HVAC Duct Manufacturing Upgrade Needs a Boost from Laser Applications

Air Ducts Are Mainly Used in Industrial and Construction Projects, Application Areas Mainly Involve: Electronic Industry Clean Plant Purification System, Pharmaceutical and Food Aseptic Workshop Purification System, Hotels, Shopping Malls, Hospitals, Factories and Office Buildings of the Central Air Conditioning System, Industrial Pollution Control with Dust, Smoke, Oil and Other Exhaust Ducts, Industrial Environment or Post Comfort with Air Supply Ducts, Coal Mine Gas Extraction with Gas Extraction System, Coal Mine Environment Air Supply and Return System for Control… Etc.

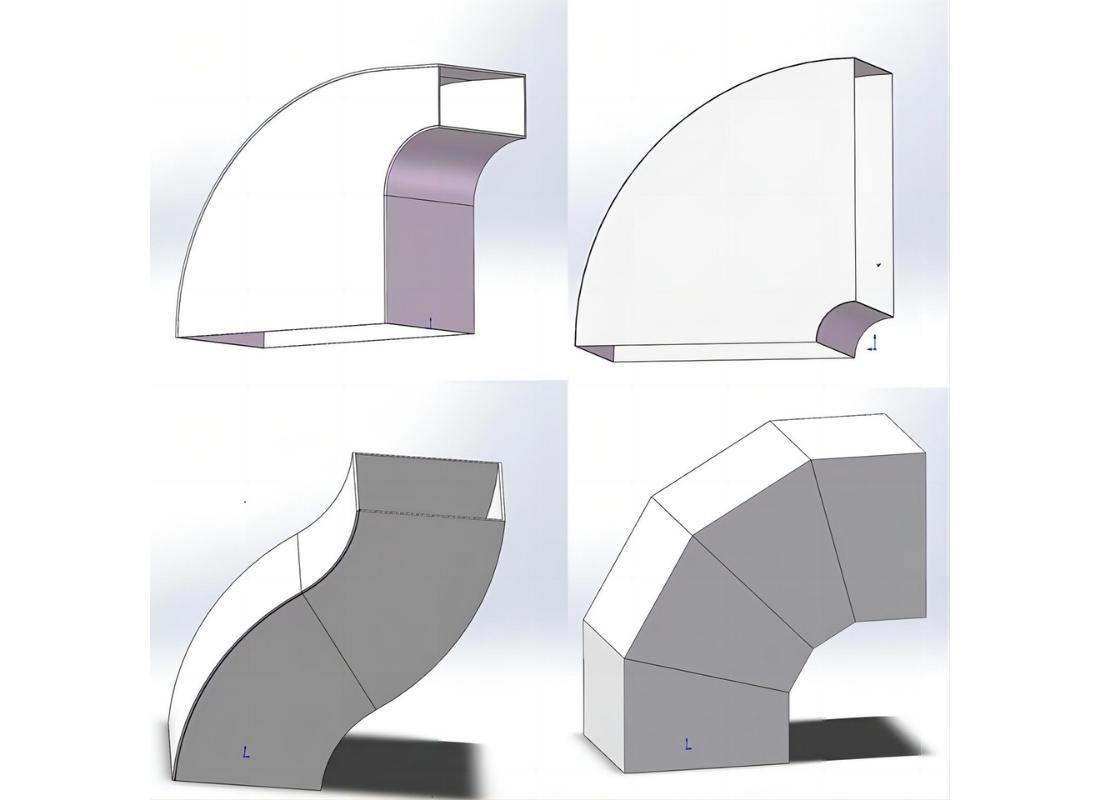

With the Progress of the Times, the Requirements for the Precision and Aesthetic Appearance of Air Ducts Are Getting Higher and Higher. So Laser Duct Raw Material Cutting and Laser Duct Welding Instead of Plasma and TIG Has Become a Big Trend.

Progress in Laser Technology is Upgrading the Ventilation Duct Manufacturing Industry

This Change is Reflected in an Upgrade in 2 Aspects.

