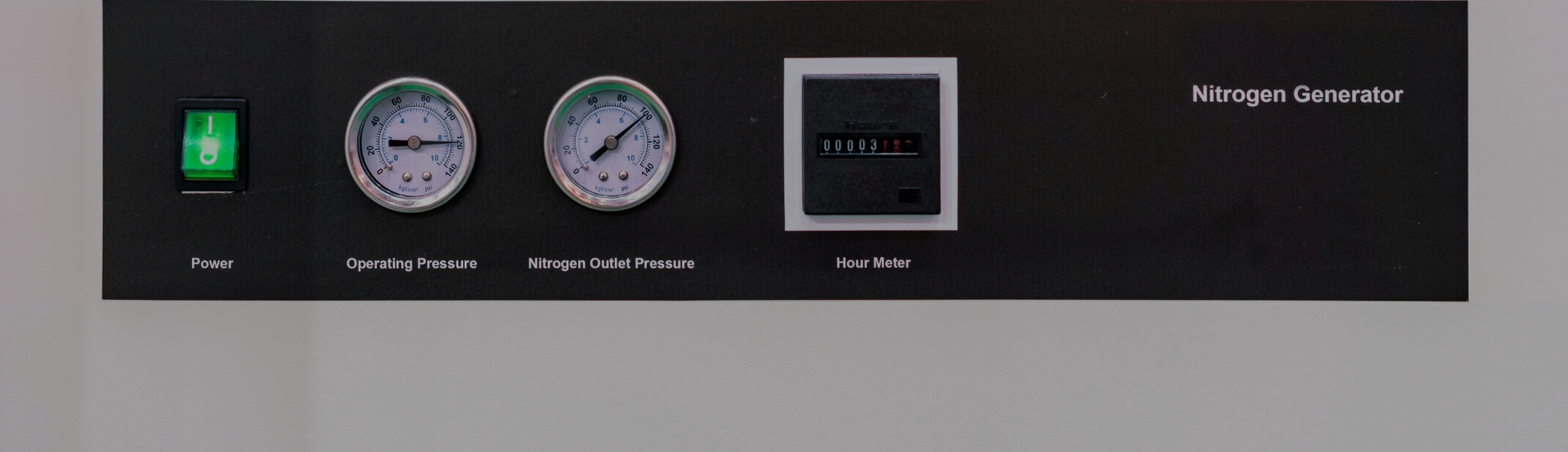

The smallest and most compact nitrogen generator of on-site industrial nitrogen gas.

Most nitrogen generator suppliers on the market can only supply single PSA nitrogen generator modules, requiring you to connect the air compressor and other filtration devices by yourself.

- Integrated design included screw air comprressor,air dryer,oil separator,and PSA nitrogen generator

- Specialized developed for laser welding application,no oil,no water. Purity standard is 5 ppm

- Very easy to operate and use, just plug it in 220V 50Hz power supply or 220V 60Hz power supply,it works.

Total solutions of nitrogen generator for laser welding from MOZLASER

There are many nitrogen generator equipment suppliers in the market, but they basically can not provide plug-and-play integrated design. Most of them were developed from food & beverage (storage & packaging),Chemical applications,Fire prevention and other industries’ requirements. They don’t even know what we exactly need in the laser welding applications. We all know that the nitrogen flow volume we need is very small in the laser welding application. Therefore, we and our customers all want to have an on-site nitrogen generator with a compact or tiny body that it can be directly plugged into the electricity can be used. It does not need to take up a lot of space to put.

MOZLASER has developed MZ-N2 series nitrogen generator after collecting feedbacks from local customers in China, North America and Europe, which is specially designed for laser welding application. The nitrogen flow rate is strictly designed to follow the flow rate requirement of the laser welding machine, and it can provide gas flow capacity 1 cubic meter/hour (for one laser welding machine), 3 cubic meters (for 3-4 sets of laser welding machines), 5 cubic meters (for 6-8 sets of laser welding machines).

Our main design concept for this nitrogen generator for laser welding is compact size and space saving. The fully integrated design incorporates a compressed air system, an air filtration and drying system, and a nitrogen generation system. It is also customized for the North American voltage system, providing 220V 60HZ three-phase power supply. No matter if your laser welding system comes from various brands in China, or if it is an IPG lightWELD system, it can help you provide nitrogen gas on-site saving your energy and costs.

All you need to do is plug it in , connect a gas tube to your laser welding machine, or IPG lightWELD. Then,it works.

