Titanium and titanium alloys have good physicochemical properties and are increasingly used in a wide range of industries, especially in aerospace. Titanium and titanium alloys are highly corrosion-resistant and generally difficult to corrode. However, in a certain environment, with the increase of service time, the surface of titanium alloy oxide layer is getting thicker and thicker and the distribution of the oxide layer is not uniform. Titanium alloy cutting performance is poor, when using mechanical grinding, it is difficult to control the depth of processing and will produce stress. When the shape and spatial distribution of the titanium alloy to be polished is more complicated, it is more difficult to achieve the expected effect of mechanical polishing. Titanium alloys are often corroded with the HF-HNO3 corrosion system. The corrosion process produces a large amount of nitride gas, and as the corrosion proceeds, a large number of metal ions and hydrogen ions accumulated in the corrosion solution are difficult to deal with.

When the oxide distribution on the surface of the titanium alloy is not uniform and the titanium alloy is thin, the titanium alloy sheet is easily penetrated by corrosion, and part of the oxide layer on the surface of the titanium alloy may not be completely removed. The titanium alloy with 1~20μm thick oxide layer on the surface can be reused after cleaning by laser cleaning machine, which can meet the requirements of engineering applications, thus achieving the requirements of environmental protection and high efficiency. At the same time, through the laser cleaning of titanium alloy surface to make it bright and clean,it means that laser cleaning can replace the traditional pre-treatment process. Laser cleaning machine in the cleaning process, by setting the laser cleaning parameters to control the energy density of the titanium alloy surface. Laser energy density is low, easy to control, will not cause damage to the titanium alloy base material. At the same time by setting the laser cleaning parameters for 1~20μm thick titanium alloy oxide layer cleaning, will not cause damage to the substrate.

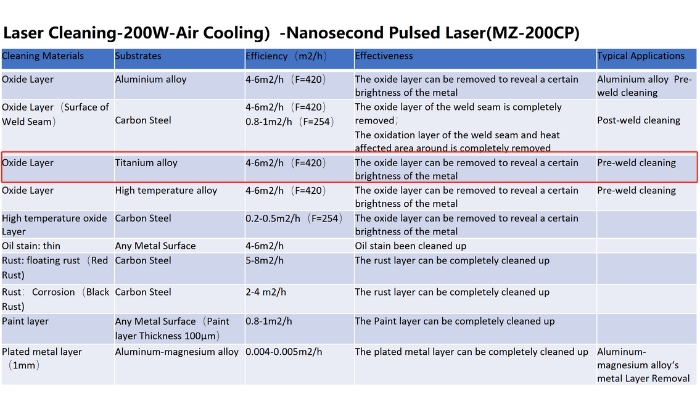

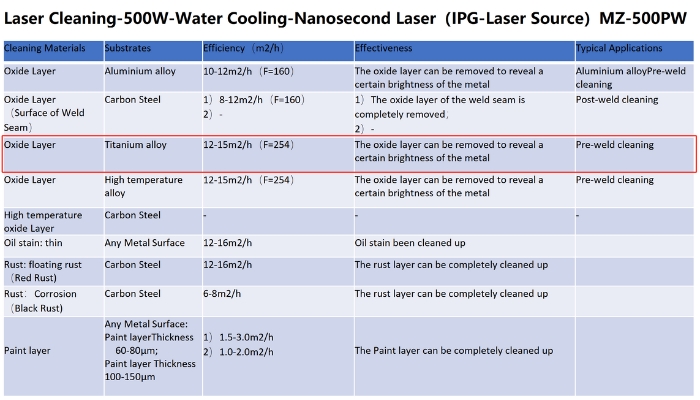

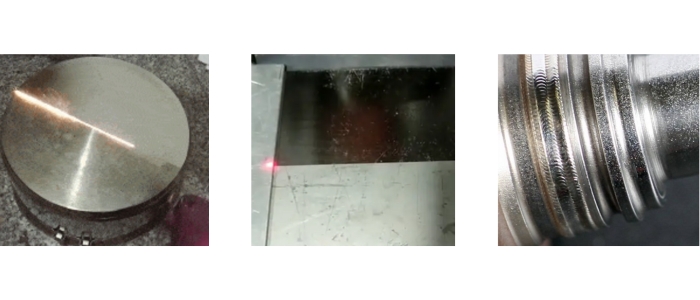

MOZLASER pulse laser cleaning machines series can clean the oxide layer and pollution layer on the titanium and titanium alloy with very well cleaning efficiency. As MOZLASER lab testing data shows that 200W pulse laser can clean 4-6㎡ and 500W pulse laser cleaning can clean up to 12-15㎡. Its really powerful enough for ordinary industries cleaning requests. Below figures* show you what is the difference of 200W and 500W pulse laser cleaning efficiency when you clean the oxide layer on the titanium.