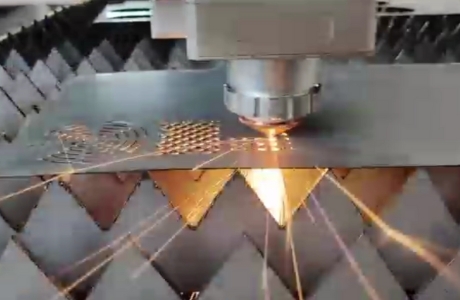

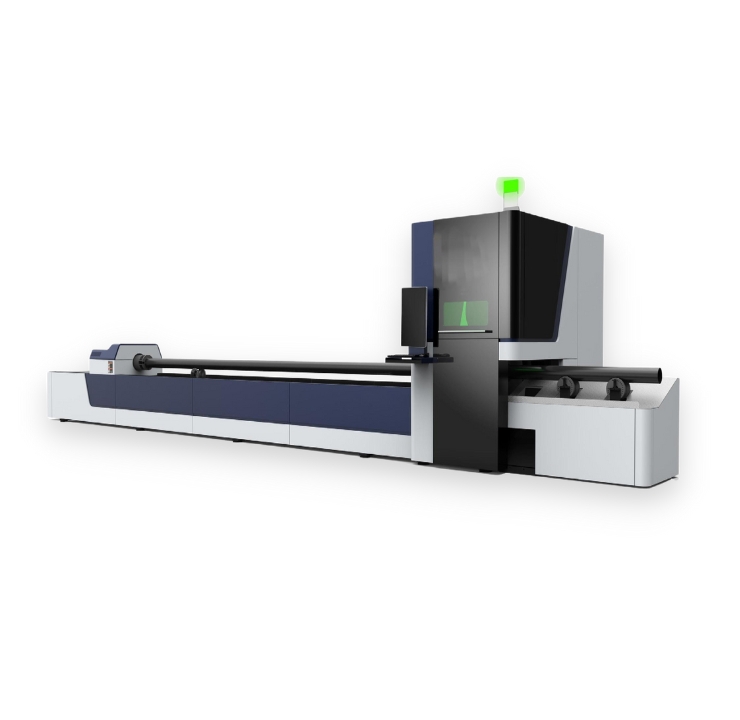

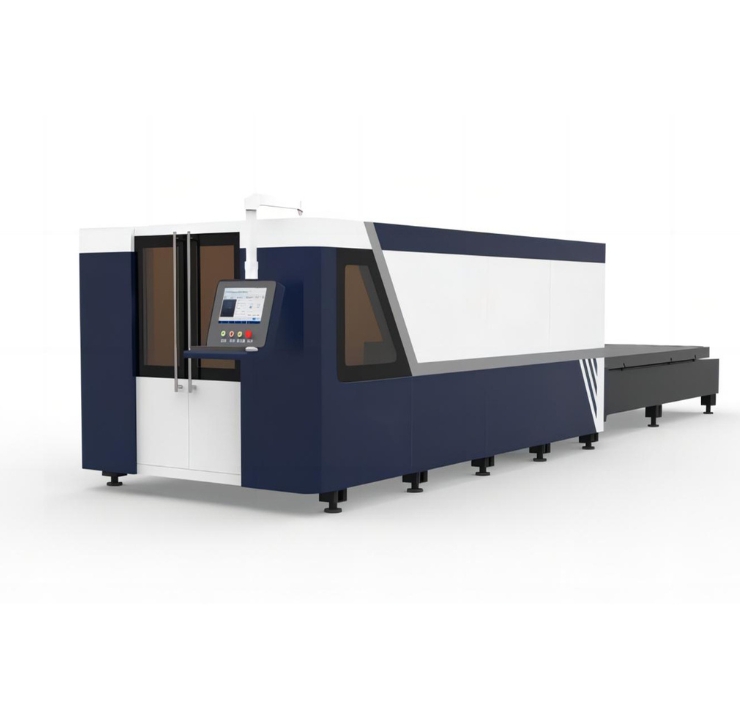

MOZLASER FC Series Metal Cutting Laser Metal Laser Cutting Machine

Single Pallet Fiber Laser Cutting Machine Main Features:

- High Precision,The mounting surface of each fiber laser machine needs to be machined twice by gantry milling to ensure the accuracy of ±0.03mm.

