1 .Preface.

Cultural relics are the relics and remains of human beings in the process of historical development. The research on the conservation of cultural relics is of great significance to people’s understanding of human history, revealing the objective law of social development and promoting the development of society. Now the preserved cultural relics due to the age, the surface are more or less different degrees of pollutants, such as mold, dust, and insect spots and so on. Over the years, domestic and foreign workers for the protection of cultural relics surface pollutants cleaning has carried out a lot of work. Commonly used cleaning methods are mainly mechanical cleaning and chemical cleaning. These means mainly rely on the experience and techniques of the operator. Mechanical means may result in the removal of substances on the artwork as well, while chemicals may penetrate the artwork, destroying the pigments and damaging the artifacts. Both means may lead to irreversible damage to the artwork.

Laser cleaning as a new type of cleaning technology has been more and more widely used in various fields. Laser cleaning is the use of laser beam characteristics, through the focusing system can make the laser beam gathered into different sizes of spot diameter, in the laser energy under the same conditions, different spots of the laser beam, the resulting energy density or power density is different, so that it can be convenient to control the cleaning of the required laser energy. The laser can achieve a high degree of concentration in time and space. Laser cleaning utilizes these features to effectively remove contaminants.

2.Laser Cleaning Methods and Features

Traditional cleaning methods include mechanical cleaning, chemical cleaning and ultrasonic cleaning, although they are widely used in the cleaning industry, but in environmental protection and high-precision requirements of its application is greatly restricted. Mechanical methods can not meet the high cleanliness cleaning requirements, while the chemical cleaning methods can easily lead to environmental pollution, the cleanliness obtained is also very limited; especially when the dirt composition is complex, it is necessary to use a variety of cleaning agents to repeat cleaning to meet the requirements of surface cleanliness. Ultrasonic cleaning of submicron dirt particles can not help, the size of the cleaning tank limits the scope and complexity of the cleaning components, and cleaning the workpiece drying is also a major problem. Laser cleaning technology is a new type of cleaning technology developed rapidly in the past decade, in many fields is gradually replacing the traditional cleaning process. It can adapt to a variety of surface dirt cleaning, environmental pollution is very small, can also be done without damage to the substrate. At present, the method has become a supplement and extension of the traditional cleaning methods, has a broad application prospects. Compared with traditional cleaning methods, laser cleaning technology has some unique advantages:

(1) laser cleaning is a selective cleaning, that is, the object to be cleaned with selective, this technology can make the substrate surface intact. For different dirt on different substrate surfaces, the laser parameters (such as spot size, single pulse energy, pulse width, repetition frequency, etc.) can be set to selectively clean the dirt without damaging the substrate.

(2) Environmental friendliness of laser cleaning. Laser cleaning waste are basically solid powder, small size, easy to store, basically no pollution of the environment, is a “green” cleaning process.

(3) The non-contact nature of laser cleaning. Traditional methods are often close to the operation, cleaning the surface of the object has a mechanical force, easy to damage the surface of the object. Laser cleaning is a non-contact processing, can be convenient to achieve long-distance operation, can be transmitted through optical fibers, and robots or manipulators, can clean the parts of the traditional methods are not easy to reach. Energy is transmitted in the form of light without the need for mechanical contact. This makes it possible to clean the surfaces of very fragile materials.

(4) Laser cleaning removes different types of contaminants from the surfaces of a wide range of materials and achieves a high degree of cleanliness. Laser cleaning has been successfully used to clean different types of contaminants on a wide range of materials such as marble, limestone, sandstone, pottery, snowflake plaster, cooked gypsum, aluminum, bone, calfskin paper, and organics, etc. The types of contaminants include dust, mud, rust, paint, and oil.

(5) Can be accurately located. The laser beam can be precisely positioned on the surface of the material to be cleaned, and its spot area can be adjusted from a few millimeters to 1 cm. Irregular or hidden surfaces can be cleaned. The laser head or the laser-conducting fiber is placed on a movable three-dimensional platform, which allows the laser beam to be positioned on the surface of the material to be cleaned. Computer control can be used to make this positioning more accurate and automated.

