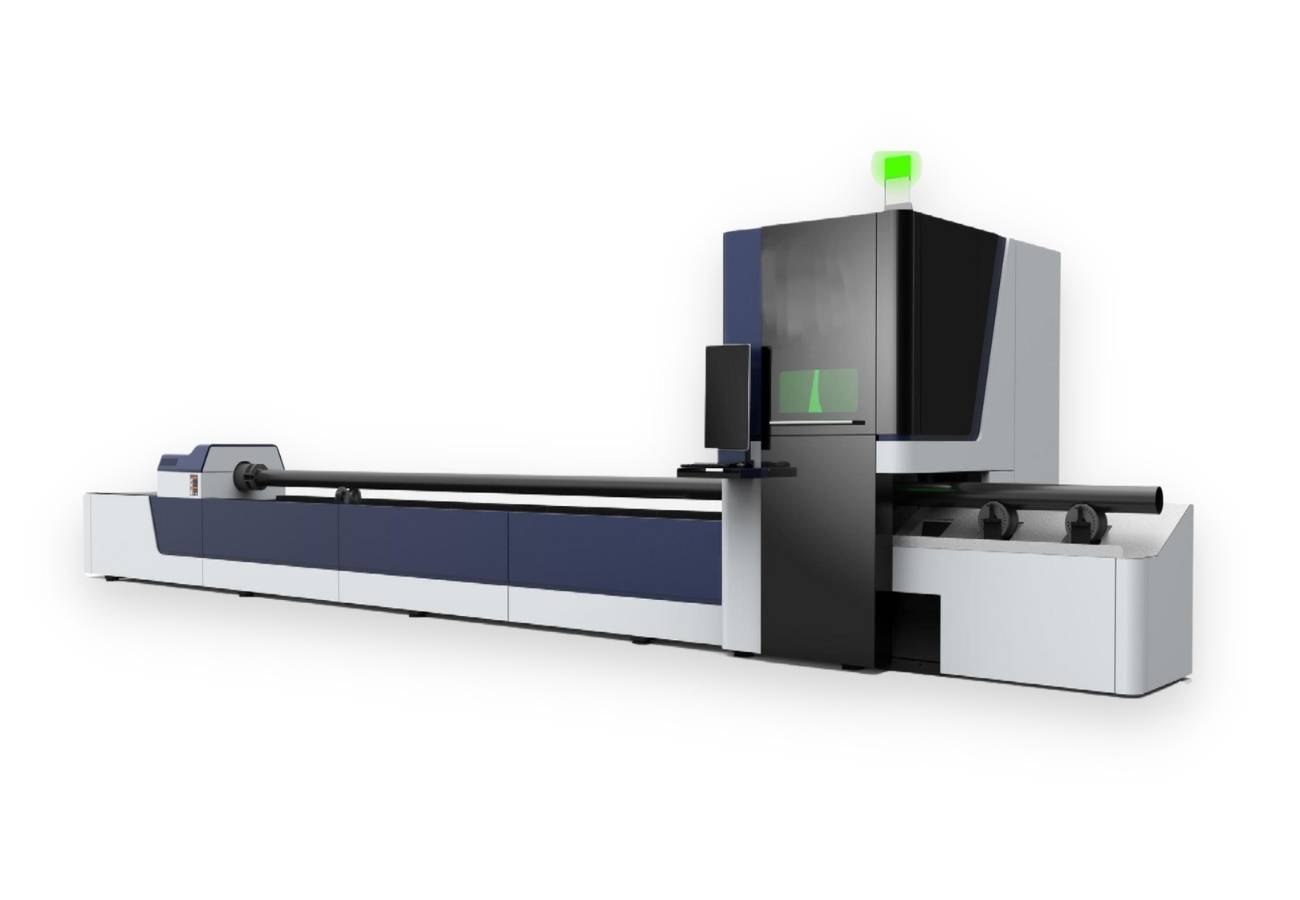

MOZLASER "TS" Series Laser Tube Cutting Machines Pipe Laser Cutter

Laser Tube Cutting Machine Main Features:

- Dual Chucks,It uses a double pneumatic chuck design with two chucks at the front and end to clamp the metal pipe.

