In recent years, with the improvement of environmental protection requirements and people’s awareness of environmental protection, this environmental protection requirements and awareness to the worldwide cleaning industry has brought new opportunities for development, a variety of cleaning technologies conducive to environmental protection come into being, and laser cleaning technology is one of them. Compared with traditional mechanical cleaning, chemical corrosion cleaning, high-frequency ultrasonic cleaning, and other traditional cleaning methods, laser cleaning has the advantages of high efficiency, fast, low cost, small thermal and mechanical load on the workpiece, non-contact non-damage, and laser cleaning waste can be recycled to protect the environment and operator health and safety. Laser cleaning can remove a variety of different thicknesses, and different compositions of the coating, and can even clean the traditional cleaning methods can not solve the problem. In addition, the laser cleaning process is easy to achieve with automatic control and remote control.

Laser cleaning in many industrial and mechanical fields have a very good application, one of the very important fields is the rail transportation industry, laser cleaning train track is gradually replacing traditional cleaning methods. MOZLASER through the different power of the laser cleaning machines test data to show you the advantages of laser cleaning in cleaning train track applications.

Train tracks due to years of exposure to the air, coupled with the wind, rain, snow and cold frost, the surface is easy to rust. In order not to affect the safe operation of the train, cleaning train track is very necessary. In our test case, we tested and evaluated the effectiveness and efficiency of cleaning railroad tracks using two different laser power fiber laser sources, mainly for rust cleaning, and recorded the cleaning results.

(1) Cleaning System Configurations

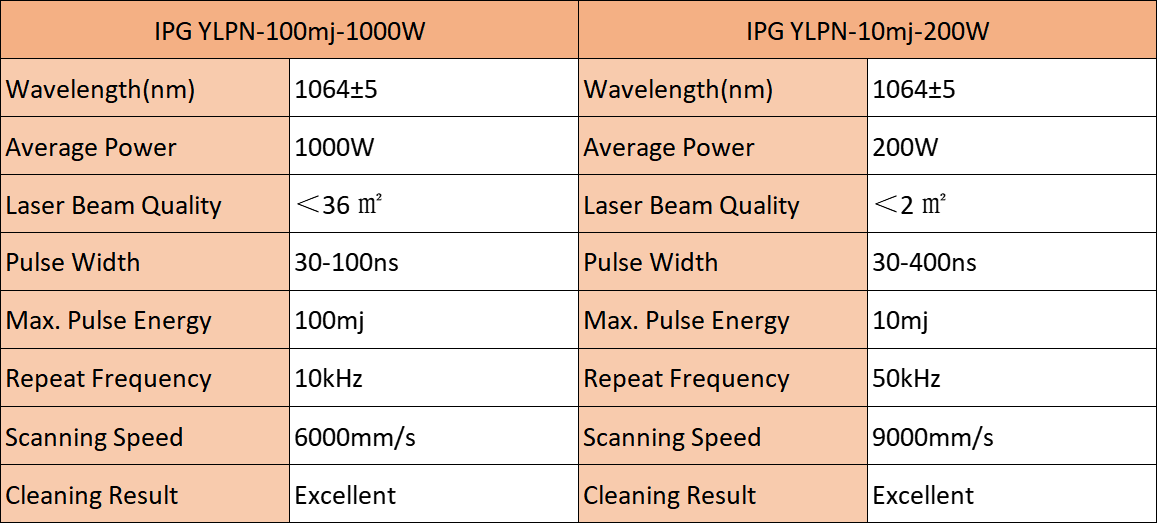

The specific system configurations for this cleaning railroad tracks test is shown in Table 1.

The experiment will test and evaluate IPG’s laser YLPN-100-30*100-10-1000W and YLPN-10-30*400 -20-200W, two nanosecond pulsed fiber laser powers, will be tested and evaluated for cleaning the rust layer of train tracks. Both lasers work in pulse mode and are equipped with MOZLASER scanning oscilloscope laser cleaning guns, in different scanning methods and process parameters. MOZLASER laser cleaning machine can also be equipped with CNC platform or robot, to achieve different surface cleaning requirements to meet. The specific physical diagram of the experimental system is shown in Figure 1.

Figure 1/Table 1: Scanning laser cleaning gun/ Pulsed laser Source details

The rust layer on the surface of the rail, in fact, contains two layers, one is the oxide skin surface layer of iron trioxide (Fe2O3) yellow floating rust layer, and the other is a deeper layer of black rust layer, the physical as shown in Figure 2.

