MOZLASER F Series Flatbed Laser Cutter with Large Working Size and High Laser Power

Mian Features of MOZLASER Flatbed Laser Cutting Machines

- Stable,Thick square welded machine structure and annealed to educes internal stress and risk of deformation

- High-speed,Exclusive double rack drive with servo motor drive system, the speed is 2 times faster than ordinary stepper motor

- Large Cutting Range,”F series” flatbed laser cutter standard cutting size is 1300×2500mm, the maximum custom size up to 2000×3000mm

High-strength and High-precision Machine Lathe Bed Ensure Cutting Accuracy and Machine Solidity and Stability

We were the first local supplier using a precision milling machine to finish milling the machine guide and rack mounting surface to ensure absolute flatness of the plane, thus guaranteeing the running and cutting accuracy of the flatbed laser cutter.

We are also the first local supplier to use a 100mm standard square tube to weld the machine base, which is twice as strong and long-lasting as other suppliers’ laser cutters.

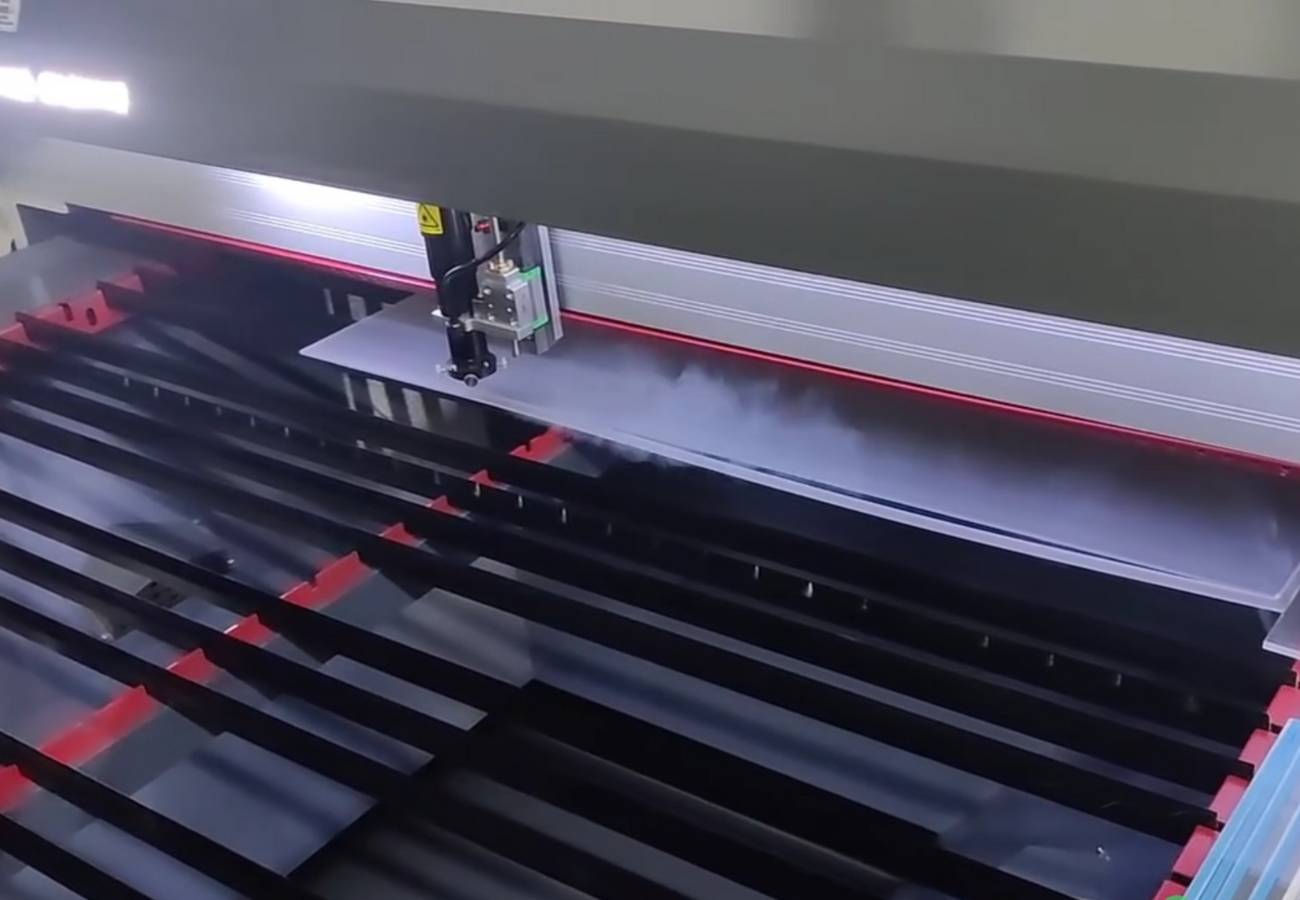

Dual Smoke Extraction System Structure Design

Many of MOZLASER’s customers have complained about the heavy smoke when using flatbed laser cutting machines to cut wood or plastic. Usually the laser cutting machine can’t extract the smoke and dust well, which makes the factory environment very bad.