- Highly Adaptable,Different diameters of pneumatic chucks options. If you want to cut small tubes you can choose 120mm chucks for greater cutting accuracy.

- High Speed,The MOZLASER pipe laser cutters use high speed pneumatic chucks with a rated speed of 150 rpm or more. The cutting speed of the laser tube cutting machine is guaranteed.

World Top Brand Fiber Laser Source

MOZLASER recommends the use of the world’s top fiber laser brand IPG Photonics, in the previous year IPG Laser launched a new generation of YLR-U series ultra-thin fiber laser sources maximum laser power of 6000W, it is small enough to be integrated directly into the laser machine, further optimizing the pipe laser cutter’s landing space.

The YLR-U series of lasers incorporates the advantages of IPG technology and is one of the few high-power lasers on the market with a gas-tight structure that can operate in harsh environments with relative humidity up to 90% and temperature up to 40 ℃ (104 ℉ ). In addition, the laser’s Web connectivity allows remote control and intelligent monitoring, and built-in diagnostic aids bring superior productivity and low overall operating costs and failure rates to key material processing applications such as welding and cutting.

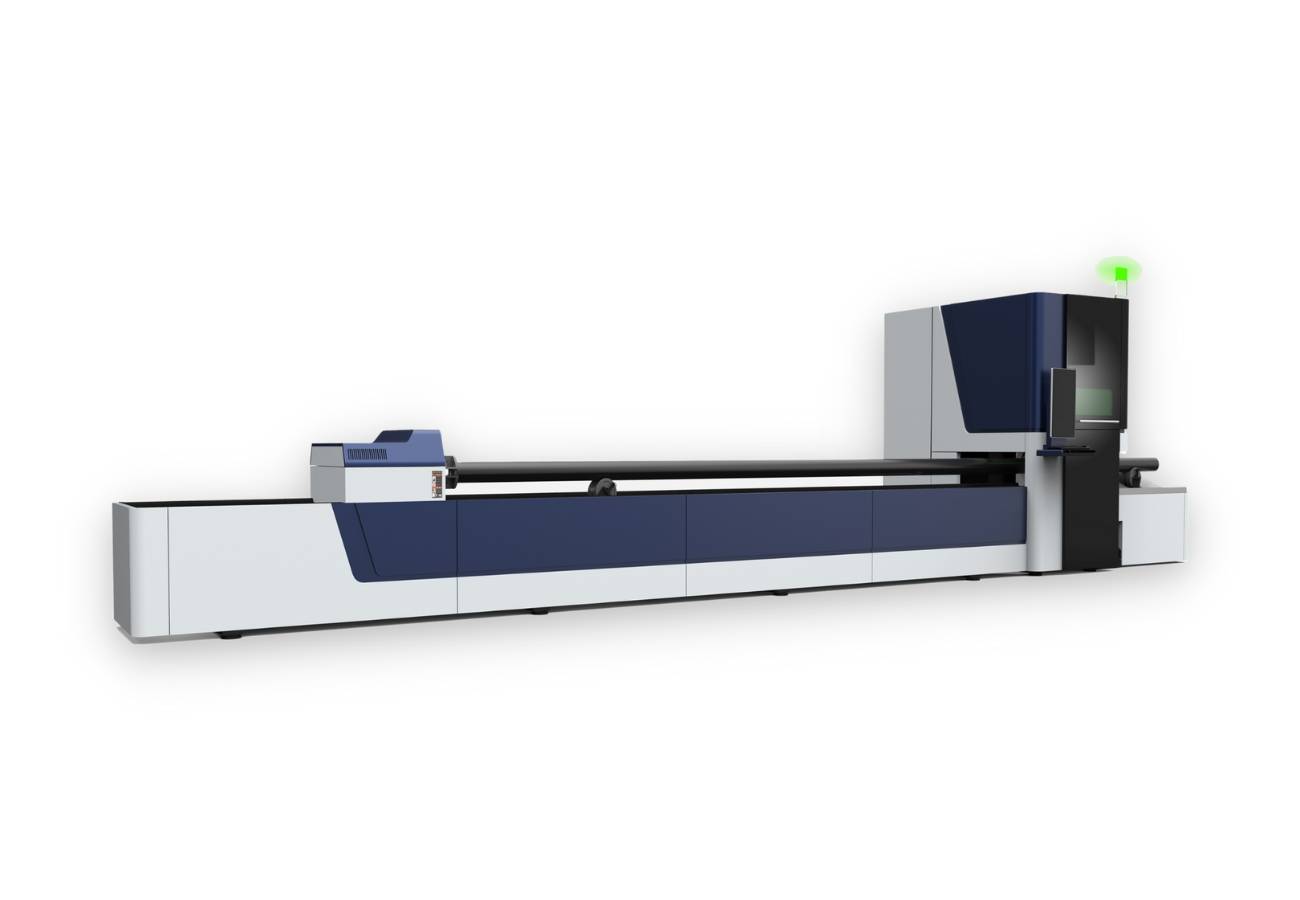

Steel Plate Welded Machine Base Frame

The pipe Laser cutter’s machine base frame adopts thick steel plate welded. The machine base frame is strong and durable and will not deform for 20 years.

The accuracy of the Laser tube cutting machine depends mainly on the accuracy of the Z-axis surface of the chuck mounting and the mounting surface of the back chuck guide. After two gantry milling processes, the cutting accuracy and repeat positioning accuracy of the machine can reach ±0.05mm.

