MOZLASER Fiber Laser Cutting Machines for Metal Materials Processing

Thanks to the advancement of fiber laser technology, fiber laser cutting machines are becoming one of the necessary metal processing equipment for sheet metal processing plants and factories in metal processing related industries.

Fiber laser cutting machine is replacing the traditional high power CO2 laser cutting machine, such as the Co2 laser cutting machine of Trumpf Laser, Amada Co2 laser cutting machine. Because fiber laser has more than 25% higher photoelectric conversion efficiency than CO2 laser, the photoelectric conversion efficiency reaches more than 45%. It is more power efficient and faster cutting speed with the same power.

What are the advantages of metal laser cutter compared to traditional plasma cutting machine?

Ten years ago the traditional sheet metal processing plant or metal processing companies are using plasma cutting machine to cut sheet metal, if the requirements of more sophisticated products to buy high power CO2 laser cutting machine to cut. But the disadvantages of plasma cutting machine is also particularly obvious. Although plasma cutting machine equipment is relatively cheap to buy, but it is too low cutting accuracy, too many burrs in the finished product after the completion of cutting, the need for secondary grinding process, wasting time and manpower.

Furthermore,

The metal laser cutter also has faster cutting speed,thin material triple times cutting speed

With a 45% photoelectric conversion efficiency, it is also more energy efficient

Fiber laser cutting machine has less radiation and less pollution than plasma cutting machine

What Types of Metal Laser Cutter We Have?

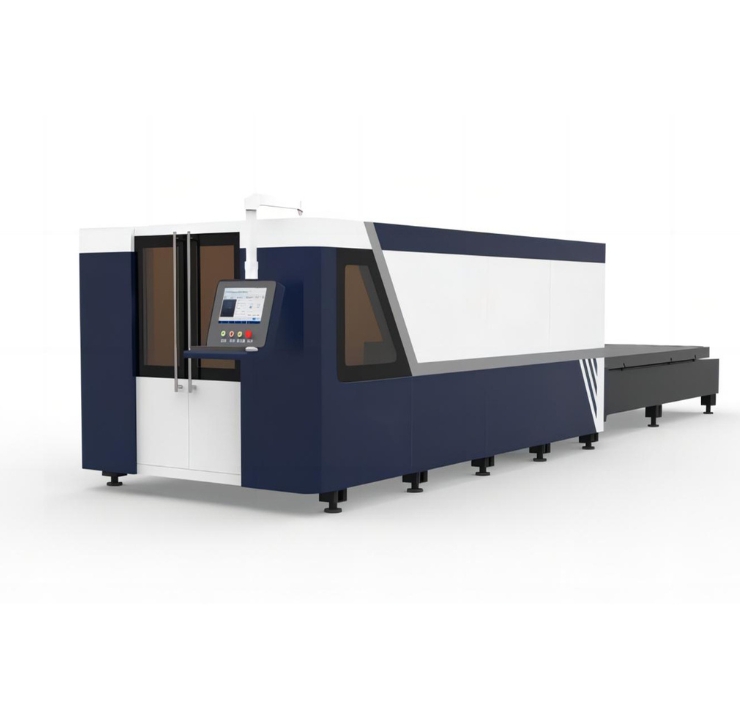

1500×3000mm/1500×4000mm/1500×6000mm

2000×6000mm Working Area Optional

Machine Frames Are Precisely Milled Twice by Milling Machine to Make Sure High Accuracy

Sheet : 1500×3000mm/1500×6000mm

Tube: 120mm/220mm Diameter Chucks

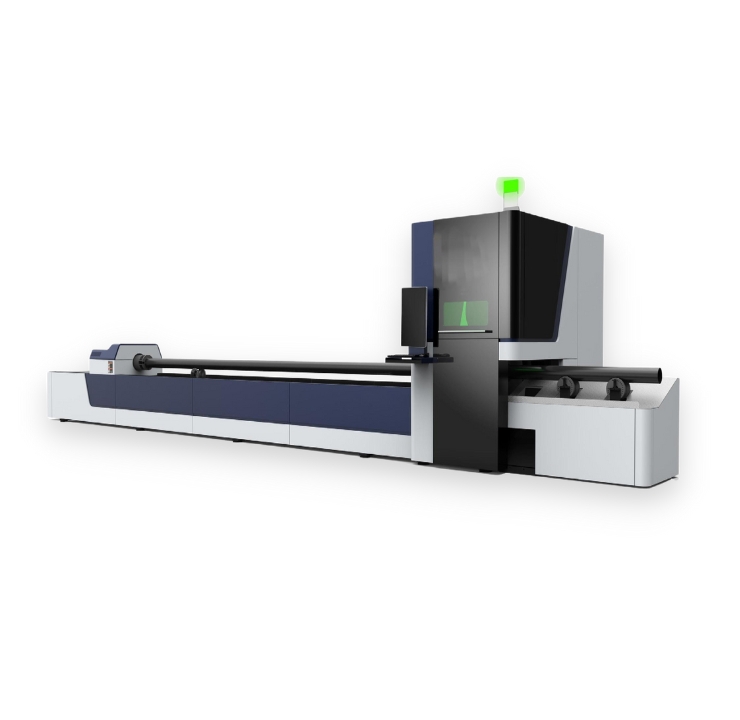

Cutting Sheet Metal and Metal Tubes on the Same Machine

120mm/220mm/350mm/420mm

Chucks and Cutting Diameter Optional

Please Let Us Know Your Raw Material Diameter to Customize the Chuck Size

1500×3000mm/2000×6000mm/2500×6000mm

Working Area Optional

Steel Plate Welded Machine Base Frame,High Temperature Anealed,Twice Accurately Milled