Related products (3)

- About the PSA Nitrogen Generation Technology

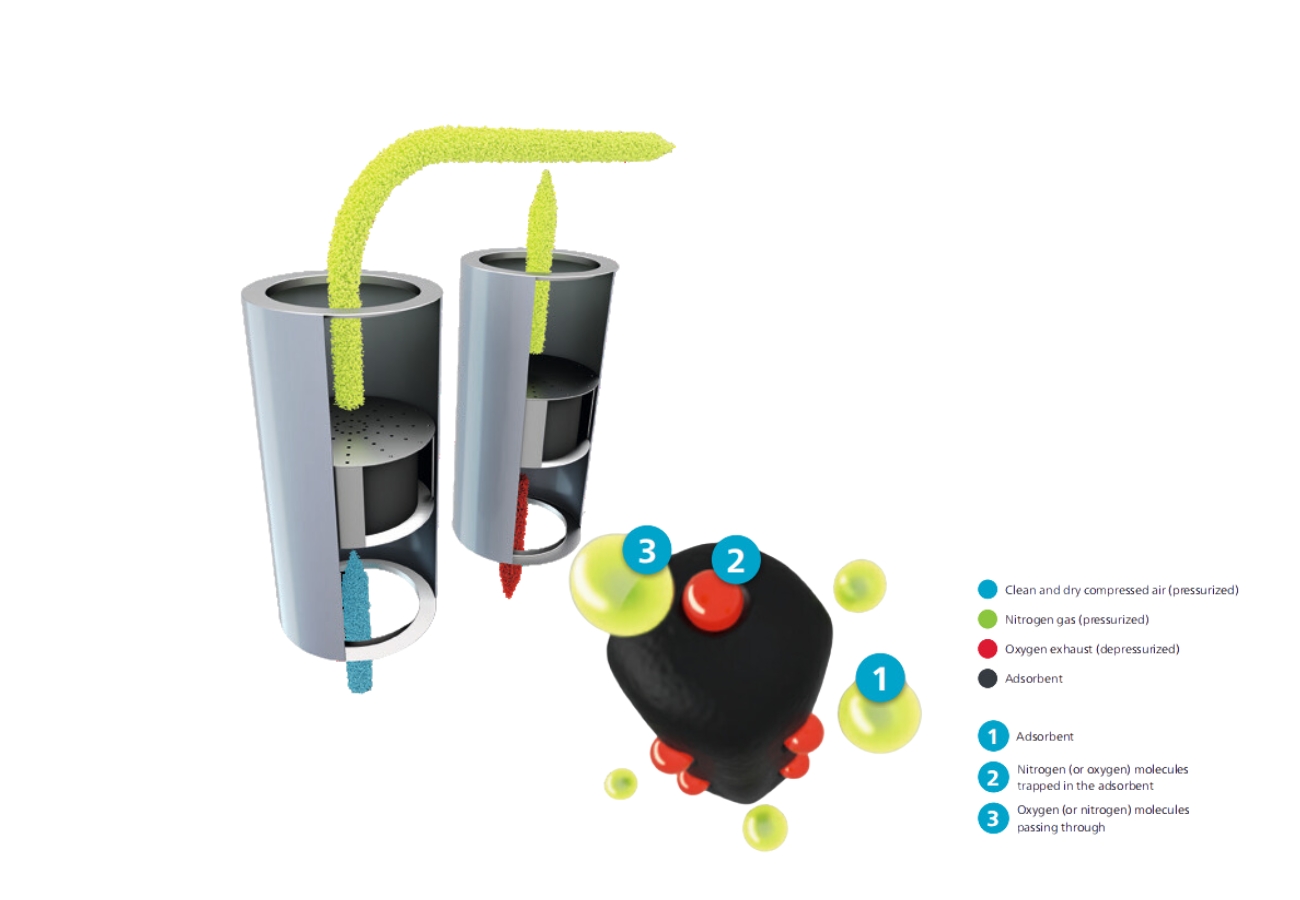

PSA nitrogen technology, i.e. Pressure Swing Adsorption, is a gas separation technology based on the principles of selective adsorption of adsorbent and desorption under reduced pressure.

Working Principle:

PSA nitrogen generator utilizes high-quality carbon molecular sieve as adsorbent to produce nitrogen from air under a certain pressure. Due to the aerodynamic effect, the diffusion rate of oxygen in the micropores of carbon molecular sieve is much larger than that of nitrogen, and oxygen is preferentially adsorbed by the carbon molecular sieve, while nitrogen is enriched in the gas phase to form finished nitrogen. Then the adsorbent will desorb the adsorbed oxygen and other impurities after depressurization to atmospheric pressure to realize regeneration.

Based on Pressure Swing Adsorption (PSA) technology, MOZLASER‘s nitrogen generators for laser welding application provide a continuous flow of nitrogen gas at desired purity.

MOZLASER New generation PSA generators will change the market of the gas supplying in the laser welding and cutting application.

As you know, laser welding applications require the use of argon or nitrogen gas to assist in covering the welding surface with a high-purity inert gas to prevent oxidation reactions with oxygen in the air during the welding process. It can result in blackened weld results or even excessive oxidation bubbles.