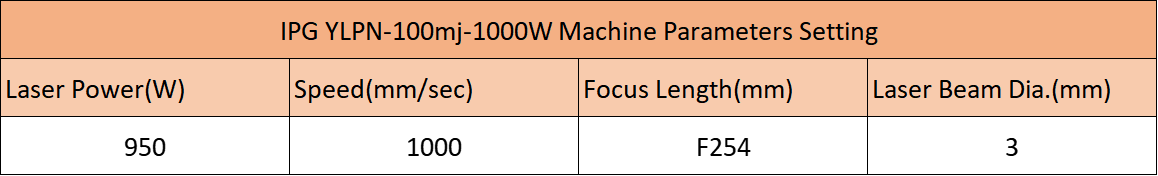

Figure 2 /Table 2: Using YLPN-10-30*400-20-200W power laser cleaning machine, Rail oxide surface layer of iron trioxide (Fe2O3) yellow rust layer and a deeper layer of black rust layer (right)/ 1000W machine setting parameter

(2) Cleaning Railroad Tracks Parameters Setting and Cleaning Result

First of all, the YLPN-100-30*100-10-1000W laser was used for cleaning Tests. The specific cleaning parameters selected for the experiment were configured as shown in Table 2.

Figure 2: Using YLPN-100-30*100-10-1000W laser cleaning machine only cleaned off the yellow rust layer on the rail surface, while the deeper black rust layer still existed. In optimizing the focused spot at 0.8mm, a very good cleaning effect can be achieved.

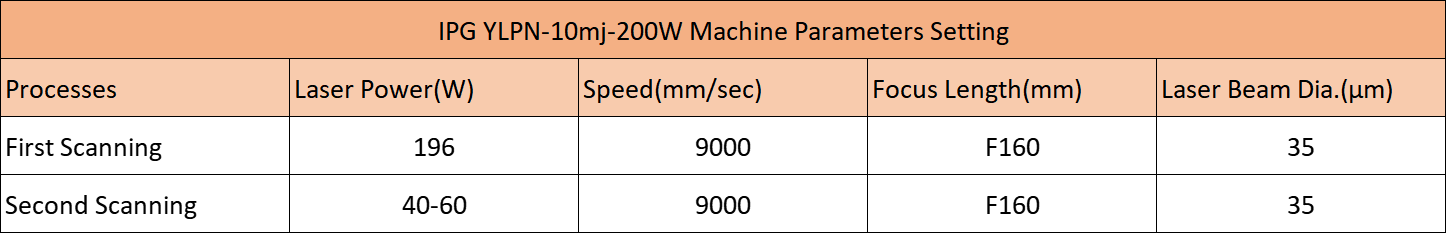

Next, we used YLPN-10-30*400-20-200W laser cleaning machine to make a test of cleaning train track. In order to get better cleaning effect, the cleaning with YLPN-10-30*400-20-200W laser Cleaning machine is divided into two steps, the difference between these two steps is mainly the different laser power used, the first step is slightly more powerful, for The power of the first step is slightly higher for cleaning the rust layer in a large area; The power of the second step is reduced for more precise and fine rust layer removal. The specific parameter configuration is shown in Table 3.

The experimental results show that after two steps of cleaning with high power and low power, the yellow rust layer and black rust layer on the rail surface are completely cleaned off, and the cleaned rail is white and bright, as shown in Figure 3.

Figure 3 /Table3: Using YLPN-10-30*400-20-200W power laser cleaning machine, the yellow rust layer and black rust layer on the surface of the rail are completely cleaned off, and the cleaning effect of the base material body color is obtained/ 200W machine setting parameter

From the results of the cleaning train track experiment, we can easily see that the YLPN-100-30*100-10-1000W laser is very effective in cleaning the Fe2O3 yellow rust layer on the shallow surface of the rail, which is more effective than using the YLPN -10-30*400-20-200W laser cleaner has a higher efficiency. For cleaning the deeper black rust layer, YLPN-10-30*400-20-200W laser cleaner is a good choice.

Comprehensive cleaning efficiency, cleaning effect and other considerations, in order to achieve high efficiency, high quality rust layer cleaning effect, choose the laser cleaning machine for cleaning railroad tracks,MOZLASER suggests that two lasers can be used in combination: first use the large spot, low power density of YLPN-100-30 * 100 -10-1000W laser cleaner to efficiently remove the Fe2O3 yellow rust layer on the surface of the rail; then use the small spot, high power density YLPN-10-30*400-20 -200W cleaner to remove the deeper black rust layer