(6) Instant control and feedback of laser cleaning. Real-time monitoring of the material surface reflectivity or laser-induced surface acoustic waves through CCD cameras and probe light to determine the cleaning effect. According to the cleaning effect, the laser power can be turned off at any time during the cleaning process to terminate the cleaning. This process can be completely intelligent.

(7) It can effectively remove contaminant particles of micrometer scale and smaller sizes. The scale of some pollutants may reach the micron or even submicron level, such as electronic printed circuit boards in the etching and spray plating process of dust particles. General methods are difficult to remove such pollutants. Currently has been successfully used short-pulse ultraviolet laser to remove the surface of the object size in 0.1μm or so of the tiny particles, and has been applied in industrial production.

(8) Laser cleaning equipment can be used stably over a long period of time, generally requiring only electricity and maintenance costs, low operating costs, and can be easily automated.

Laser cleaning is usually classified into four methods.

① Direct laser cleaning method, through a pulsed laser directly scanning the object contamination layer

② Liquid film laser cleaning method, the first object surface liquid film precipitation, and then scan the surface with a laser to let the liquid film and dirt at the same time high-temperature gasification stripping, this method is common in PCB circuit boards.

③ Gas-assisted laser cleaning method, that means when you use pulse laser scanning the surface of the object at the same time using of inert gases such as argon, nitrogen and other gases blowing the surface of the object, so that the pollutants peeled off the surface, immediately be blown away to prevent secondary pollution. At the same time the inert gas can also effectively protect the surface of the artefacts to prevent oxidation.

④ Laser cleaning supplemented by chemical cleaning method,This method is do the laser scanning pretreatment, then use of non-corrosive chemical cleaning agent for cleaning.

Number 1-3 laser cleaning methods are mostly used for industrial and daily cleaning of goods, the fourth commonly used in the protection of works of art and cultural relics.

3. Laser Cleaning Technology in the Field of Cultural Relics Protection Applications

3.1 Stone cultural relics of laser cleaning and protection

Stone carvings and stone carvings and other age-old stone artifacts, mainly made of marble. Exposure of marble to the surrounding environmental conditions can lead to the generation of surface layers, which is often referred to as the “dirt layer”. These include: soil-dust deposits, which can often be found in artworks excavated from ruins or on display. They contain large amounts of carbonates, aluminosilicates and various reddish-brown iron oxides. The black, dendritic buildup of dirt, which occurs in areas that are not exposed to rain, consists mainly of gypsum, calcite, silicates, black particles, dust deposits, soot, etc. When cleaning stone artwork, there are two main requirements: to remove the layer of dirt, to maintain the original shape of the artwork and prolong its life, and to maintain the original surface, thus enhancing the details of the carvings. Traditionally, marble artwork is cleaned using chemical or mechanical means. These traditional methods often cause damage to the artwork itself due to poor control.