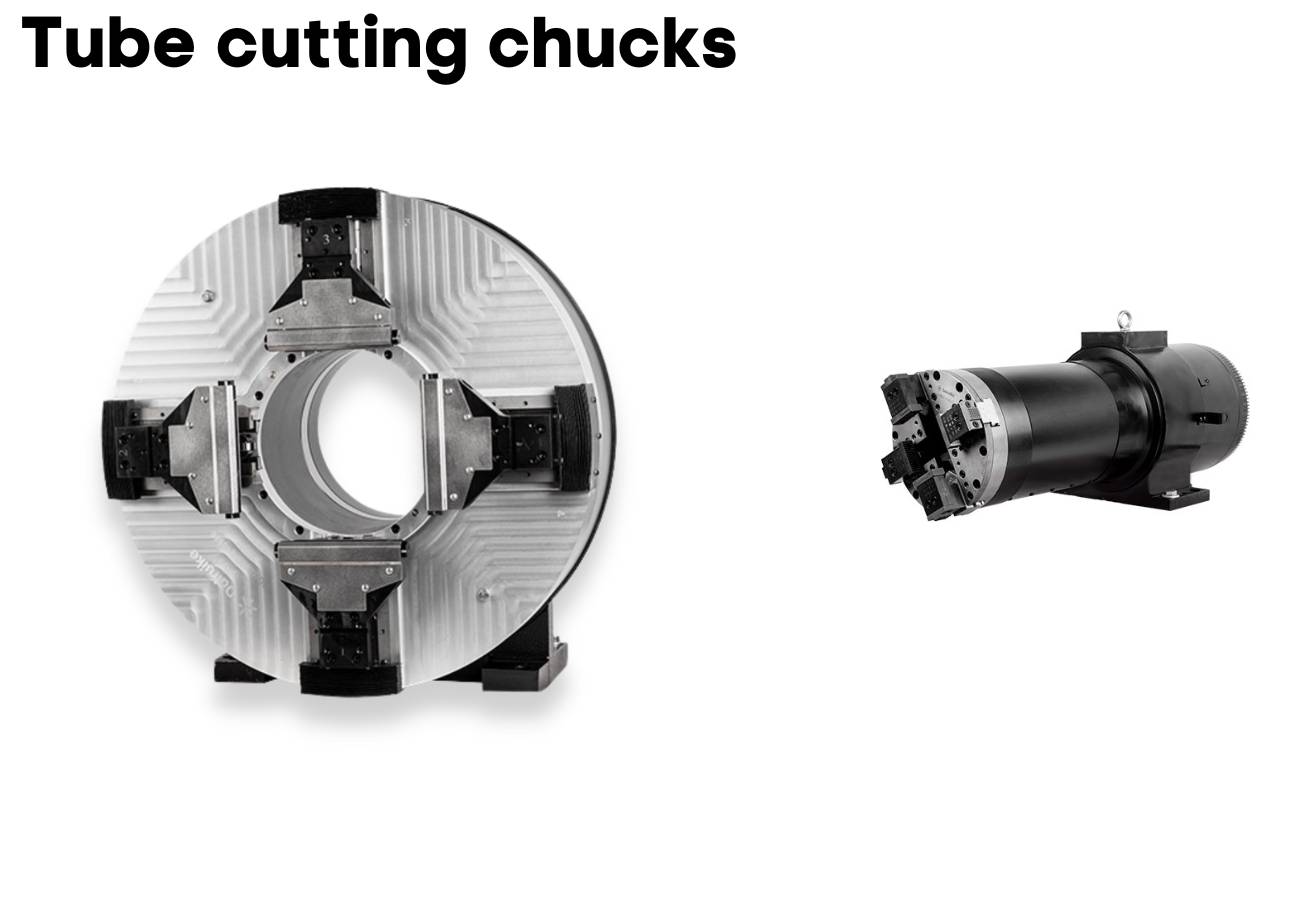

Customizable Front and Back Pneumatic Chucks

The laser tube cutting machines use the newest pneumatic chucks. Compared to the previous electric and manual chucks, the pneumatic chucks are more stable due to their physical drive characteristics. It can automatically center and clamp the workpiece with one key operation, and the clamping force is stable and reliable, and the size can be adjusted, and the customer can customize the chucks diameter according to the size of the workpiece.

In addition, the pneumatic chuck using a fully enclosed structure, all procurement parts for precision selection, parts excellence, all with the surface have dust-proof function, coupled with their own unique selection of materials and heat treatment technology