Our technical team has designed a dual smoke extraction system for this reason, with one smoke extracting duct at the bottom to open and extract smoke and dust in sections as the laser head moves. The other one follows the laser head from the top and extracts the smoke and dust at any time.

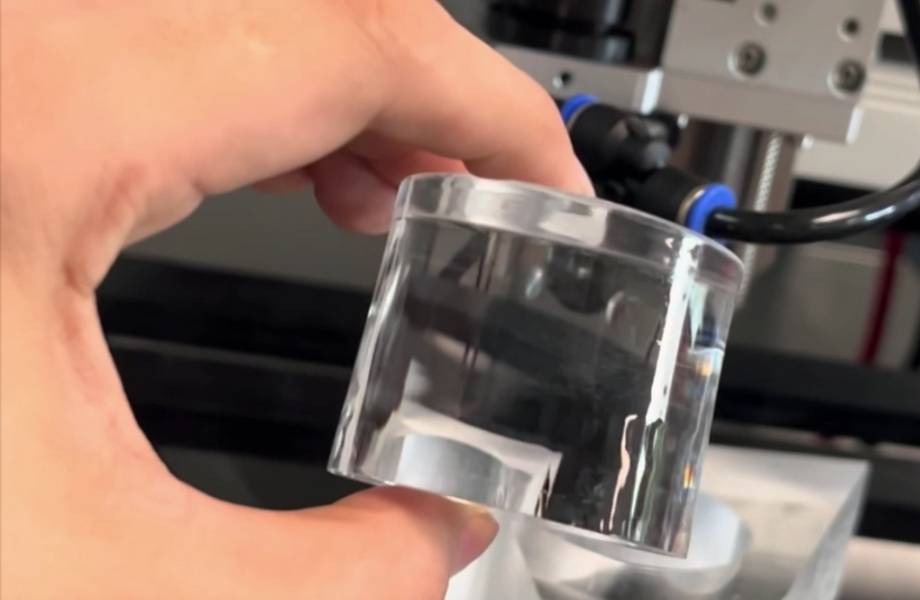

For Ultra-Size and Thick Material Cutting Such As Acrylic, Wood, Plywood, MDF, Etc.

MOZLASER offers three different large cutting sizes for this flatbed laser cutting machine including 1300 x 2500mm, 1500 x 3000mm, 2000 x 3000mm. The machine is designed for cutting wood, plywood, acrylic and other materials in the advertising sign making and crafts industries.