- High-speed,Rack and pinion with high speed servo motor and reducer dual drive system to ensure that the machine running speed of 80m / min.

- Diversity of cutting materials,Two assisted gas systems, low pressure oxygen and high pressure nitrogen (high pressure air) are used to adapt to different material cutting scenarios such as carbon steel, stainless steel and aluminum.

World Famous Brand Fiber Laser

MOZLASER’s metal laser cutting machines uses internationally renowned brands of fiber lasers such as IPG Photonics, Raycus Laser, etc. Fiber lasers are small in size and light in weight for easy installation and support high power structure stability. In the industrial cutting carbon steel, stainless steel, and pure aluminum, brass and other highly reflective materials, than the traditional CO2 laser cutting machine only has faster cutting speed. Fiber laser beam can achieve smaller spot diameter, instant plate thicker, still can provide faster processing speed, greatly reducing the workpiece tolerance. Fiber lasers offer significant savings due to their low overall cost of use. Fiber laser electro-optical conversion efficiency of up to 40% and above, more energy efficient; maintenance-free, eliminating the high annual maintenance costs; in addition to cutting speed, high efficiency, shorten the processing cycle, greatly improving production capacity. Ultra-long pump diode life. Fiber laser pump source using telecom-grade high-power single-core junction semiconductor module, higher beam quality and longer runtime, fiber laser in the use of the process basically does not need to be maintained. Fiber laser has high stability, in a certain shock, vibration, temperature or dust and other harsh environment can still be normal work, showing a very high adaptability.

Industrial Grade Machine Frame Processed by Gantry Milling

MOZLASER metal laser cutter machines’s machine lathe is fully annealed at over 650°C for stress relief, so the whole machine will not be deformed by high temperature and laser burning. Then by double gantry milling process to ensure that the mounting surface is as level as a mirror, so as to ensure the cutting accuracy of the laser machine.

High precision machine lathe structure can ensure the accuracy of the laser cutting machine to ± 0.05mm, while the maximum accuracy of the plasma cutting machine can only to ± 0.5mm. Means metal laser cutter has 10 times higher precision, which is the advantage of the fiber laser cutting machine to cut metals.

Moveable Sectionalized Smoke and Dust Extraction System

Laser cutting machine smoke and dust treatment system: exhaust treatment is generally only for the local operation of the cutting surface, specifically local airflow for treatment, so that the local workplace is not contaminated by harmful substances to maintain a good air environment. General local exhaust unit consists of four parts: air collection hood, air duct, purification system and exhausted fan. Smoke exhaust system can be divided into fixed smoke exhaust system and moveable smoke exhaust system according to the different ways of air collection. fixed smoke exhaust system is mainly used in large CNC cutting production workshop where the operation location and workers’ operation method are fixed, and the position of the air collection hood can be fixed at one time according to the actual situation. Moveable sectionalized smoke exhaust system is relatively flexible in working condition and can adopt different working postures according to different working conditions to ensure processing efficiency and operator convenience.

The structure of our machines all adopt moveable sectionalized smoke exhaust system can efficiently extract and eliminate the smoke and dust generated during the cutting process to ensure the health and safety of your operators.

FSCUT 2000 Model Metal Cutting Machine Controller with Nesting System

CYPCUT is the fiber laser cutting system with the largest market share at this moment. There are many big companies such as Trumf, Amada and other manufacturers still insist on secondary development of CNC system, but CYPCUT’s philosophy is to assist small and medium-sized enterprises to do a good job in laser cutting equipment. Small and medium-sized enterprises do not have the technician and ability of CNC control system, they can directly take CYPCUT laser cutting system for integration and debugging.

