MOZLASER Stainless Steel Laser Welding Application Development Project

The Application of Laser Welding Stainless Steel is One of the Main Research and Development Directions of the Moz Laser Team.

The Main Research Directions Are,

1. Support and Customer Tracking for Different Stainless Steel Application Industries

2. Traditional Welding Methods in the Stainless Steel Industry

3. Different Thicknesses of Stainless Steel Laser Welding Applications

4. Laser Welding of Stainless Steel Speed and Traditional Welding Methods of Welding Speed Comparison

5. How to Highlight the Advantages of Laser Welding to Replace Traditional Welding Methods.

MOZLASER is One of Your Best Supplier Choices if You Want to Buy a Laser Welding Machine

MOZLASER, Located in the Greater Bay Area in Southern China, Specializes in the Development and Testing of Laser Welding Applications and the Production of Related Laser Equipment. the Company Holds a Number of Patents Related to Laser Welding and Laser Cleaning, Including Welding Laser Heads Patent, Cleaning Laser Heads Patent, Welding Control Systems Patents, and a Series of Other Patents.

We Have Our Own Clean Production Facility, a Excellent Research and Development Team, and a Professional Test Center for Laser Welding Stainless Steel to Test Practical Applications and Drive Product Improvements.

Mozlaser Believes in the Power of Focus, We Have Been Focusing on Laser Welding-related Applications and Long-term Contact with Customers in Related Industries For Years. We Are Making Targeted Product Optimization for Laser Welding Stainless Steel for Different Industries. For example, the Parameters of Ultra-thin Stainless Steel Laser Welding for the Stainless Steel Water Tank Industry.

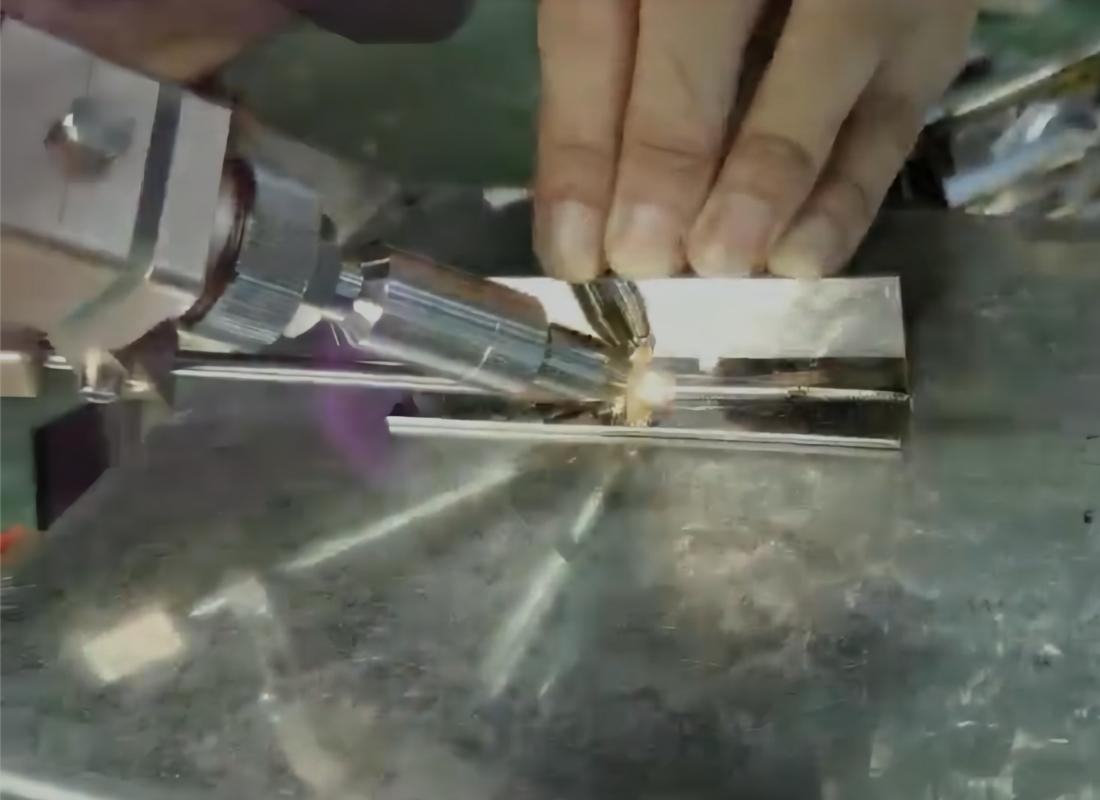

Laser Welding Stainless Steel Testing by Handheld Laser Welder

- Welding of Fish Scale and Straight Line Welding Pattern

- Different Laser Power Options Available

- Mirror Stainless Steel Can Be Welded

- One of the Safest Welding Methods

MOZLASER Has a Wide Selection of Laser Welding Machines with Different Laser Powers (4)

Some Reasons to Choose a Laser Welding Machine for Stainless Steel Welding

What Are the Advantages of MOZLASER Handheld Laser Welding Machine in the Field of Stainless Steel Welding?

- For Laser Welding of Stainless Steel, Laser Power Control is Very Intelligent, and Different Thickness Welding is Very Flexible. As Mozlaser Our Test, the Stainless Steel Material Up to 10mm Thickness, Down to 0.1mm Thickness All Can Be Welded, and Will Not Be Deformed.

- Laser Welding Stainless Steel Generally Uses a Diameter of 0.8-1mm Wire, the Weld Seam is Very Small and Beautiful. for Some Industries That Require Aesthetics, It’s One of the Best Choice for Sure.

- General Use of Stainless Steel Products and Industries Do Not Need to Do Secondary Polishing and Painting Anti-rust Treatment. So the Welding Process is Highly Demanding, There Can Be No Burrs, the Weld Joints Must Also Be Clean and Beautiful. So Laser Welding is Very Suitable.

Electricity Consuption.

Stainless Steel Welding Wire If Needed ( What is the Difference Between Laser Molten Welding and Laser Welding with Wire Feeder?)

Protective Lens of the Laser Head

Welding Nozzles

Usually You Only Need to Set the Laser Power and the Focus of the Welding Head. We Have Specific Parameters for Stainless Steel Welding, Please Contact Us for It.

Recommend to Use Argon Gas

And Nitrogen Works Too

Yes, Please Call Us or Leave a Message for Sample Testing.

All Free and My Pre-sales Team is Gonna Follow You Up.