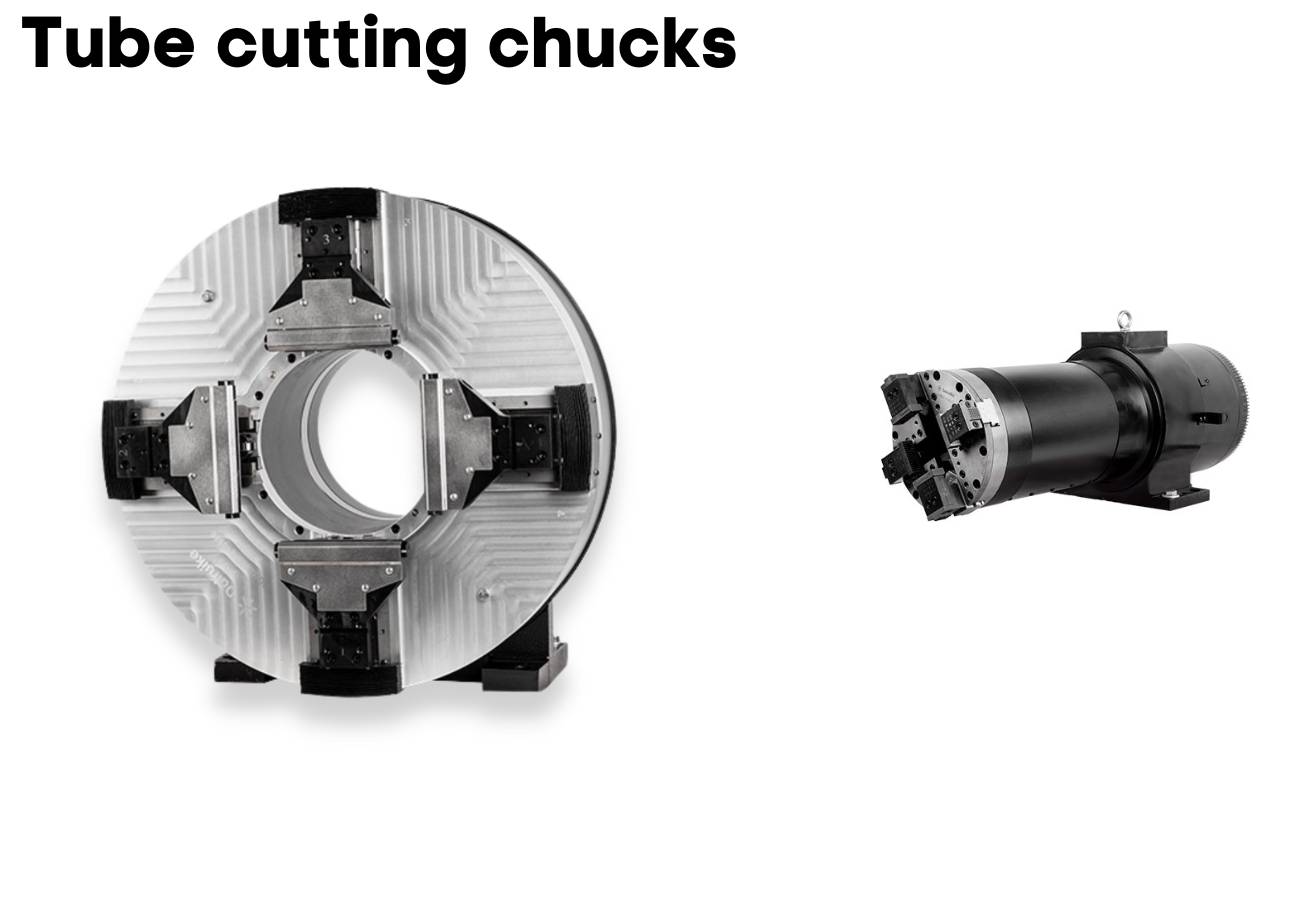

Customized Size Tube Cutting Chucks

Tube cutting part of the machine use China’s No.1 Brand DAIRUIKE pneumatic chucks, the chucks drive are very precise, the air resistance and friction is small for reasonable movement and rotation of the dual chucks, the full stroke of stable clamping tube without loosening.

Pipe Laser cutter adopts pneumatic chuck, compared with electric chuck pneumatic chuck is more stable, because its operation is mainly through physical pneumatic operation, the probability of error is low. While the electric chuck has a complicated electrical circuit structure, after our test the probability of error is greatly increased.

FSCUT 3000 Pipe Laser Cutter and Sheet Laser Cutter Controller System

FSCUT 3000 is a CNC laser control system developed by SHANGHAI FRIENDESS ELECTRONICS TECHNOLOGY CO., LTD for sheet and tube combo laser cutting machine. The system integrates two control interfaces laser tube cutting and laser plate cutting, which can be freely switched to achieve the application of both tube laser cutting mode and plate laser cutter in the same laser cutting machine.

And the system can also control the laser head to switch between left and right movement to handle the applications of pipe laser cutting and sheet laser cutting. In addition, it can also control the table exchange of dual pallets laser cutting machines.

