MOZLASER "FD" Series Sheet Metal Laser Laser Cutting Machine,High Power Laser Cutter

Double Pallets Sheet Metal Laser Cutting Machine Main Features:

- High laser power,The laser power can reach 12000W-30000W, which can easily cut 40-60mm carbon steel, stainless steel and other metal materials.

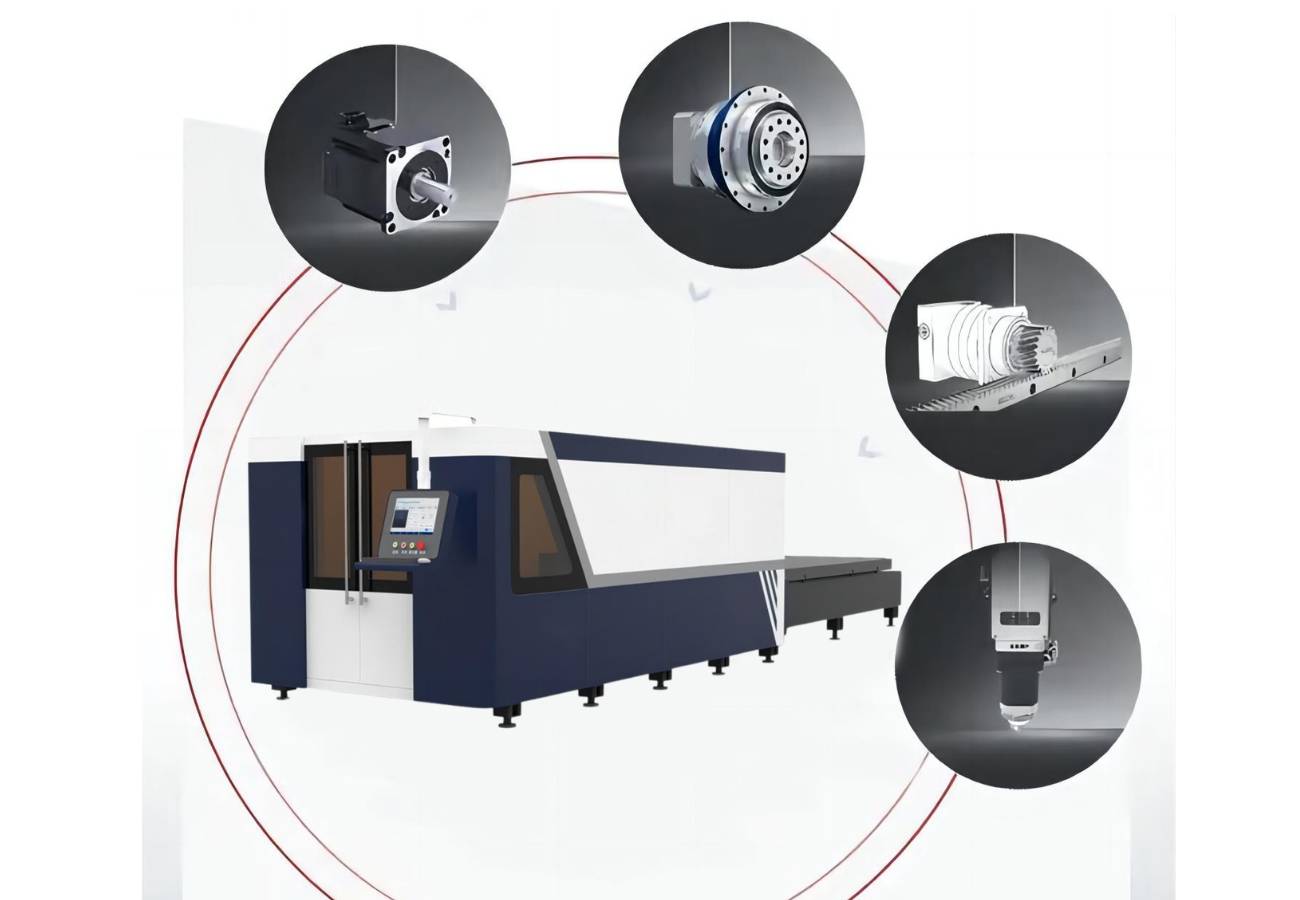

- Dual drive ,The Y axis uses a double-gear rack driving system with high precision linear guides and Japanese Yaskawa high speed servo motors.

