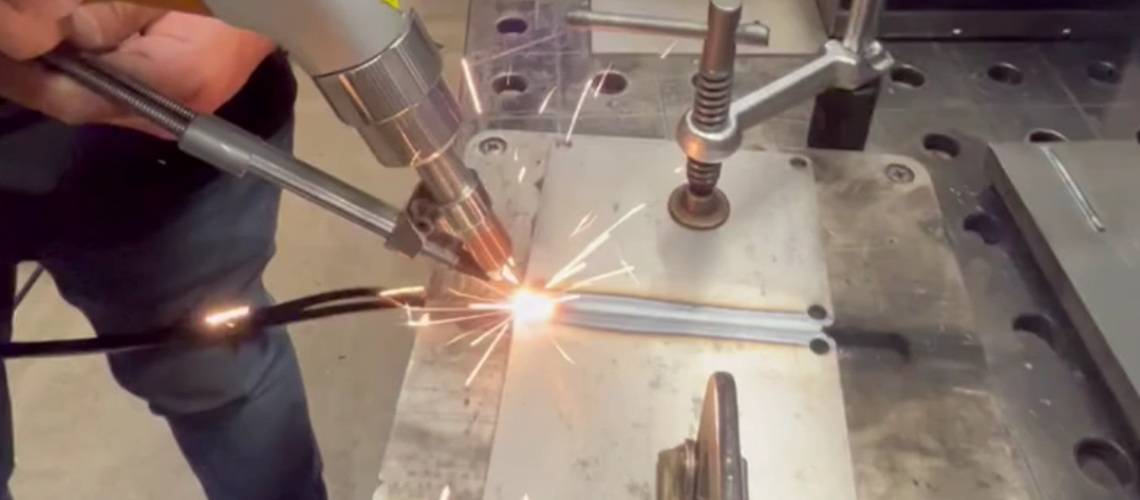

Single wire feeder and double wires feeder solution of IPG LightWELD

All the components connected to IPG LightWELD are available like steel feeding pipe,teflon feeding pipe,gun clip,contact tip,welding nozzle,etc.

- 100V-240V 50/60Hz electric power supply,wide country and area use.

- Independental on/off relaying signal port with signal cable.

- High speed wire retract function when you finish your welding process.

- Powerful DC motor to make sure feeding speed matches laser welding speedy feature.

- Customzable electric cord,American type cord,EU type,British type,all available.

- Single wire feeder

- Double wire feeder

- Packges details

| Single wire feeder | ||||

| 1. Wire feeder color (customizable) 2.Power supply: AC 110V-240V 3.Motor: DC permanent magnet 4.Wire size:0.8mm,1.0mm,1.2mm,1.6mm 5. Wire feeding speed: 0.5-1.8m/min 6. Maximum rotation speed: 1700Rpm Extra Specifications: 1. English language contral panel 2. Signal port to LightWELD( Feed and Stop) 3. Wire feeder size:720×390×480MM N.W: 29 KGS 4. Package size: 810×450×540MM G.W: 38 KGS |

| Double wire feeder | ||||

| 1. Wire feeder color (customizable) 2. Power supply: AC 100V-240V 50/60Hz 3. Motor: DC permanent magnet 4. Wire size: 0.8mm,1.0mm,1.2mm,1.6mm,2.0mm 5. Wire feeding speed: 0.5-1.8m/min 6. Maximum rotation speed: 1700Rpm Extra Specifications: 1. English language contral panel 2. Signal port to LightWELD( Feed and Stop) 3. Wire feeder size:720×390×480MM N.W: 29 KGS 4. Package size: 810×450×540MM G.W: 38 KGS |

Plywood Case with shock-proof foam(Air shipment standard)

2nd generation integral ABS injection molding wire feed roller drive device

Compared to the first generation metal body wire feeder (wire feeder for TIG and other traditional welding methods) the integral ABS injection molding roller drive device uses less combinations of parts, resulting in higher precision and smoother wire feeding performance.

Moreover, MOZ special smooth oil is used between the wire feeding roller drive device and the motor, which has been tested to be less noisy than normal wire feeding mechanisms in the market, and faster wire feeding speed under the same motor power.

Stable and reliable traditional pushbutton membrane switches

Wire feeders are assistant equipment for various welding machines, we focus on the core function of the wire feeder to minimize the possible maintenance costs at a later stage. Tested pushbutton membrane switches are the most stable, have the lowest failure rate and are easy to replace.

Why don’t choose the touch screen on like other supplier on the market? We have also tested the touch screen design that is popular in the market nowadays. The later maintenance cost of the touch screen is too high, and the wire feeder does not need to change too many settings and parameters during the using process, so the touch screen is not the best choice.

The most useful function restract welding wire when your welding rprocess done.

In-depth development and application of the wire feeder function, the most popular wire feeder control system today, with the addition of the wire restraction function. Experienced the use of hundreds of local customers feedback, we developed this function to solve the wire sticking problem when your welding process is done espeically IPG lightWELD laser welding system.

At the same time, this feature is also very helpful in solving the problem of wire sticking if conventional TIG/MIG welding industry use our single wire feeding or double wire feeding system.

Reverse wheels design for easy movement at will in your welding factory

The wire feeder may need to be moved to where you want to weld in your work place just like your IPG lightWELD welding system. That’s why IPG lightWELD has developed a movable welding cart. We have designed our wire feeder with universal wheels so that you can easily move it anywhere in your welding factory or welding workshop.

MOZLASER Market-proven single wire feeder and double wire feeder systems.

Been tested,MOZ wire feeders can matches IPG LightWELD welding system perfectly and MOZ company can provide related wire feeding components at the same time. MOZLASER’s wire feed system is compatible with most laser welding machine brands, such as IPG LightWELD, MOZLASER laser welder, Dapeng laser welder, united winners, Oree laser, Han’s laser, HGTECH, and many others. Our single and double wire feeders was developed on the base of conventional TIG/MIG welding systems, so that at the same time our wire feeders can also be used in conventional TIG/MIG welding systems.

For the wire feed speed changes in robotic welding, we have developed a wire feed speed change module together with a software development company, which can realize 0-10V, 0-5V voltage change speed and simulated voltage change speed in conjunction with the MOZ single wire feeder and double wire feeder. Whether you want to develop a laser welding robot or a conventional TIG/MIG welding robot with wire feeding system, you can choose MOZ wire feeders.