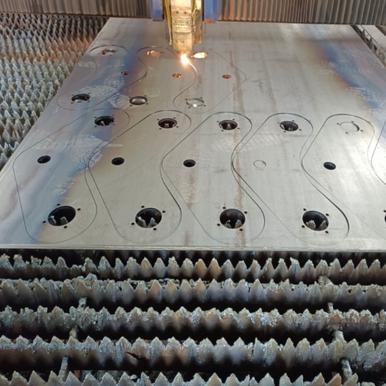

In the First Aspect, Fiber Laser Cutting Machine is Replacing Traditional Plasma Cutting Machine.

Plasma Cutting is Smoky and Dusty, Large Burrs in the Cut Material, Poor Accuracy and Very Slow Speed.

But Laser Cutting is the Latest Science and Technology, Cutting Speed is 2-3 Times Faster Than Plasma Cutting, Accuracy Can Reach ±0.05mm, and No Burr, No Need Secondary Processing.

The Second Aspect, Laser Duct Welding Machine is Replacing Traditional TIG Duct Welding Machine.

We All Know That Tig Welding or Electric Welding Needs Operators with Rich Welding Experience. So a Experienced Welder’s Salary is Not Cheap and Cause the Enterprise’s Labor Cost is High. and the Uv and Particle Radiation is Very High, Which is Also Very Bad for the Health of Workers. Laser Duct Welding Operation Does Not Require Skilled Welders, 2-3 Times the Speed of Plasma, and the Laser is Visible Light, Particle Radiation Pollution is Much Smaller.

According to the China HVAC Duct System Manufacturing Association, About 60% of China’s HVAC Duct System Manufacturers Have Replaced Traditional Plasma Cutting and Tig Welding with Laser Cutting and Welding, and This Replacement Rate is Speeding Up.

Duct Welding by Handheld Laser Welding Machine at Customer’s Workshop

- Galvanized Steel or Stainless Both Can Be Welded

- The Latest Welding Technology of the 21st Century

- At Least Double Welding Speed Compared to TIG Welding

- Laser is Visible Light,No UV Radiation More Safe

Please Choose Different Laser Duct Welding Power According to the Different Welding Thicknesses and Materials (4)

The Advantages of Laser Technology Are Driving It to Replace Traditional Cutting and Welding Methods

Why Do We Believe That Laser Duct Welding Machines Will Finally Replace Traditional Argon Arc Welding and Electric Welding in the Near Future?

MOZLASER Has Extensive Experience in the Air Duct and HVC Industry and Has Been Providing Excellent Laser Cutting Machines and Laser Welding Machines to the Air Duct Manufacturing Industry, and Has Obtained a Lot of Market Data from a Large Number of Air Duct Manufacturing Customers.

Data Shows That 60% of Local Chinese Market Ducts Manufacturers Have Replaced Their Plasma Cutting Equipment with Laser Cutting Machines. and Laser Air Duct Welding Replaces the Original Tig Welding. This Replacement is Speeding Up. As We Know the Other 40% of Customers Are Also Considering Replacing Their Old Machines with Laser-related Equipment to Upgrade Their Production.

So if You Also Want to Make More Money in the Next Round of Manufacturing Upgrades. You Can Call Us to Talk About Laser Cutting and Laser Welding Equipment for HVAC Ducts Manufacturing.

Electricity Consumption

Laser Protection Lens

Welding Wire (If Using Wire Filler Welding Function)

Usually for Air Duct Manufacturers They All Weld Thin Galvanized Sheets or Stainless Steel, We Recommend Choosing 1500w Laser Power. if You Need to Weld Other Thicker Materials, Please Get in Touch with Us for Advice.

We Are a Laser-related Equipment Provider and Service Provider.

We Can Provide Laser Air Duct Welding Machine.

And Also Provide Laser Air Duct Cutting Machine.

We Recommend Argon Gas or Nitrogen.