- Industrial-grade,Industrial grade machine tools, high temperature annealing and double times gantry milling machine processing.

Ultra High Power IPG Fiber Laser

Ultra-high power laser cutter perforation and cutting speed advantages are obvious.

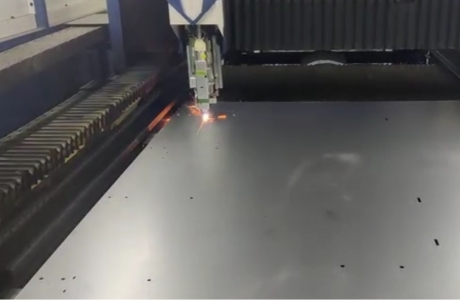

Ultra-high power laser cutter piercing and cutting speed advantage is obvious, high power fiber laser can also increase the piercing speed reduce the overall cutting time. For example, to cut 20mm thick carbon steel, with a 6kW laser, it would take you 3 seconds to pierce and then cut, but with a 10kW laser it would take less than a second to pierce the same thickness of 20mm plate. If there are many parts or parts with features that require many piercings, the nest cutting time will be greatly reduced by utilizing a higher power laser cutter.

Ultra high power lasers also cut faster and with better edge quality due to their energy. For example, using a 20KW fiber laser to cut 50mm thick stainless steel, compared to a 300A plasma cutter. Fiber laser cutting speed is more than 2 times faster. In terms of cutting cost, thinner carbon steel and stainless steel high power laser cutting machine can use compressed air for cutting, saving assistant gas and reducing the overall cutting cost.

Machine Base Frame with 20-Years Lifespan

MOZLASER’s high power laser cutter base frame all through the annealing process, eliminating internal stresses, strong and stable, 20 years without deformation. Annealing is a kind of metal heat treatment process, bed type castings need to be heat treated to improve its performance, refers to the metal is slowly heated to a certain temperature, maintained for a sufficient time, and then cooled at a suitable rate.

The purpose of the annealing process is to reduce hardness, improve machinability; eliminate residual stress, stabilize the size, reduce deformation and cracking tendency; increase the durability of the machine architecture, reduce steel brittleness, get the required toughness, plasticity. Then through high precision gantry milling processing, very good to ensure the service life of machine base and accuracy.

