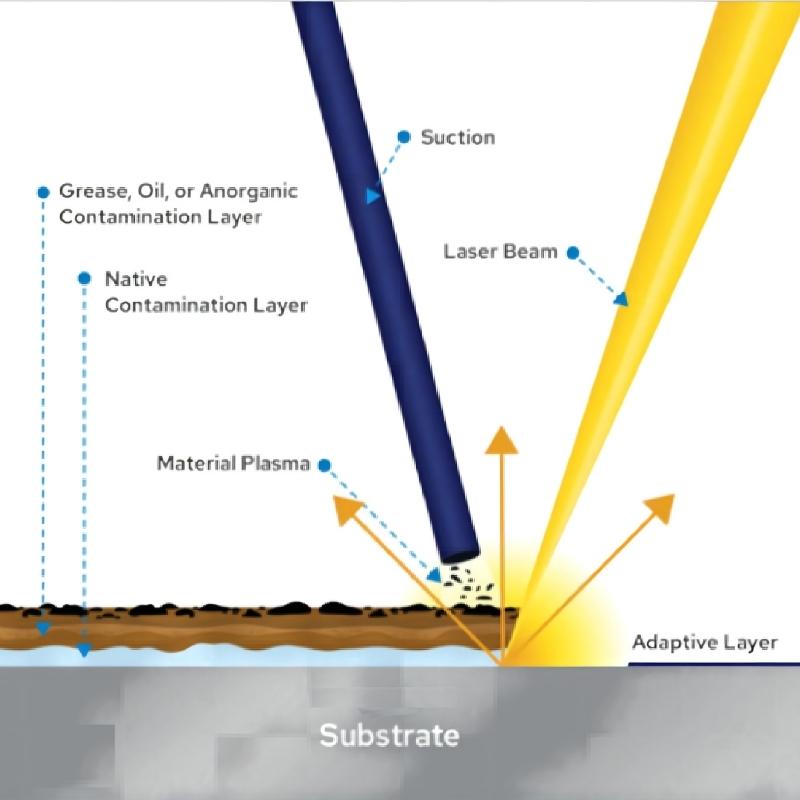

Laser Cleaning uses a Narrow Pulse Width, High Power Density of Laser Beam to Scan the Workpieces’ Surface. In the High Energy Laser Beam Irradiation Under the Contamination Layer’s Vaporization, Decomposition, Plasma Stripping, and Other Mechanisms Together. So That the Dirt Layer Can Be Quickly Stripped from the Substrate, to Achieve Surface Cleaning. At Present, There Are Two Main Types of Laser Cleaning Machines, Mainly Including Nanosecond Pulse Cleaning Machines, Which are Characterized by Non-damage Cleaning, Used for High Precision Cleaning and Paint Removal, and Heritage Cleaning. The Other Are Continuous Laser Cleaning Machines, Using a Continuous Fiber Laser Source, Continuous Fiber Laser Sources have More Competitive Prices so this kind of laser Cleaning machine is Mainly Used in Large-scale Rust Removal. (MOZLASER Definite it Laser Rust Removal Machines)