Your Metal Laser Cutters’ power is 1000W-3000W,4000W-10000W,12000W-15000W,20000W-40000W

We Have Air Compressors with Different Flow Rates to Match Different Laser Power

What industries may need a metal laser cutting machine? (8)

Over 20,000 Squares Feet Production Ground and Excellent R&D and Production Team

This year, MOZLASER has set up a special department for the development of fiber laser cutting machines and the development and research of applications for metal laser cutters. Feedback from customers is collected to improve the structure and performance of the machine, such as cutting accuracy and the effectiveness of the machine’s smoke and dust extraction system.

We have over 20,000 square feet of manufacturing facilities in Guangzhou for production, testing and R&D. And have a monthly production capacity of over 30 metal laser cutters.

Industrial-Grade Machine Frame Standards and World-Class Brands of Laser Source

The whole frame of the machine is annealed by over 650℃ high temperature furnace to eliminate internal stress. The internal stress is the main reason for the deformation of the machine, and after the annealing process, the machine will not be deformed even after more than 10 years of use.

Metal processing type equipment durability and resistance to deformation is very important, bad machine deformation will cause the machine’s guide and traditional system accuracy decline, resulting in poor cutting accuracy.

As we all know, metal laser cutting from Co2 laser switch to Fiber laser era, the U.S. IPG brand is the deserved king. IPG fiber laser with its ultra-high photoelectric conversion efficiency and energy efficiency ratio has become the green representative in the field of metal laser cutting.

MOZLASER and IPG China have established a long-term strategic partnership, and IPG has become a strong part of our supply chain. Of course Top 2 brand Raycus Laser is also our strategic partner, you can choose any laser brand you want if you buy metal laser cutter from MOZLASER.

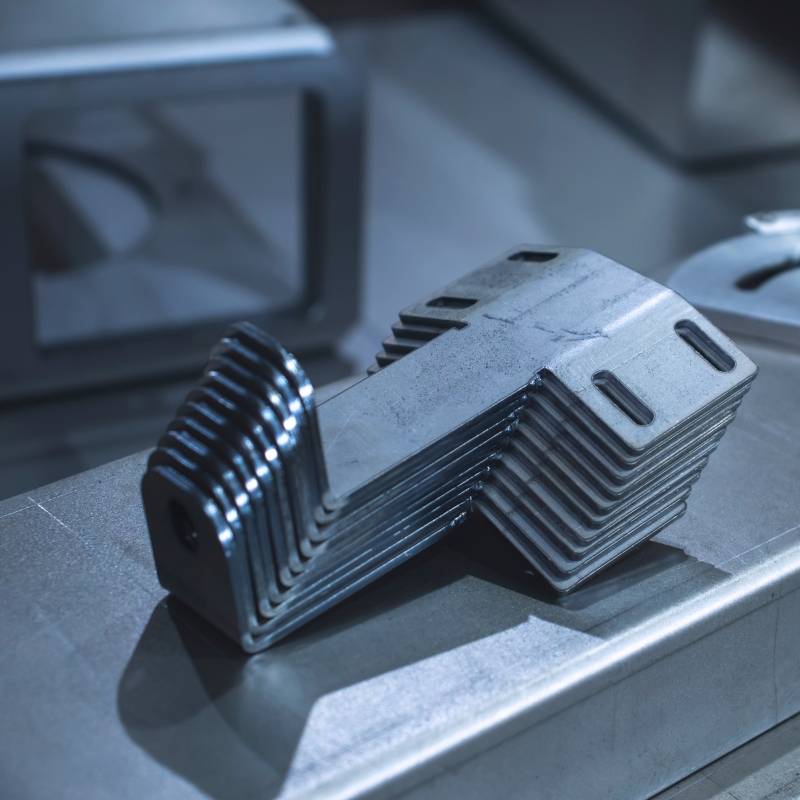

Some Laser Cutting Samples from Our Clients

- Samples

Related Product

- Are you still using traditional punching machines, flame cutting, plasma cutting to cut your metal raw materials?

- Are your customers complaining again and again that your processed sheet metal products are not accurate, do not look good and need to be polished?

- Are you still worried that laser cutting machine is too expensive and it’s very expensive to replace your old equipments such as plasma cutting machine or flame cutter?

- Don’t worry about all this, MOZLASER’s metal laser cutter will solve the above problems for you.

After testing by our technicians, the cutting accuracy of laser machine is more than 10 times than plasma, flame cutting and other equipment. That’s why now fiber laser cutting machine is now speeding up to replace plasma and flame cutting machine. If processing thin stainless steel material, the accuracy of laser cutting will reach ±0.05mm high precision even higher, and with the antioxidant effect of assisted gas(N2), the laser cutting edge is very clean and burr-free, and it will not be yellow and black edge.

And with the advancement of fiber laser technology, the price of fiber lasers has fallen down, unlike 10 years ago when fiber lasers were priced in the hundreds of thousands or even millions of dollars.

Now MOZLASER, with its strong supply chain capability, has gathered all the fiber laser brands in the world for you to choose, such as IPG, nLight, Raycus, Max, JPT etc. The price is very advantageous!