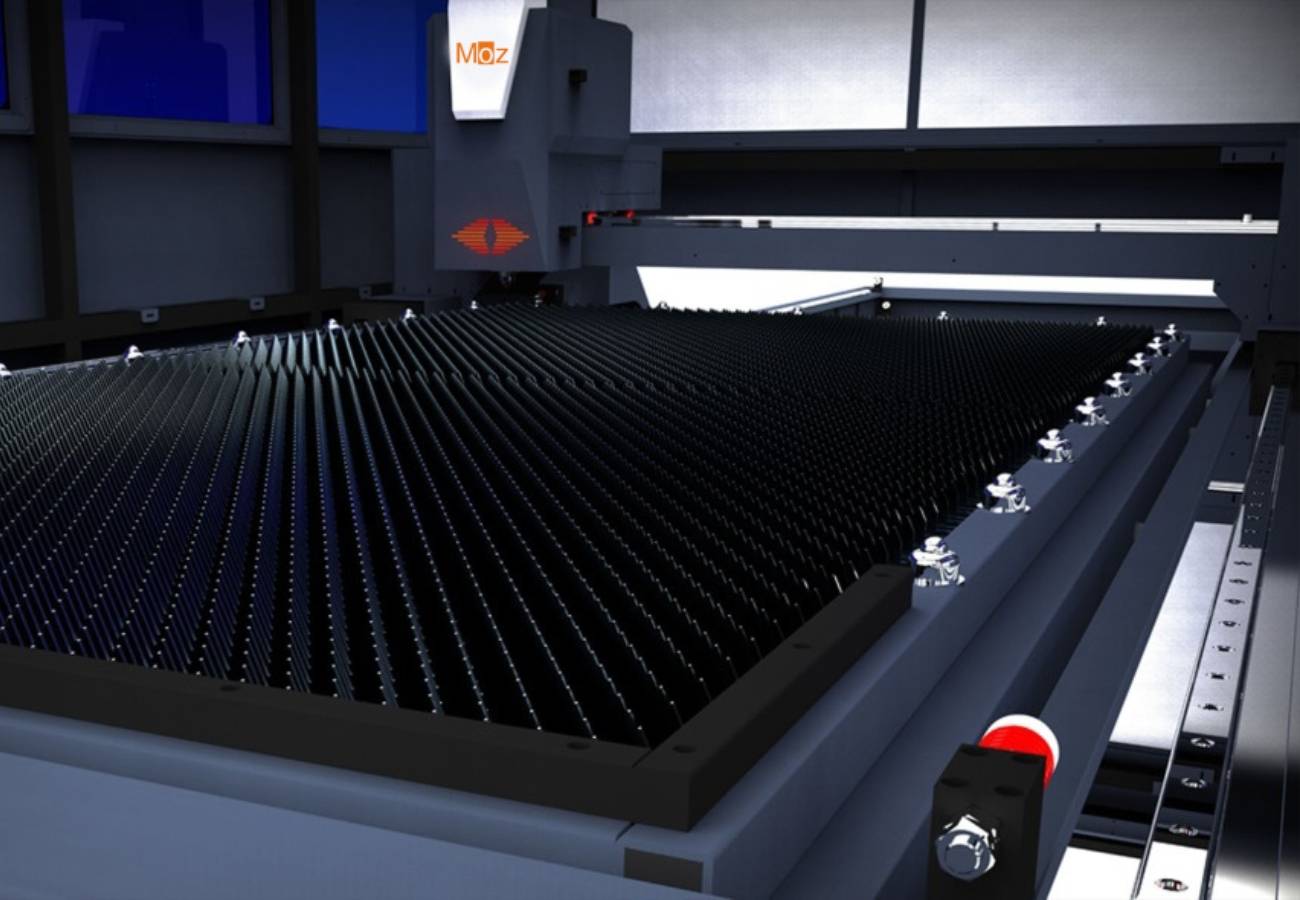

Sectional Extraction and Dust Removal System

MOZLASER high power laser cutting machine adopts sectional extraction and dust removal system: Dust removal system generally refers to the local operation for the cutting surface, specifically the local airflow for treatment, so that the local workplace is not polluted by harmful substances and maintain a good air environment. Dust removal system exhaust air unit consists of 4 parts: air collection hood, air duct, purification system and fan. The dust removal system can be divided into fixed dust removal and sectional mobile dust removal system according to the different ways of air collection. Fixed dust removal system is the overall machine structure all scattered with extractor, because the suction force of the extractor fan is scattered so the dust and smoke removal effect is not good. Sectional moving type dust removal system is open and closed set by the sensor set with the laser head cutting mobile, according to the position of the laser head can automatically open and close the air extraction port, the whole machine single air extraction port work to increase the air extraction port flow makes the air extraction effect increased by more than 200%, effectively ensure the smoke and cutting dust processing efficiency. CNC laser cutting fume and harmful gas purification system usually adopts the bag or electrostatic dust removal and adsorbent combination of purification method, high processing efficiency, stable working condition.