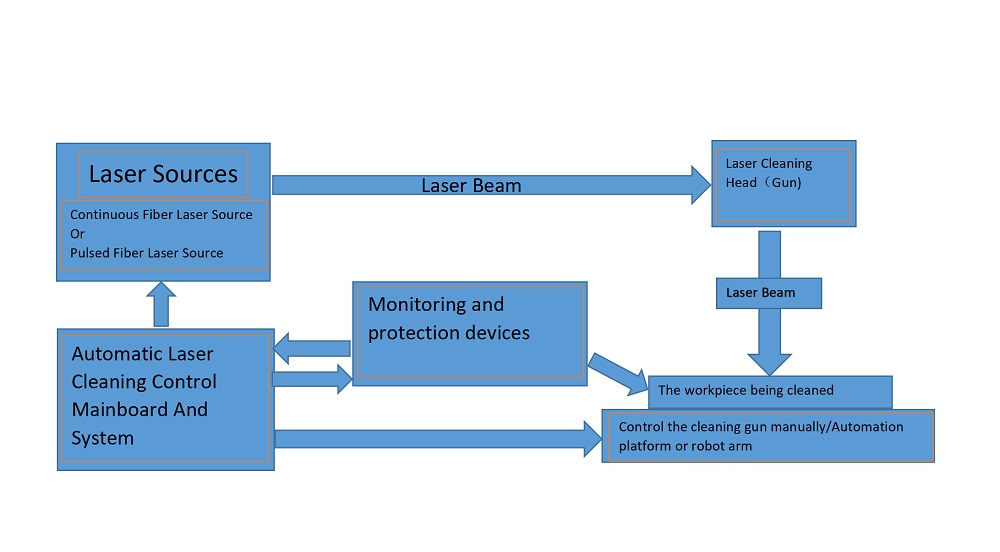

A laser Cleaning Machine is Generally Composed of Laser Source, Laser Cleaning Head (Cleaning Gun), Automatic Control Operating System, Cleaning Monitor and Protection Unit, Automation Platform, Etc.

Some Practical Application Examples of Laser Cleaning:

1. Laser Cleaning of the Icon on the Altar

The Altar of Albertino in Italy Was Built in the Middle of the 14th Century. Due to the Long Period of Time, the Surface of the Icons on the Altar Was Covered with a Layer of Carbon Black and Plaster Several Millimeters Thick, Which Seriously Affected the Appearance of the Relics. in Order to Restore the Ancient Color of the Icons, It Was Necessary to Use Cleaning Means to Remove the Crusty Layer, Which Was Evaluated by the Heritage Organization and Determined to Be Achieved by Two Connoisseurs from Italy and Austria Using Laser Cleaning Technology. They Used a Laser Wavelength of 1064nm, Pulse Width of Less Than 10ns, the Diameter of the Laser Spot is Greater Than 2.5mm, the Energy of 1200mj, the Laser Uses Fiber Optic Transmission, to Achieve a Large Area of Remote Image Cleaning, Cleaning Efficiency of 1 ~ 1.5m2 / Day, After Cleaning to Restore the Image of the Old Appearance of the Ancient Color.

2. Laser Cleaning Mold

We Used Q-switched Nd: YAG Pulsed Laser with a Wavelength of 1064nm, Pulse Width of 200ns, Laser Spot Diameter of 0.09mm, Energy Density of 0~85.0j/cm2, Laser Scanning Speed Range of 0~2000mm/s to Laser Clean the Rubber Layer Covering the Surface of Tire Printing Mold and Automobile Tire Mold, the Thickness of Rubber Layer is 16μm. the Scanning Speed Used in the Experiment is 300mm / S, at an Energy Density of 71.2j/cm2 to Achieve a Complete Cleaning of the Rubber Layer on the Surface of the Mold, Without Any Damage to the Surface of the Mold Substrate, the Cleaning Efficiency of 0.4m2 / Day.

Laser Cleaning Technology Has a Bright Future

Laser Cleaning Technology Has Developed Rapidly in the Past Two Years, Whether It is the Laser Cleaning Process Parameters and Cleaning Mechanism, Cleaning Object Research or Application of Research Has Made Great Progress. However, in Laser Cleaning Technology After a Lot of Theoretical Research, the Focus of Its Research is Constantly Biased Toward the Application of Research, and in the Application of Promising Results. Due to the High Cost of the Laser and Its Supporting Hardware, So That the Scope of Application of Laser Cleaning Technology is Greatly Limited, Especially in the Low-cost Object Cleaning is Difficult to Afford. Future Laser Cleaning Technology in the Protection of Cultural Relics and Works of Art Will Be More Widely Used, and Its Market Prospects Are Very Broad. with the Development of Science and Technology, if the Cost of Lasers and Their Hardware Continues to Decline, the Technology in Industry Will Also Become a Reality, and Its Application Will Be Broadened.