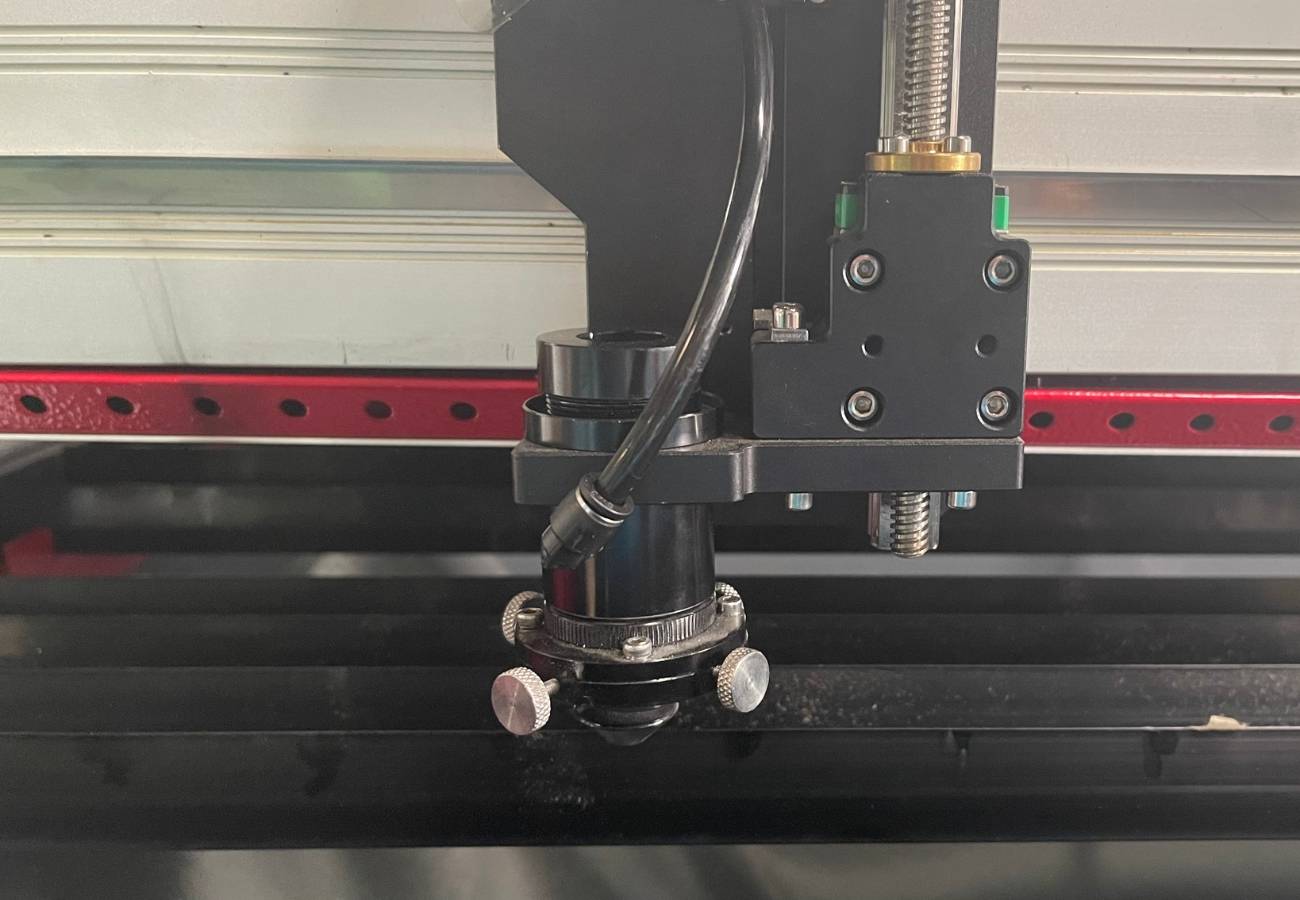

The flatbed laser cutter with auto-focus laser head, the focus is automatically adjusted for different thicknesses of materials. No need to adjust the focus manually, no matter how thick you cut the material, the distance sensor on the laser head can automatically sense the surface of the material and automatically adapt the cutting focus.

Dual Gear Rack and Servo Motor Driving System

In fact this is the structure used for the fiber laser cutter that we have devolved and applied to the CO2 flatbed laser cutter. The goal is to make this machine the best CO2 laser cutter on the market.

MOZLASER adopts DIN6 high precision level grinding machine gear rack, which is more accurate and the gear rack coupled with servo motor is more stable and better precision than stepper motor with common belt drive.