process, greatly improve the service life of more than manual chucks, such as maintenance and use of proper methods, the use of product life up to 10 years or more, and can achieve long-term development to maintain the factory “Precision” quality, so that your investment needs long-term asset preservation, repeated clamping accuracy requirements are generally 0.01-0.03mm, the extreme speed per minute up to 3000 rpm.

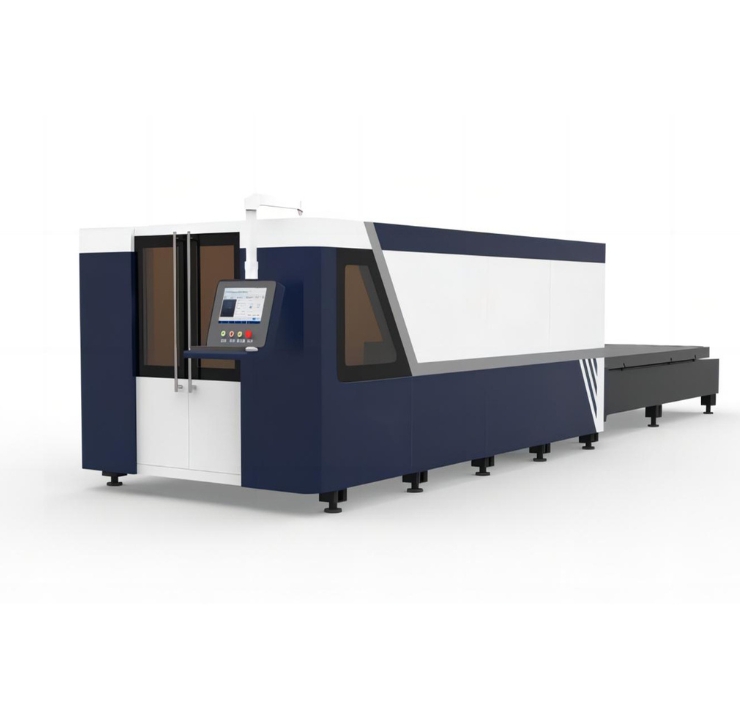

Model FSCUT3000S Pipe Laser Cutter CNC Control System

The FSCUT3000S pipe laser cutter CNC control system is a three-axis linkage control, which is an upgrade of the previous generation of FSCUT3000. The system supports the cutting of metal pipes of various shapes such as round, square, rectangular, I-beam, angle iron, channel, oval pipe, etc.