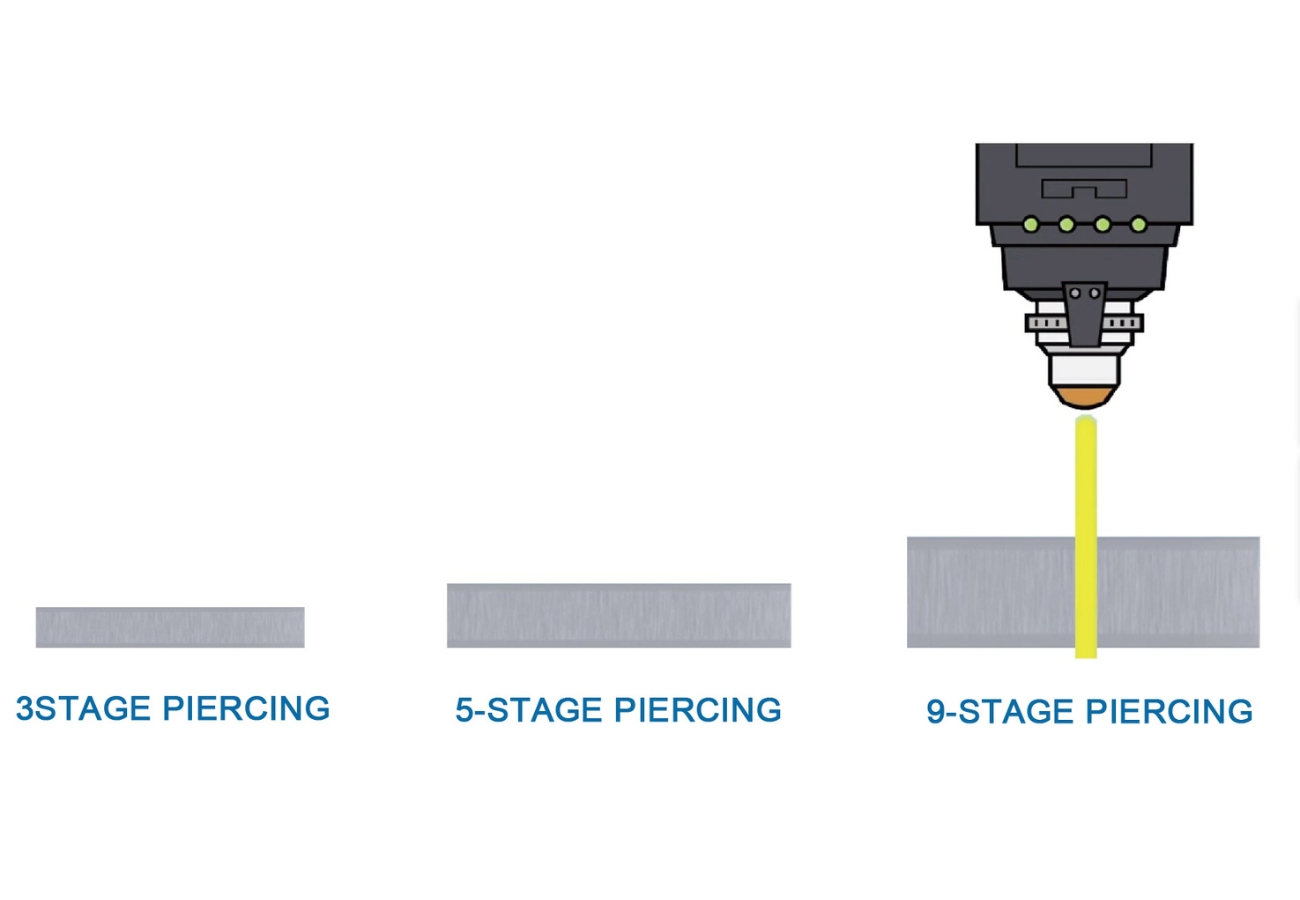

FSCUT 8000 Intelligent Universing Seriing Bus Laser Cutting CNC Control System.

FSCUT8000 is the latest generation of FRIENDESS Co,.Ltd laser cutting control system, compared with FSCUT2000, it is more only, the system debugging is more simple and humanized. Moreover, the operating interface is easier to learn and does not require long experience, and the average laser operator can be skilled in 5-7 days.The FSCUT8000 also has the following features:

1. 9 stages of piercing, can support ultra-thick plate piercing, enhance the piercing ability to cut thick metal plate

2. Intelligent cut ending, according to the cutting process, intelligent adjustment of the closing parameters, improve the smoothness of the inner cutting section and the integrity of the outer cutting surface

3. Automatic re-cutting, through the BLT cutting head built-in sensor intelligent judgment whether the cut is cut through, not cut through the intelligent back to cut again, improve the stability of the cutting process

CYPCUT BLT Series High Power Fiber Laser Cutting Head

FSCUT BLTSeries high power laser cutting heads include 3 models, covering 8KW-15KW, 15KW-20KW and 20KW-30KW ultra high power fiber laser power. With the FSCUT 8000 intelligent bus laser cnc control system system, it can handle various thicknesses of sheet metal cutting such as 30mm, 40mm, 50mm, 60mm, etc.

