The Importance of Cleaning the Industrial Mold

The Mold Shapes the Appearance of the Product, and Also is One of the Key Factors to Ensure the Inner Quality of the Finished Product.

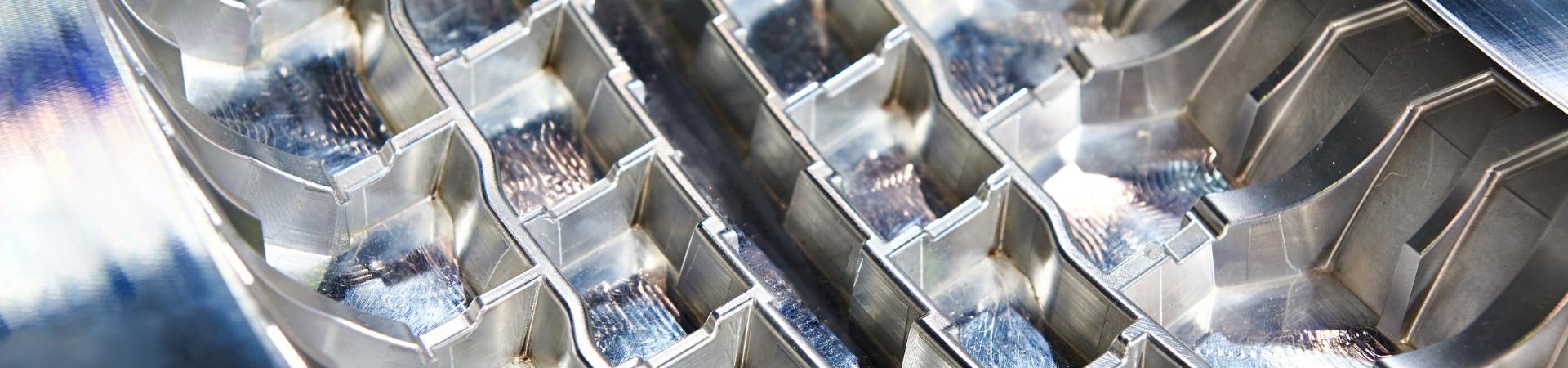

Inevitably, the Molds Will Generate Dirt and Oil Layer on the Working Surface During Long Time Use, Which Will Affect the Appearance of the Products and the Accuracy of the Outer Edge Dimensions. in Order to Ensure the Production Quality of the Products, It is Necessary to Maintain the Moulds on a Regular Basis. Mold Cleaning is the Key Process in Mold Maintenance, Which Directly Affects the Whole Production Process of Tooling, and Incomplete Cleaning of Residual Substances Will Directly Affect the Quality of Products. Mold Cleaning Laser Machine Can Finish the Mold Cleaning Efficiently Without Damaging the Mold Base Material.