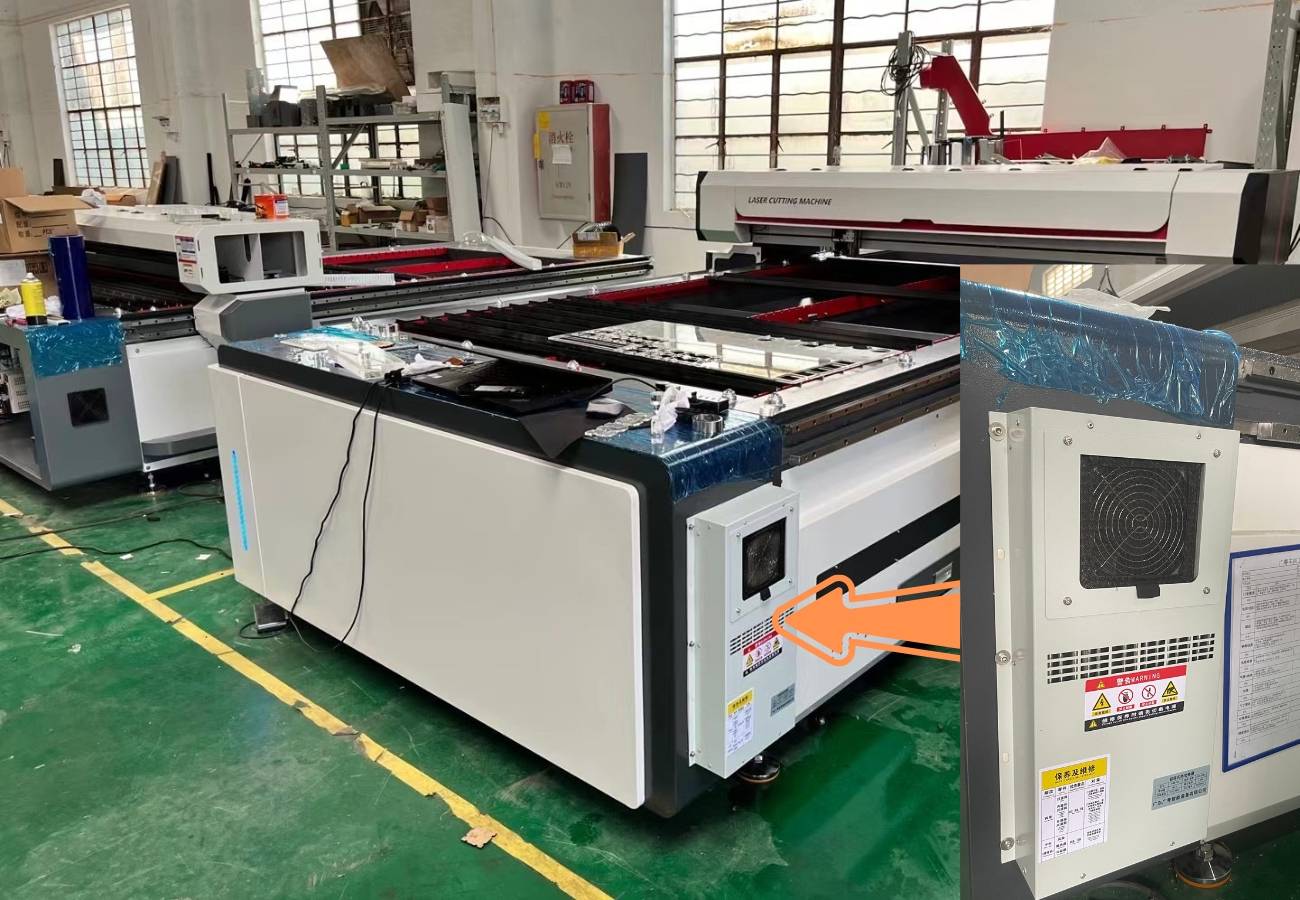

Specialized Independent Industrial Temperature-controlled Air Conditioning

All the electrical components of the flatbed laser cutting machine like servo motor drive, laser power supply, main board power supply, etc. They are placed inside the electrical control cabinet in front of the machine. These electrical components will generate y some heat,but this electrical control box is generally closed.We have to install an air cooling system for this.

Most of the suppliers in the market only install 1-2 fans to the electric control box, our technical staff think that the cooling capacity is not enough, so MOZLASER technician add a professional industrial air conditioning for the cabinet.

