MOZLASER LASER SPOT WELDER

Based on the most popular application fields in the market, the advertising and jewelry industry, MOZLASER has developed laser channel letter welding machine and laser spot welder for jewelry. Compared with traditional electric welding, TIG welding, laser welding is more than twice as fast at least, and the weld seam is more smooth and clean.

- laser welding more eco-friendly welding way of this century

- Laser welding has more wider adaptability to different metal material

- The properties of the laser are better matched to the spot welding function

What is MOZLASER Laser Spot Welder?

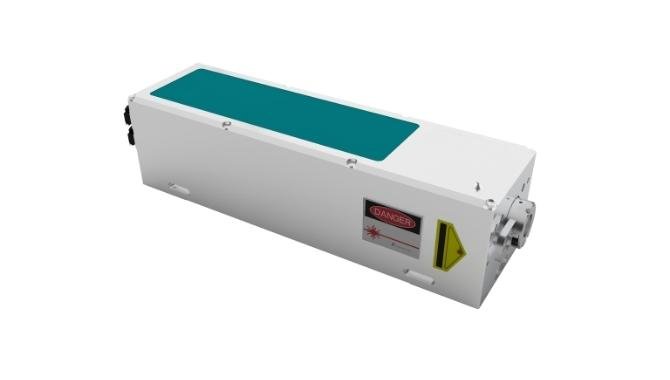

Laser spot welder is kind of The Last Glory of the YAG laser. With the rapid development of laser technology, fiber optic lasers are developing rapidly, as if YAG has become backward and useless. Yes, the fiber laser has its unique advantages, the amazing photoelectric conversion efficiency and excellent continuous light output, which makes it the best in the cutting field. However, MOZLASER engineers have developed Laser spot welder for the advertising and jewelry industry to focus on the advantages of YAG laser in spot welding. Because of the cheaper cost and good performance of welding,it is very popular in the market.

YAG LASERS 200W-500W optional

Exclusive cooling structure for the YAG high heat output

Engineer 10-years YAG laser application experience

Models Of MOZLASER Laser Spot Welder

YAG LASERS 300W laser power, CCD camera and red light position,100*75 CM standard working table.

YAG LASERS 400W laser power, 1.2P water cooling system,100*75 CM standard working table.

YAG LASERS 500W laser power, 2P independent water chiller,100*75 CM standard working table.

YAG LASERS 100W laser power, laser spot welder,10× microscope,CCD Camera monitoring

YAG LASERS 150W laser power, portable jewelry laser welder,laser beam width adjustable

YAG LASERS 200W laser power, desktop type jewelry laser welder,CCD camera and microscope positioning

What Kind of Stuffs Are Suitable for Welding with Laser Spot Welder? (7)

Moz Guarantee

The whole machine two-years warranty, excluding consumables

We guarantee to provide a solution within 24 hours in case the machine shut down

Within warranty time, we send replacement parts for free

Within warranty time, our after-sales service team provides on-site service

The Newest Nd:YAG Laser Source

YAG laser spot welder will send 1064nm wavelength pulsed laser beam then through beam expansion, reflection, focus, radiation heating the surface of the material, surface heat through heat conduction to the internal diffusion, by digital precision control of the laser pulse width, energy, peak power and repetition frequency and other parameters, instantly make the material melt vaporization evaporation, so as to achieve the fucntiong of welding,through the laser welding system.

The Nd:YAG Laser Source power is optional 20W-1000W based on different welding field and truly application scenarios.

Special Large Cooling Capacity Water Chiller for Nd:YAG Lasers

Coolink Pro is the leader of Nd:YAG laser water chiller. As we all know that YAG laser will release huge of heat when the machine is runing.The Cooling Pro uses of dual temperature and dual control water temperature control method, in order to provide stable water temperature for the laser.

At the same time, another cooling path to provide a similar water temperature with the environment to cool the cutting head, welding head and lens, to ensure the stable operation of the overall laser spot welder system.

Flexible Laser Foot Switch for Laser Spot Welder

Laser welding is a delicate task, especially when welding small objects like jewelry, where the operator’s eyes and hands must be focused on the object being welded.

Long-term experience and tests have shown that foot switch can help us to combine our hands and feet to control the laser light flexibly and improve the welding efficiency and accuracy.

We Try Our Best to Solve the Equipment Problems in the Design and Production Process

MOZLASER is committed to providing stable laser equipment to the market and to our customers. As we know, stability and low failure rate are the most important things in equipment products, not fancy features.

The laser spot welder of MOZLASER at least through 7 procedules research and development, factory demo testing, cooperation with old customers on-site testing, expo show, sell to customers, customer feedback, factory development and improvement. This is a closed-loop process.