Some Advantages of the Mold Cleaning Laser

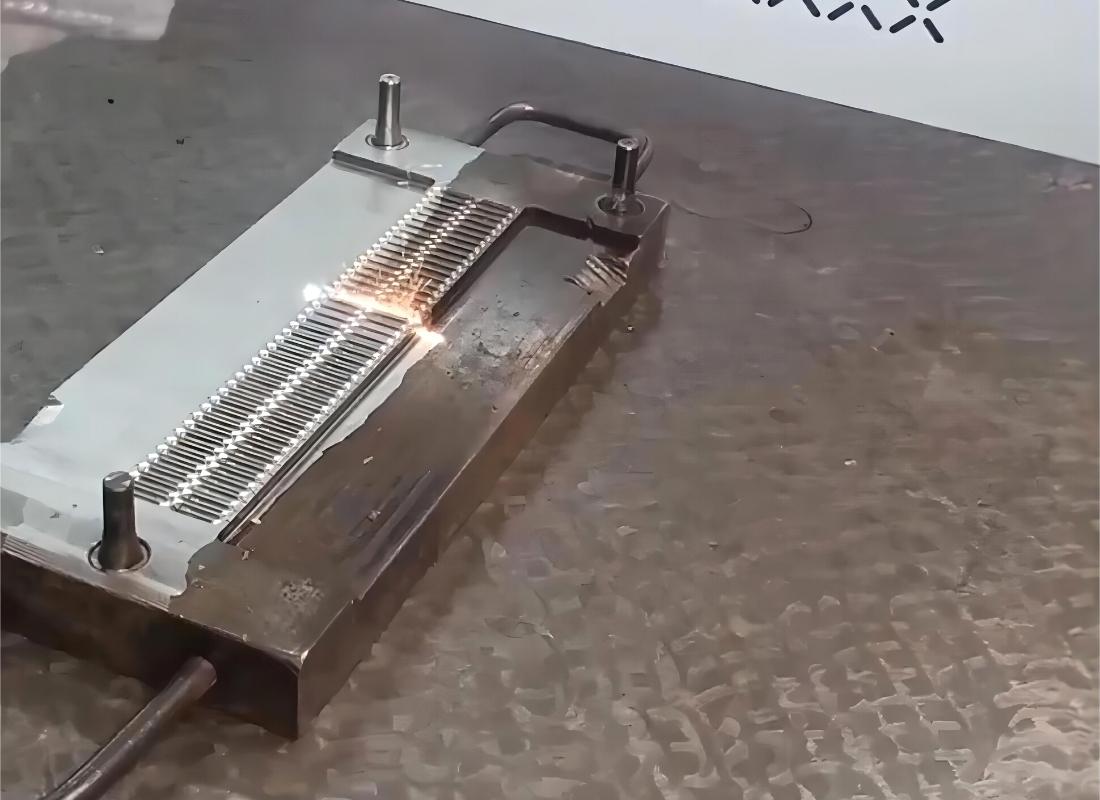

- Laser Cleaning is an All-round Cleaning Method. Through High Energy Laser Particle Scanning Irradiation Workpiece Surface, the Surface is Different from the Substrate Covering Layer Will Be Instantly Vaporized and Stripped. Laser Cleaning Machine Can Not Only Be Used to Remove Rust,Oil Film Layer,and the Oxide Layer, but Also to Remove Glue,Paint,Dirt,Coating layer,and to Dust Slag layer, Etc.. The Main Object of Mold Cleaning Laser is Mold Dirt (i.e. Solid Residue Attached to the Surface of the Mold Cavity), Rust, Oxidation Layer, Etc. The Laser Cleaning Machine Can Solve All the Mold Cleaning Problems.

- MOZLASER Laser Cleaning Machine Uses Nanosecond Pulse Fiber Laser Source, with High Peak Energy, Instantaneous Laser Scanning and Will Not Make the Mold Metal Surface Heating Up to Damage the Substrate. Only the Surface Contamination Layer Will Be Removed, after the Completion of the Cleaning Task, will Not Affect the Accuracy of the Mold.

- Laser Cleaning Machine is a Green Cleaning Method, a Non-contact Cleaning, No Cleaning Solution or Other Chemical Solutions, No Cleaning Waste Solution. Laser Cleaning Process Produces Pollutant Particles and Gas Can Be Simply Through the Portable Extractor Fan for Waste Collection and Purification Treatment, to Avoid Causing Environmental Pollution. It Also Avoids Improper Cleaning Operation, Causing Secondary Contamination of the Mold.

- Mold Cleaning Laser Operation is Friendly, and Low Running Costs. Laser Cleaning Machine Operation is Very Simple, Does Not Require Special Learning Laser and Mechanical Expertise, and Complex Use of the Process. A Newly Employed Worker Can Operate It After a Simple Training. The Pulsed Laser Source Used in Laser Cleaning Machine Has a Long Service Life ( Usually Up to 100,000 Hours), Requires No Maintenance, and Can Be Used for a Long Time with Stable Quality and Reliability. Later, Only Needs Regular Cleaning, Replacing the Dirty Lenses, No Special Maintenance Required.

Main Features of the Mold Cleaning Laser

- Pulsed Laser Power 50W-1000W Optional

- Portable Backpack Type Available with Battery

- Automatic Cleaning and Munual Cleaning Mode

- No Damage to the Mold Substrate, Saving Your Time and Effort

- Laser Source Maintenance-free, Convenient and Energy-efficient.