The biggest advantage of CYPCUT system is that it has a large market share and low price, and the overall page is simple and user-friendly to operate, which is good for ordinary operators. If a sheet metal fabricator purchases a metal laser cutter with the CYPCUT system, no experienced technician is needed, just a simple training can start the operation.

Swiss Technology Raytools Automtic Focus Laser Cutting Head

Raytools, one of the world’s leading brands of laser cutting heads, is very popular in all countries, not only because of its beautiful appearance but also because of its unique structural sealed design and stability.

The most important thing about the laser head is its water-cooled temperature control system and dust protection system. The Raytools series laser cutting head is designed with three layers of protective windows, which can effectively prevent dust and reflected laser beam from damaging the internal focusing and collimating lenses. It also effectively blocks the reflected laser from burning the laser source’s module. In addition, it incorporates a water cooling module with independent circulation to prevent the laser cutting machine from overheating during operation.

Super Speed Dual Gear Rack and Servo Motor Driving System

MOZLASER’s “FC” series metal laser cutting machines are all driven by a dual gear rack and pinion. The high precision grinding gear rack, linear guide and high speed servo motor allow the machine to run at a speed of over 80m/min. And it also can ensure the cutting accuracy and repeat positioning accuracy of the machine.

This double gear rack drive transmission system can well guarantee metal laser cutter in cutting thin stainless steel sheet, thin carbon steel sheet and other materials can reach more than 30m/min. If the traditional screw driving system is used, it can only reach about 12m/min.

Double Independent Circulation Industrial Water Chiller

Laser machines use industrial water chillers mainly for cooling fiber lasers, because lasers generate a lot of heat in the process of producing laser light. So the industrial water chiller is crucial for the stable operation of the laser cutting machine.

And we use S&A water chillers with more than 10 years of history and a very high share in the market. And it has independent dual cycle cooling design, which can cool the fiber laser and the laser cutting head separately to ensure the metal laser cutting machines can run stably.

- Data Sheet

- Package Components Details

- Warranty and Service

Metal Laser Cutting Machine

| Machine Model | MZ-1530FC | MZ-1540FC | MZ-1560FC | MZ-2040FC | MZ-2060FC |

| Working Area | 1500×3000mm | 1500×4000mm | 1500×6000mm | 2000×4000mm | 2000×6000mm |

| Laser Power Options | 1KW/1.5KW/2KW/3KW/4KW/6KW | ||||

| Max Running Speed | 80m/min | ||||

| Max Acceleration | 1.2g | ||||

| X/Y Axis Positioning Accuracy | ±0.05mm | ||||

| Repeated Positioning Accuracy | ±0.01mm | ||||

| Machine Voltage | AC 380V 50Hz | ||||

| Cooling Way | Water Cooling(Industrial Water Chiller) | ||||

| Machine Max Load Weight | 0.75T | 1T | 1.3T | 1.5T | 2T |

| PARAMETERS FOR REFERENCE ONLY, CUSTOMIZATION SERVICE IS AVAILABLE | |||||

2 year warranty for whole machine except consumables.

MOZLASER “FC” series single pallet metal laser cutting machine

Metal laser cutting machines are currently replacing a large number of traditional cutting methods in industrial processing, such as plasma cutting machines, punching machines, flame cutting machines, and Co2 laser cutting machines. It has become the core force of modern industrial upgrading.

Metel laser cutters are widely used for cutting and processing various metal materials such as stainless steel, carbon steel, aluminum, aluminum alloy, brass, titanium alloy, etc. They are highly adaptable for cutting metal materials. For different thickness of metal materials, fiber laser cutters only need to adjust the corresponding laser power to complete the cutting application. No matter where you are in the industrial process, from 3C to electronics to aerospace, automotive, shipbuilding, laser processing is a necessary equipment.

MOZLASER’s fiber laser cutting machines have industrial grade structure design, with high-speed servo motor, fast cutting speed, and integrated CYPCUT control system, can be multi-stage perforation, flying cutting, greatly guarantee your work efficiency and save time and labor.