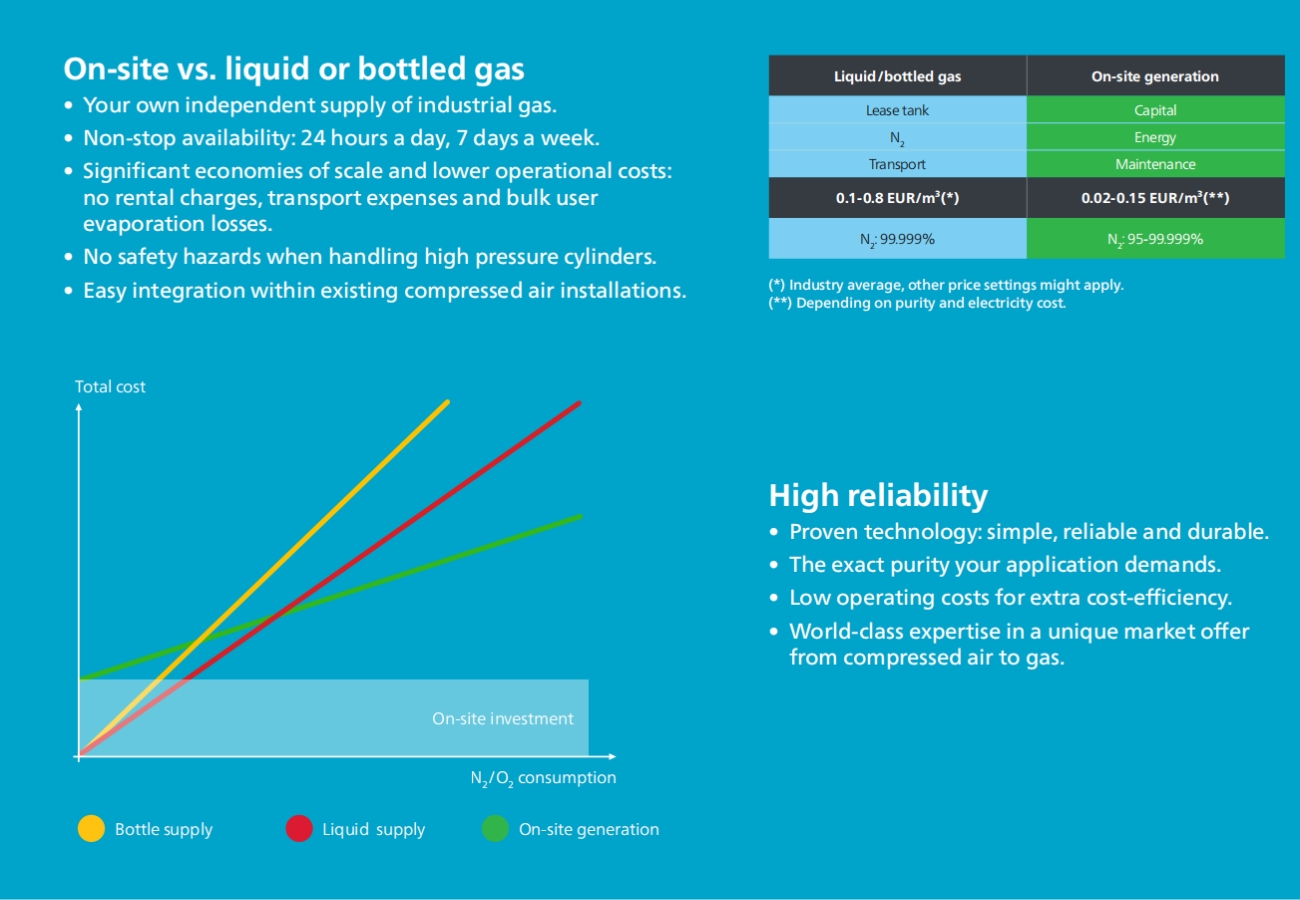

Traditional welding applications market gas supply generally supplied by bottled way, or liquefied nitrogen way. However, both of these supply methods are not investment cost efficiency, especially in some countries where the gas supply chain is not particularly good, thus the cost of continuous use of nitrogen is very high.

So MOZLASER has designed a series of nitrogen generators for laser welding applications. Nitrogen generators not only can provide a stable and continuous supply of nitrogen, but also reduce the cost of nitrogen to about 50% of the cost of canned and liquefied nitrogen if you use it for a period of 3-5 years.

No need. MOZLASER’s nitrogen generator for laser welding is integrated design includes compressed air,oil filtration moldule,cooling dryer and PSA nirogen generation system. Just connect our nitrogen generator to your laser welding machine. Then it works.

Nitrogen gas with 99.9% purity is usually recommended for laser welding. MOZLASER’s nitrogen generators provide a stable on-site supply of nitrogen gas with a purity of 99.95-99.99% for your laser welding.

Theoretical life of 5-6 years, the life of the molecular sieve is also affected by the oil or moisture in the compressed air. So we must do a good job of front-end filtration, provide clean and dry compressed air to it!