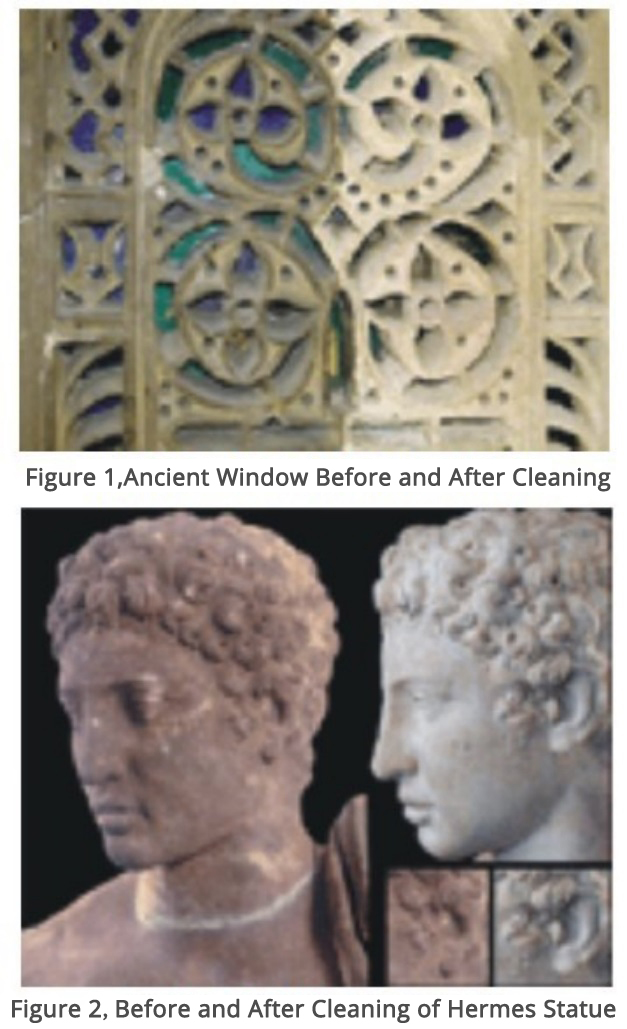

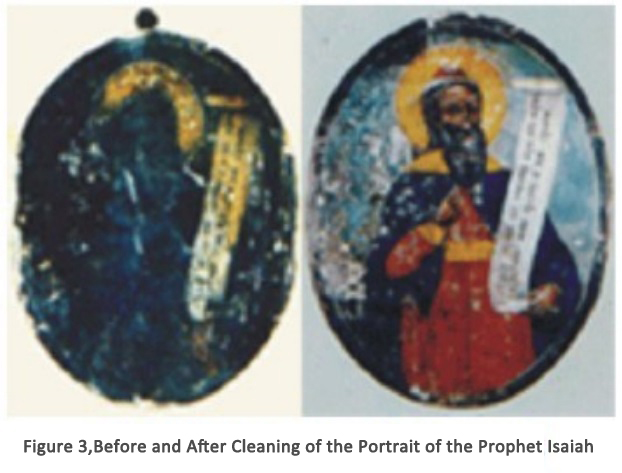

Compared with these traditional cleaning methods, in the laser cleaning process, laser cleaning technology can accurately control the energy input as well as the role of the location, in the complex surface control of the beam’s role in the location, to achieve the removal of dirt without damage to the stone substrate. 1992 September, UNESCO’s World Cultural Heritage Organization to commemorate the 20th anniversary of the founding of the organization, the implementation of the very famous Amiens Cathedral repair project in the United Kingdom. Church of Amiens, England, the very famous repair works. The very fine marble carvings on the west side of Amiens Cathedral’s Notre Dame Gate were the key to the project. In the one-year maintenance project of the Virgin Mary’s door, maintenance personnel with the help of laser, laser beams to remove the black dirt layer covering the marble carving pattern on a few millimeters thick, the original color of the marble surface is reflected, so that the exquisite carvings regain their luster. Another example, one of the most important stone carving collection in Britain, the stone carving collection by laser cleaning, also got the same effect. People used an electron microscope to observe the surface of the laser-cleaned stone carvings, and found that there was no change in the structure of the stone after the laser cleaning, and that the cleaned surface was both smooth and flat, with no damage. Lithou Sintirissis, a private Greek company, in conjunction with the Institute of Electronic Structures and Lasers of Crete, Greece (IESL-FORTH), cleaned and protected the glass windows (which had lost their original color due to contamination by stucco) of the Islamic art collection of the Benaki Museum in Athens. The researchers used a Q-tuned Nd:YAG laser with a wavelength of 1064 nm to clean the stucco contaminants, and Figure 1* shows a comparison of the details before and after cleaning. Laser cleaning and conservation of the Hermes sculpture in the excavated remains of Ancient Messinia in Peloponesse, Greece, by Prof. P. Themelis of the Ancient Messinia Museum. A Q-tuned Nd:YAG laser with a wavelength of 1064 nm was used, and Figure 2* shows a comparison of the details before and after laser cleaning.