The Main Application Scenarios of Laser Spot Welder

Laser spot welder is kind of new welding method for advertising industry, welding result is more smooth, no blackening, no deformation, welding firm can be welded stainless steel,aluminum,brass,copper, titanium, rose gold, black titanium and other decorative materials, easy to achieve a variety of font glyphs, patterns, graphics welding process with high efficiency.

Generally, precious metal jewelry is very small and difficult to reach with traditional soldering tools, which makes jewelry soldering, repairing and stone setting has always been a problem.

The laser spot welder makes extremely small welding seams possible because of the welder’s small laser beam and focused laser energy.

Some Advantages of the Laser Spot Welder

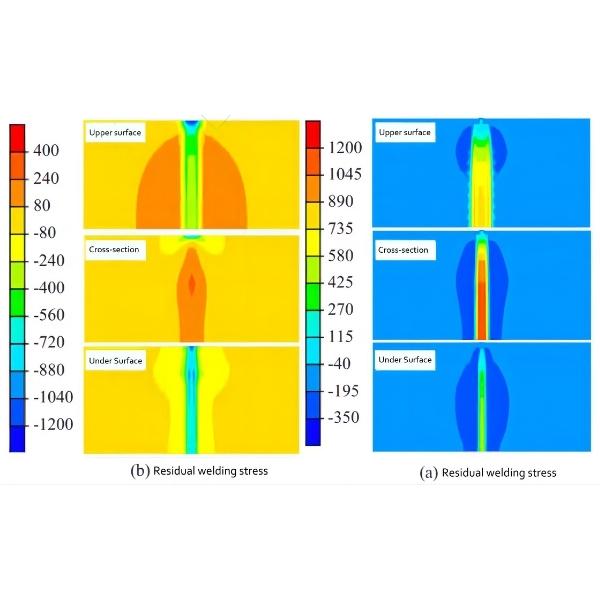

As we all know,after welding process all material will leave welding stress,then make the welding piece to deformate. But Industry data from our research shows that laser welding is 80% less stress than TIG welding,so almost no deformation to the welded material.

The welding scar of laser spot welder is smooth and burr-free, no blackening and no deformation after welding, and the surface does not need polishing treatment after welding.

Laser spot welder almost has no consumables, traditional soldering, argon arc welding and other methods need a lot of consumables energy consumption like solder, argon gas, wire, hydrochloric acid, etc.

Laser welding machine welding without any consumables, and ultra-low energy consumption, working voltage 220V.

High working efficiency, the traditional logo welding using welding tin, argon arc welding and other ways, low efficiency, human fatigue. Laser welding machine breaks through the traditional practice, using red light to quickly find the welding point, CCD direct observation, microscope precise alignment, directional point-to-point welding, faster than ordinary welding channel letters 10-15 times.

Some Welding Samples from Our Clients

- Samples

- Data Sheet

- Details

| YAG LASERS PARAMETERS-Spot Welding | ||||

| Laser Power(Nd3+:YAG Rod) | 200W | 300W | 400W | 500W |

| Max. single-pulse energy | 70J | 90J | 100J | 120J |

| Laser wave length | 1064um | 1064um | 1064um | 1064um |

| Welding Thickness | 0.1-2mm | 0.1-2.5mm | 0.1-3mm | 0.1-3.5mm |

| Beam Diameter | 0.2-3mm | 0.2-3mm | 0.2-3mm | 0.2-3mm |

| Pulse Width | 0.1-20ms | 0.1-20ms | 0.1-20ms | 0.1-20ms |

| Pulse Frequency | ≤50HZ | ≤50HZ | ≤100HZ | ≤100HZ |

| Power Supply | 220V/50Hz | 220V/50Hz | 220V/50Hz | 380V/50Hz |

Please contact us for more details, whether you would like to purchase the equipment for your own use or become a dealer/distributor for your local market, we welcome and appreciate it!

Related Product

In theory, the laser spot welder is a maintenance-free machine, but it has some consumables and wearing parts that need to be replaced regularly.

1). Keep the working environment clean, and the water in the water storage tank must be replaced once a month. Turn off the power when the work is finished.

2). The xenon lamp should be replaced once a year(3,000,000 times lifespan). When ship the machine,there is another lamp for spare. We will send you a video of how to replace it.

3).Protective lens(replace according to the actual situation)

The whole machine two-years warranty, excluding consumables.

During covid-19, we provide whatsapp/WeChat online service to support you how to install and use the machine step by step

Within Warranty time,all the parts for repairing is free,free cost and shipment.

To use this laser spot welder has no need experienced worker, it is quick to get started, no heat deformation after welding, no need to polish and grind.

We promise all our standard models can delivery within 7 days.

If the equipment you wanna purchase is customized model,please talk to our sales for the exact delivery time.

The laser spot welder does not require a computer when it is used. There is a control panel. The three parameters are mainly set on the top.