In addition the system has been upgraded and optimized with various other features:

1.L steel, channel steel, I-beam and many other special steel shapes seeking center and edge, to improve the cutting accuracy of special steel shapes

2. The workpiece with stable deviation of pipe surface can effectively compensate for the regular cutting deviation, reduce the accuracy requirement of raw materials and reduce scrap

3. Starting point and end point parameters integrated, it can solve the problem of cutting starting point power burning to the opposite side, solve the problem of thin tube falling off before cutting off causing the cutting position to leave a small tail.

Professional Tube Cutting Head for Laser Tube Cutting Machine

Pipe laser cutters use a sharp and slender laser cutting head, which has a smaller size and can be easily used for cutting I-beams, channels, angles and other limited space locations. The laser head can be reached freely without jamming.

The cutting head is connected to the CNC control board through the Z-axis height regulator for auto-focusing.The laser tube cutting head has an integrated height sensor that automatically senses the height of the cutting nozzle and the metal tube surface and transmits the data through the main board to accommodate the correct focus. The laser tube cutting head has an integrated height sensor that automatically senses the height of the cutting nozzle and the metal tube surface and transmits the data through the main board to accommodate the correct focus. This makes the laser tube laser cutting machine more intelligent and automated for metal pipe cutting.

Double Independent Circulation Industrial Water Chiller

The fiber laser cutting system is a process that cuts metal by converting electrical energy into a 1064nm laser beam. During this process, both the fiber laser source and the laser cutting head generate a large amount of heat.

Therefore, MOZLASER uses a dual cycle industrial chiller for water cooling the fiber laser source and the laser cutting head separately. To ensure the stable operation of the laser tube cutting machine. After testing, this machine can work continuously for 24 hours all day without any problems.

- Data Sheet

- Package Components Details

- Warranty and Service

Pipe Laser Cutter

| Machine Model | MZ-6012TS | MZ-6022TS | MZ-6035TS | MZ-6042TS |

| Round Tube Capacity | 6000mm- Φ20-120mm | 6000mm- Φ20-220mm | 6000mm- Φ20-350mm | 6000mm- Φ20-420mm |

| Square Tube Capacity | L20×L20mm-L80×L80mm | L20×L20mm-L150×L150mm | L20×L20mm-L240×L240mm | L20×L20mm-L290×L290mm |

| Laser Power Options | 1KW/1.5KW/2KW/3KW/4KW/6KW | |||

| Max Rotation Speed | 150rpm | |||

| Max Feeding Speed | 80m/min | |||

| Repeated Positioning Accuracy | ±0.01mm | |||

| Machine Voltage | Ac 380V 50Hz | |||

| Cooling Way | Water Cooling(Industrial Water Chiller) | |||

| Machine Max Load Weight | 0.5T | 1T | 1.5T | 2T |

| PARAMETERS ARE FOR REFERENCE ONLY, CUSTOMIZATION SERVICE IS AVAILABLE | ||||

2 year warranty for whole machine except consumables.

MOZLASER “TS” series laser tube cutting machine pipe laser cutters

The cutting principle of laser pipe cutting machine is not much different from that of flat laser cutting machine, both of them cut the metal by high energy laser beam. As a special laser cutting machine, laser pipe cutting machine is mainly for standard metal pipes (round, rectangular, oval, etc.), but also through the heterogeneous jaws on the profile (channel, angle, etc.) and part of the shaped pipe laser cutting, compared with the traditional processing technology, its advantages are the following aspects:

(1) high cutting accuracy, the contour accuracy can reach ± 0.05mm.

(2) smooth kerf, no burr-free, fine cutting seam, and less material loss.

(3) Non-contact processing, and the heat-affected zone of laser cutting is very small, almost no deformation.

(4) High cutting efficiency, can realize mass production.

(5) Good flexibility, using professional CNC system and nesting programming software, you can change or replace the product at any time.

As can be seen, professional laser tube cutting machine, can replace mechanical drilling, milling, sawing, stamping or cleaning burrs equipments and other equipment and hard tools that require different metal tube processing process, to achieve the complex tube structure of undercutting, chamfering, grooving or holes, scoring and other possible size and shape features of the processing, etc. it can be widely used in metal fabrication, kitchenware, lamps, automotive, medical equipment, the hardware, fitness equipment and other industries.