Different Pulsed Laser Power Machines for Your Choice (6)

Traditional Mold Cleaning Method Compared to Laser Cleaning Method

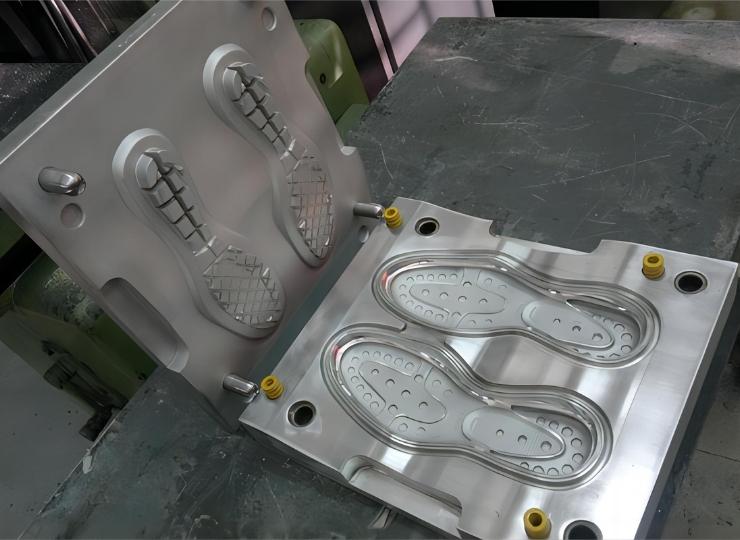

Laser Cleaning Technology in the Future Will Become the Mainstream of Various Mold Cleaning Methods, a Wide Range of Fields Such As Rubber Molds, Injection Molds, Die-casting Molds, Blister Molds, Etc.

The TraditionalCleaning Method Using High-pressure Water Cleaning, Dry Ice Cleaning, Brushing with Steel Wire Balls, Etc.. Such Cleaning Methods Exist Labor-intensive, Low Power, Low Safety Factor, High Cost and Other Problems. Mold Cleaning Laser Machine Speed is Very Good to Deal with This Problem.

Compared with Traditional Methods, Mold Cleaning Laser Has the Advantages of Environmental Protection, Non-contact, Precise Positioning, No Abrasive, No Thermal Effect, and Applicable to a Variety of Materials. for Precision Workpiece or Its Fine Parts Cleaning is Very Safe, Can Remove the Workpiece Surface Adhering Submicron Pollution Particles. Laser Cleaning Solves the Problem That Traditional Cleaning Methods Can Damage the Accuracy of the Mold, So Laser Cleaning Has Unique Advantages in Industry.

The Advantages of Laser Cleaning in the Mold Industry Have Been Highlighted and Are Rapidly Replacing Traditional Dry Ice Cleaning, Chemical Cleaning, and Manual Cleaning by Workers, and the Biggest Advantage is That It Will Not Damage the Mold and Will Not Destroy the Accuracy of the Mold.

MOZLASER Has Been Committed to Laser Welding and Laser Cleaning for Various Industry Applications and Has Been Working with Many Well-known Injection Molding Factories, and Tire Manufacturing Companies to Continuously Develop and Improve Laser Welding Repair and Laser Mold Cleaning Related Equipment.

Electricity Consuption.

Protective Windows of the Laser Head

Theoretically, This Laser Cleaning System is Maintenance-free for Life.

Only the Protective Lens and Cooling Water Need to Be Replaced Regularly.

Please Tell Us What Type of Molds to Be Cleaned and the Amount of Work Per Day, then Our Professional Team Will Advise.

We Can Understand Your Concern.

In the Past, German Laser Equipment Was the World Leader, but I Have to Say That Chinese Equipment Now Has Almost the Same Quality As German Equipment.

Because Our Machines Have Been Tested in the Market for a Long Time, This is the Real Source of Our Confidence.

And We Offer a Warranty of Up to 2 Years.