Molds after high temperature and high pressure, it is inevitable to encounter the phenomenon of rust, injection mold rust causes cooling water back to moisture, molten material decomposition of gas corrosion, etc., usually coated with lubricating oil will also produce grease, these dirt in the mold surface buildup, but also affects the quality of the products produced, so the cleaning of the mold is the key.

So how to clean the injection mold? Here are a few traditional cleaning methods.

1、Manual cleaning

Manual cleaning is a traditional cleaning method in injection moulds industry, can clear simple dirt. But this cleaning method has more disadvantages, high labor costs, labor-intensive work, such as dead ends, blind holes, fine holes, sunbursts can not be cleaned, cleaning personnel’s inattention is also very easy to damage the mold surface.

2、Dry ice cleaning

Dry ice cleaning, also known as cold spray, is to use compressed air flow to push a medium, so that the medium impact surface, so as to clean the surface or surface treatment. So that the surface of the object to be cleaned dirt, oil, residual impurities, such as rapid freezing, thus condensation, embrittlement, stripped, and at the same time with the removal of airflow. Dry ice cleaning is suitable for cleaning large flat molds, such as foam molds, mold surface with jamming, corners, blind holes is not easy to clean; dry ice is a consumable volatile, storage is more troublesome, cleaning noise; cleaning must wear protective masks, masks, glasses and other protective tools. With other cleaning methods is different, dry ice cleaning generally do not need to remove the injection mold from the injection molding machine, can be cleaned online, while the use of other cleaning processes need to remove the mold.

3、Ultrasonic cleaning

Ultrasonic cleaning using chemical and physical process technology for cleaning, the process can be accurately adjusted in accordance with the cleaning task. Cleaning operation is simple, work without manual participation. The mold will be immersed in the cleaning fluid tank equipped with ultrasonic transducer, ultrasonic cleaning action is based on the principle of cavitation, that is, pressurization and suction alternately, in the suction phase to produce small bubbles, in the pressurization phase of small bubbles will burst, which will produce a strong liquid flow and turbulence, the dirt from the mold, “blasted off”. Material residues and materials such as coatings, oxides, oils, etc. are carefully but efficiently removed from the surface as well as from pits such as cooling and venting holes. In addition, the ultrasonic device dries the molds efficiently. Ultrasonic cleaning also has some disadvantages, cleaning is not thorough, only remove oil or rust, noise is relatively large, the work needs to bring earplugs.

4、 Electrolytic cleaning

Electrolytic cleaning through electrolysis and ultrasonic combination, can completely clean the mold, thoroughly clean the mold surface Vasquez, sulfide, carbon, oil, rust, etc., mold core dirt. Applicable to connector molds, precision gears, auto parts molds and other precision molds. Will not damage the mold substrate, including corners, bite patterns, plating, etc.. Advantages are labor saving, improved efficiency of mold maintenance, and reduced defective rate. Cleaning noise is less, simple operation. A

The newest cleaning method-laser cleaning

Laser cleaning technology is a new technology that has emerged in the past few years, it does not require consumables without special maintenance, can be directly for injection mold cleaning operations. MOZLASER through customer feedback and market research concluded that the injection molding industry molds are very suitable for the use of pulsed laser cleaning on the mold cleaning to improve the quality of injection molded products.

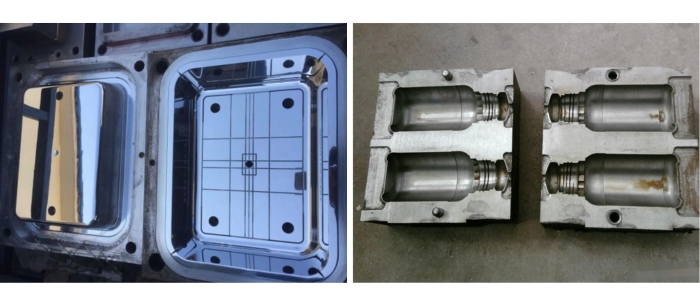

The following are some common types of molds that can be cleaned with laser cleaning technology:

Tire molds: Tire molds can be contaminated with sulfur compounds and oxidized layers. Laser cleaning can strip away the contaminants and oxidized layers without damaging the mold itself.

Plastic injection molds: Plastic injection molds accumulate plastic residues, grease and other dirt during use. Laser cleaning technology can completely remove contaminants and residues without damaging the precision of the mold. However, be sure to use a pulsed laser cleaner.

Die casting molds: Molds used for die casting of aluminum alloys, zinc alloys and other metals can also be laser cleaned to remove metal oxides and combustion products.

Rubber molds: Rubber molds produce black residue during the injection process that affects the quality of the product after the next use of the mold. Laser can effectively remove the black residue and oxidized layer.

Glass molds: glass molds will be left after the use of high-temperature combustion products and high-temperature oxidation layer, laser cleaning technology can solve this problem.

Casting Moulds: The carbon black, oxidized layer and other pollutants generated during the casting process can also be removed by laser cleaning technology.

Precision molds: molds that require high-precision processing, such as electronic parts, micro-mechanical components and other molds, laser cleaning can be effectively cleaned without damaging the mold surface.

Overall, compared with the traditional manual cleaning, dry ice cleaning and other methods, laser cleaning technology can be very good to help injection molding enterprises to solve the mold cleaning problem, and it does not require consumables, no special maintenance, cleaner and more environmentally friendly. Laser cleaning technology can also be developed through automation of the mold for automatic cleaning. It is one of the best methods and choices for most injection molding companies to clean their molds in the future.