Focal Length Adaptive Laser Cutting Head

Raytools autofocus series laser head is matched with different laser cutting head system for different laser power from 1000W-6000W. The laser head will automatically adapt to the cutting height and cutting focal length of z-axis by setting the thickness of the material to be cut through the laser cutting main board and cutting software. No manual adjustment is required, saving manpower and reducing the possibility of cutting errors due to incorrect focal length.

Multiple laser protection mirrors are designed to effectively seal the collimating and focusing lenses of the laser head to prevent dust and other debris from contaminating the inside of the laser head and causing damage to the laser head.

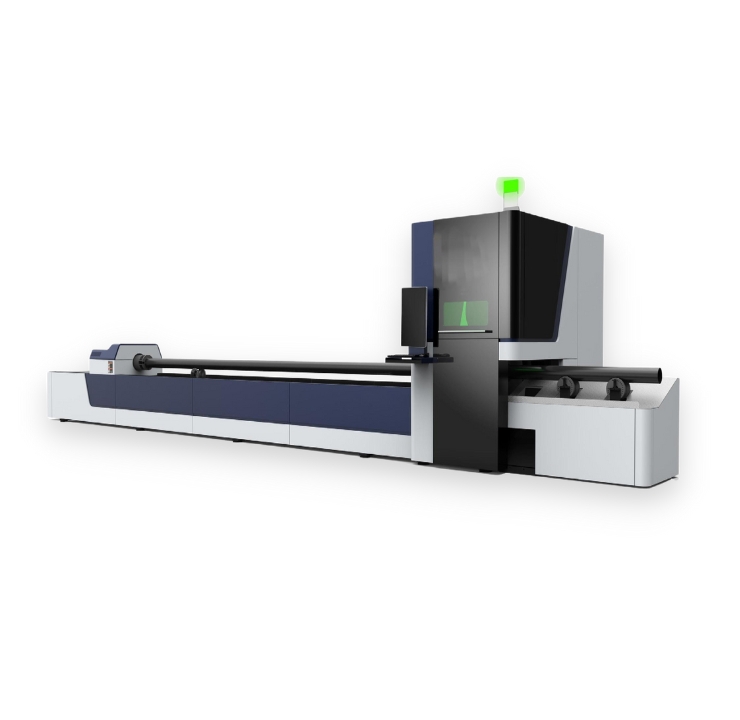

One-Click Automatic Alignment of Tube Edges

Automatic alignment of one end of the metal pipe is controlled by the cutting head and cutting control system, reducing the waste caused by manual alignment. And it only requires one click inside the laser software to align automatically with a waste material length of 0.

The system and the laser head also have their own deflection correction function, which automatically identifies the axis distance of the pipe and the focal distance of the laser head from the pipe surface.

- Data Sheet

- Package Components Details

- Warranty and Service

Sheet and Tube Laser Cutting Machine

| Machine Model | MZ-1530FR | MZ-1540FR | MZ-1560FR | MZ-2040FR | MZ-2060FR |

| Working Area | 1500×3000mm | 1500×4000mm | 1500×6000mm | 2000×4000mm | 2000×6000mm |

| 3000mm/6000mm Tube Cutting length and 120mm/160mm/220mm Diameter Tube Chuck Options | |||||

| Laser Power Options | 1KW/1.5KW/2KW/3KW/4KW/6KW | ||||

| Max Running Speed | 60m/min | ||||

| Max Acceleration | 1.0g | ||||

| X/Y Axis Positioning Accuracy | ±0.05mm | ||||

| Repeated Positioning Accuracy | ±0.01mm | ||||

| Machine Voltage | Ac 380V 50Hz | ||||

| Cooling Way | Water Cooling(Industrial Water Chiller) | ||||

| Machine Max Load Weight | 0.75T | 1T | 1.3T | 1.5T | 2T |

| PARAMETERS ARE FOR REFERENCE ONLY, CUSTOMIZATION SERVICE IS AVAILABLE | |||||

2 year warranty for whole machine except consumables.

MOZLASER “FR” series sheet and tube laser cutting machines

This combination laser cutting machine can cut sheet metal and metal pipe at the same time, it has the advantage of more wide range of applications, more economical than buying two laser cutting machines for both sheet metal cutting and metal tube laser cutting. Combo laser cutting machine covers a smaller landing area save your factory space, the price is also more cost-effective.

Sheet and tube laser cutting machine, also known as combo fiber laser cutting machine, can cut both metal plates and metal tubes. In the metal fabrication industry, plate and tube laser cutting machines are becoming more and more widely used. Many metal fabricators and other metal product manufacturers such as furniture manufacturers, structural steel fabricators, etc. have the need to process both sheet metal and metal pipe, so the integrated plate and tube laser cutting machine is naturally the first choice. It can not only meet the customer’s processing needs, but also can be a good way to save equipment purchase costs, a multi-purpose machine, why not do it?

Metal plates and tubes are widely used in various industries, everywhere. For example, cars and boats, furniture, fitness equipment, agricultural machinery and other industries. Plate and tube integrated fiber laser cutting machine to meet the dual needs of fiber laser cutting machine manufacturers cutting plate and tube, with its intelligent and efficient, intensive design, lower investment and higher output characteristics to become the choice of many metal fabricators.