And the BLT series laser head contains each two layers of protective lenses on the top and bottom. This greatly reduces the possibility of damage to the internal optical focusing lens and collimation lens. With the modular design of the laser head and the anti-collision sensor design, there is no need to send the laser head back for repair if any module demaged. You can simply follow our instructions to replace the laser head module.

High Power and High Acceleration Servo Motors

Our sheet metal laser cutting machines are all driven by dual drive rack and pinion guides and high speed servo motors to match the cutting speed of the ultra high power laser. The acceleration of the motor reaches more than 1.5g, and the running speed of the machine is more than 100m/min.

In addition, other components of the transmission system are used in the world’s leading brands, such as HIWIN precision guide rails, YYC grinding level rack, reducer is also generally used in Japan’s SHIMPO or Germany’s NEUGART. Stability are guaranteed.

Double Independent Circulation Industrial Water Chiller

Our high power laser cutting machine uses the TONGFEI industrial water chiller, which is a listed company. It has been manufacturing and providing service in the field of water cooling equipments for more than 20 years. It has been known for its stable products and excellent service. For 12000W -30000W power sheet metal laser cutting machine, Tongfei is one of the best choices.

The most important feature of Tongfei industrial laser water cooler is that it is highly intelligent, with the core CPU connected to the sensor to control the temperature, the water temperature control accuracy ± 1 ℃. And connected to the module automatic sensors can achieve automatic fault diagnosis. Thus, it can remind users of emergency maintenance and treatment requires.

- Data Sheet

- Package Components Details

- Warranty and Service

High Power Laser Cutter with Exchangeable Tables

| Machine Model | MZ-1530FD | MZ-2040FD | MZ-2060FD | MZ-2560FD |

| Working Area | 1500×3000mm | 2000×4000mm | 2000×6000mm | 2500×6000mm |

| Laser Power Options | 3KW/6KW/8KW/12KW/15KW/20KW/30KW | |||

| Max Running Speed | 100m/min | |||

| Max Acceleration | 1.5g | |||

| X/Y Axis Positioning Accuracy | ±0.05mm | |||

| Repeated Positioning Accuracy | ±0.01mm | |||

| Machine Voltage | Ac 380V 50Hz | |||

| Cooling Way | Water Cooling(Industrial Water Chiller) | |||

| Machine Max Load Weight | 0.9T | 1.6T | 2.4T | 3.0T |

| PARAMETERS ARE FOR REFERENCE ONLY, CUSTOMIZATION SERVICE IS AVAILABLE | ||||

2 year warranty for whole machine except consumables.

MOZLASER “FD” series double pallets high power laser cutter with protective fence

With the development of the previous decade, sheet metal laser cutting machine has just become one of the most popular equipment in the metal fabrication industry.

Fiber laser processing is to high power, high efficiency, high precision development, with the development of the laser industry and the downstream industry demand changes, high power laser equipment has become a hot spot of market attention, especially the emergence of 12000W or even higher power fiber laser cutting machine, to promote the laser process more and more mature, and constantly break through the cutting thickness limit. It can be expected that, with the global renewal of laser cutting equipment, high power high-speed laser cutting machines will further replace traditional metal processing equipment with its significant efficiency and accuracy advantages, significantly improving the efficiency and quality of metal processing.

The advantages of high power laser cutter are very popular in the field of metal sheet cutting, and has gradually replaced traditional processing processes such as plasma cutting machine, flame cutting machine, as the core equipment for metal fabrication industry. From the appear of laser cutting machine, to fiber laser cutting machine to replace YAG, CO2 and other laser cutting equipments, and then to the rapid growth of high power laser cutting machine market share. Because of cutting thick plate and cutting efficiency requires, high power laser cutting machine has been the general trend.