3.2 Laser Cleaning and Protection of Oil Paintings

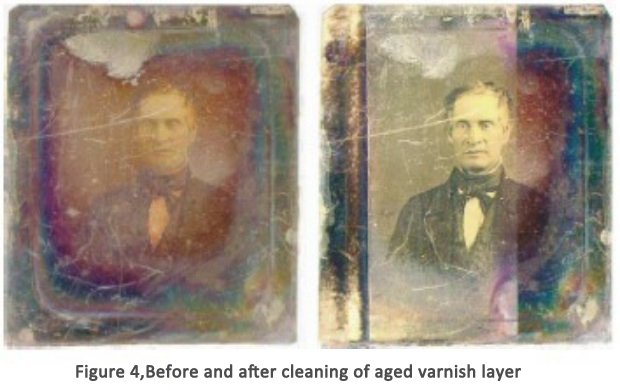

In western paintings, oil paintings are the main focus. Most of the oil paintings have a layer of varnish with a thickness of 0.05-0.08 mm on the surface. It protects the surface of oil paintings and improves the color. However, due to the collection and photochemical effect, the varnish layer on the surface is prone to aging, forming a black, solid film layer. In addition, dust and other external pollutants can affect the original color of the paintings and cause visual distortion of the paintings. Conventional mechanical and chemical cleaning may cause material damage to the surface of the paintings, or damage to the pigments by chemical substances. This can cause irreparable damage to the painting. Compared with these traditional methods, the laser cleaning and protection technology has a higher energy as well as the controllability of the action position. Ultraviolet lasers, due to the high energy of a single photon, use the photodecomposition effect to destroy or weaken the pollutants between the realization of the stripping, to achieve the purpose of cleaning. This process is a “cold” process, and does not produce thermal effects on the surrounding area. Therefore, will not have a great impact on the substrate. Currently, researchers are using ultraviolet excimer lasers for laser cleaning and protection of the portrait of the prophet Isaiah on the Holy Mountain (Mount Athos) in Greece in the 17th century, and Figure 3* shows a comparative picture of the portrait of Isaiah before and after laser cleaning.

Valerie V. Golovlev research group were compared with different wavelength cleaning to remove the effect of aging varnish layer, as shown in Figure 4*, the left side of the wavelength of 1064 nm infrared laser cleaning results, the right side of the wavelength of 532 nm green light laser cleaning results. From the experimental results, it can be found that the removal effect of the green light laser with a wavelength of 532 nm is more obvious.

In the protection of cultural relics of paintings, laser cleaning technology can be used to repair the damage of paintings due to smoke caused by fire, in addition to removing the aging varnish layer. Figure 5* shows the effect of using a UV laser to repair an oil painting damaged by fire.

Internationally, laser cultural relics cleaning and protection technology has been widely used in the cleaning and protection of museum relics and buildings. Many examples have proved that laser cleaning is an effective means for the cleaning process of cultural relics and paintings. For the stone substrate of cultural relics cleaning generally choose infrared Nd: YAG laser, its cleaning mechanism is mainly based on the light and the material generated by the force effect to remove surface pollutants. For paintings, the type of surface pollutants and the combination of the way and stone materials are very different. Infrared lasers cannot remove surface pollutants due to their long wavelength and low single photon energy, and increasing laser power will cause burns on the substrate of paintings. Therefore, in the cleaning and protection of painting leveling generally use shorter wavelength visible light, or ultraviolet laser for cleaning and protection. The cleaning mechanism is based on the cold ablation that breaks the bond, and its thermal effect is small or negligible. There is no thermal damage to the artwork itself.

4. Conclusion and advantages of laser cleaning

Laser cleaning technology is a non-contact cleaning technology, compared with the traditional cleaning methods it can be cleaned on a variety of surface contaminants, minimal pollution of the environment, and at the same time can be done without harming the substrate. At present the method has become an important supplement and extension of the traditional cleaning methods.

Advantages:

- MOZLASER developed the first domestic pulse flat top light fiber high power laser laser cleaning machine.

- Non-contact cleaning, no damage to the parts substrate.

- Precise cleaning, can realize precise position, precise size selective cleaning.

- without any chemical cleaning fluid, no consumables, safe and environmentally friendly.

- Simple operation, power can be, can be handheld or with the robot to achieve automated cleaning.

- cleaning efficiency is very high, saving time.

- laser cleaning system is stable, almost no maintenance.