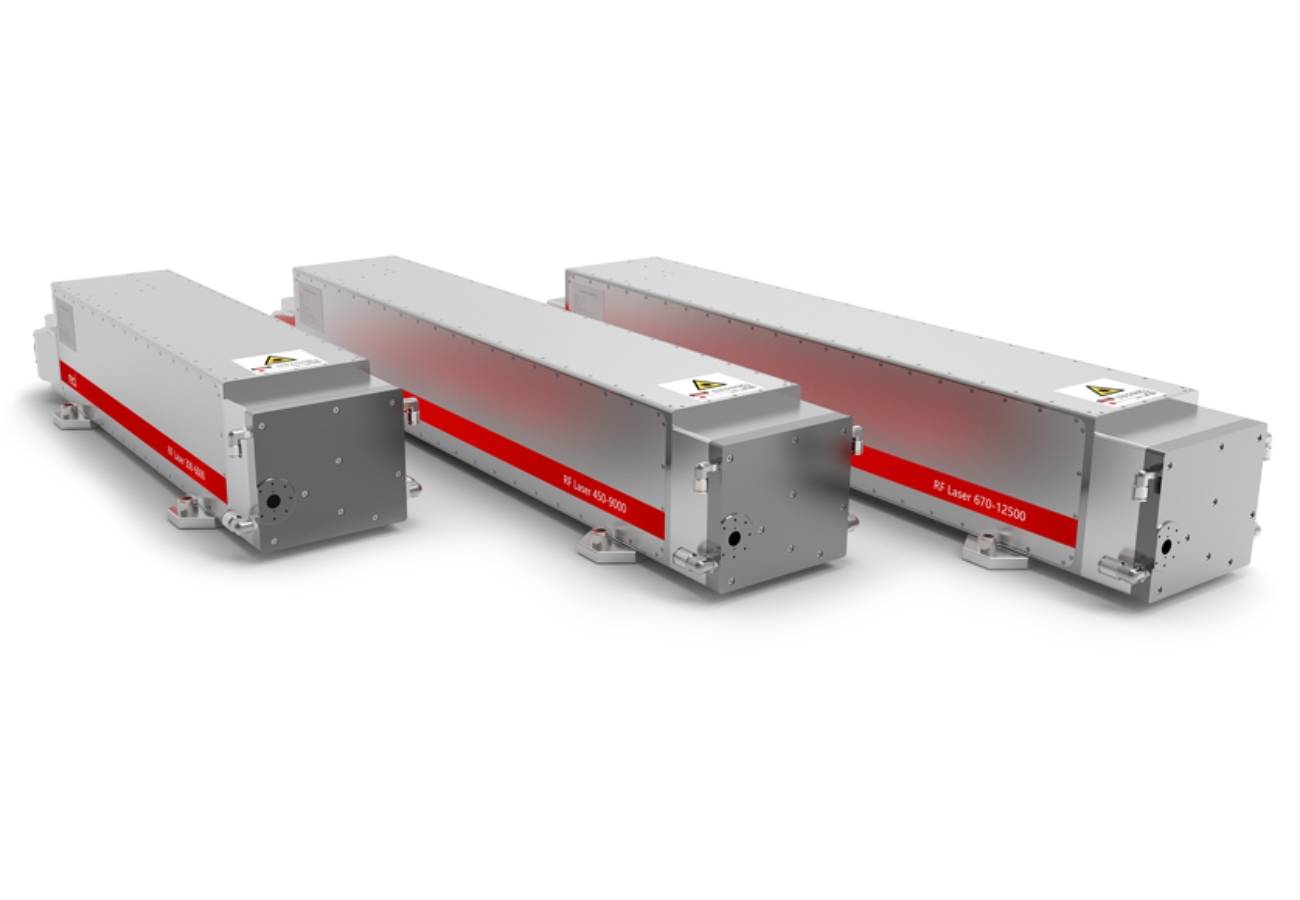

Higher Laser Power Options Than Ordinary CO2 Laser Cutting Machines

The flatbed laser cutter has a wider space for laser tube installation and can match common low power laser tube 80W-150W. If you need higher power to cut thicker plates, we can also match 250W-600W folded laser tube or RF laser tube.

Please contact our team to share your cut materials and cut thickness, as well as the size of your raw material. We will have a customized solution for you.

- Data Sheet

- Package Components Details

- Warranty and Service

Flatbed Laser Cutter

| Machine Model | MZ-1325F/MZ-1530F/MZ-2030F |

| Working Area | 1300×2500mm/1500×3000mm/2000×3000mm |

| Laser Power | Laser Tube 80w/100W/130W/150W or RF Laser Source 250W/400W/600W |

| Laser Head | One Laser Head Standard(Double Laser Head Optional) |

| Control System | RDV6445G Control Board and Panel |

| Transmission System | Dual Gear Rack with Servo Motor |

| Output Interface | Network control,USB control,Wifi Control(optional) |

| Machine Voltage | Ac 220V 50Hz/60Hz |

| Cooling Way | Water Cooling(Industrial Water Chiller) |

| Cutting Speed | 0.1-36m/min(depends on thickness,laser power) |

| Engraving Speed | 0.1-64m/min |

| X/Y Axis Positioning Accuracy | ±0.05mm |

| Repeated Positioning Accuracy | ±0.05mm |

| Graphic Format Supported | DXF,AI,DWG,PLT,etc |

1 year warranty

online service

free parts

use guide

Flatbed Laser Cutter’s Main Application Industries and Materials

MOZLASER has successfully cooperated with customers who cut 86-120 inch PET film, architectural design model chassis painting line, home building materials protection film, a complete set of three-layer, single-layer car airbag fabric, inflatable amusement facilities synthetic materials, yacht sailing, sails, parachute fabric cutting line, filter material fabric, swimwear fabric, special clothing fabric cutting, outdoor fabrics, home decoration fabrics, sponge packaging materials.

And suitable materials also include touch screen PET, OCA optical adhesive, conductive film and optical film, polarizer, IMD, anti-peep film, hardened film, electronic paper, 3M, PET, fabric, leather, paper, wood products, organic glass, rubber, plastic, synthetic materials and other non-metallic materials. Application industry: suitable for photoelectricity electronics, clothing, fabric, leather goods, furniture, packaging, printing advertising, decoration, construction, paper products,templates and other industries need large size raw materials cutting, engraving work of professional-type users.